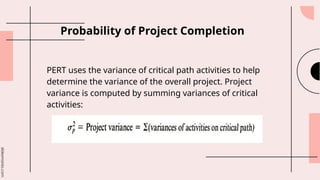

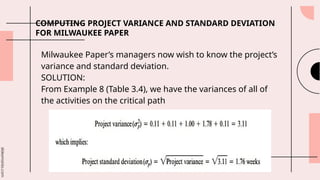

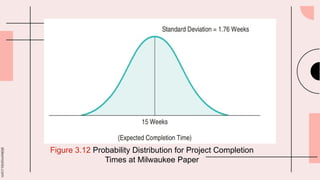

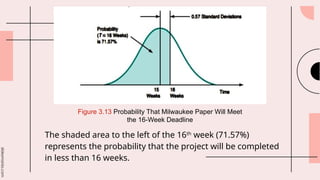

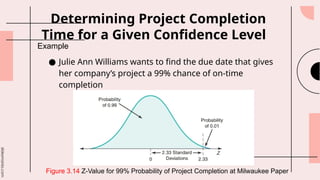

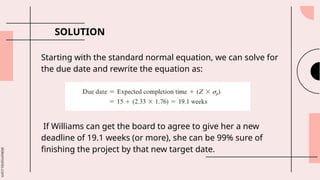

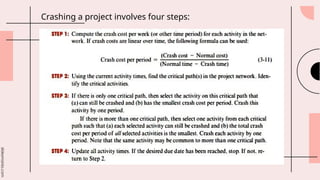

This document outlines the fundamentals of project management, including planning, scheduling, and controlling projects through techniques like PERT and CPM. It emphasizes the importance of effective project management in ensuring timely, budget-compliant, and quality project completion while discussing risk mitigation and resource management. Additionally, it covers topics such as critical path analysis, project variability, cost-time trade-offs, and project crashing to meet tight deadlines.

![slidesmania.com

ty Distribution

with Three Time Estimates

● To find the expected activity time,

t, the beta distribution weights the

three time estimates as follows:

t = (a + 4m + b) 6

∕

● To compute the dispersion or

variance of activity completion

time, we use the formula:1

Variance = [(b a) 6]2

− ∕

Figure 3.11 Beta Probability Distribution

with Three Time Estimates](https://image.slidesharecdn.com/operationsmanagementprojectmanagement-241001101505-f298dc9d/85/Operations-Management-Project-Management-pptx-43-320.jpg)