This document provides instructions for operating an OP series operate panel, including:

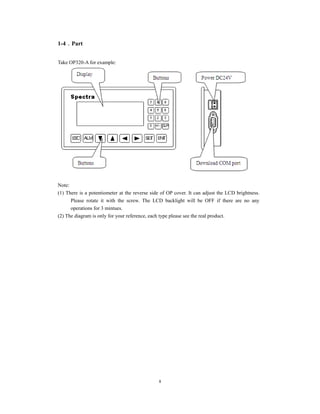

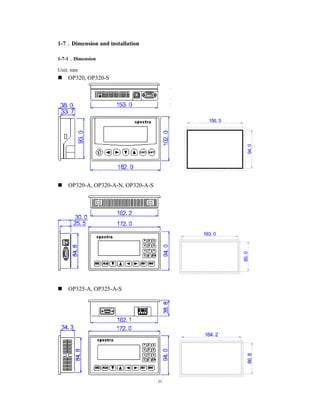

- The OP series includes basic hardware specifications, dimensions, installation instructions, and descriptions of button functions.

- It outlines how to troubleshoot issues like inability to download programs or communication problems with PLCs.

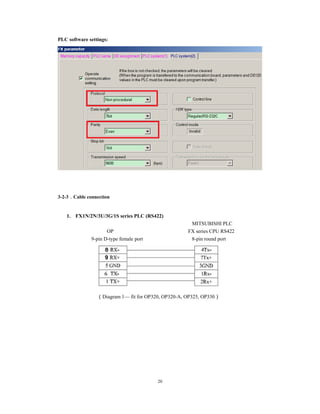

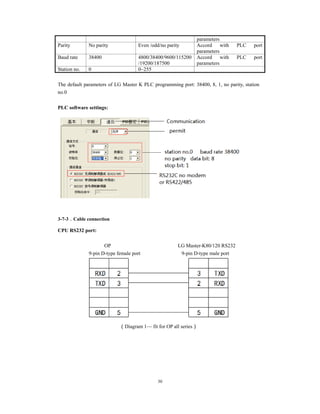

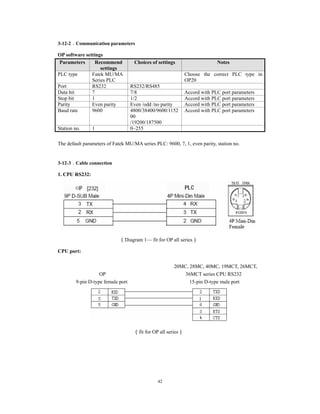

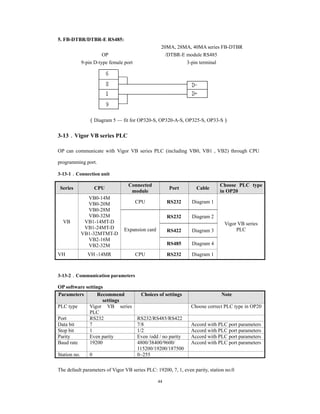

- Detailed connection instructions are provided for interfacing the OP series with over 15 popular PLC models, including Mitsubishi, Omron, Siemens and others.

- The document contains answers to common questions about using the OP series, and information on program security.