This document is the seventh edition of the IET Wiring Regulations (BS 7671), which is the national standard for electrical installation work in the UK. The document provides regulations and guidance for electrical installation design, inspection, and testing. It covers topics such as protective measures, earthing and bonding, cable selection and support, operation of residual current devices (RCDs), and more. The IET publishes updated editions of the Wiring Regulations to incorporate new information and changes to legislation.

![@

:;I

"'

:::>

~

::::0.'

c:

c:t.

0

:::>

a

g'

<><>.

:::>

r:::

~

~0

"' :::J

5.0-l

;;t rtf

n

::r Cl

~ c:

co.:

~ro

-

.,.

-

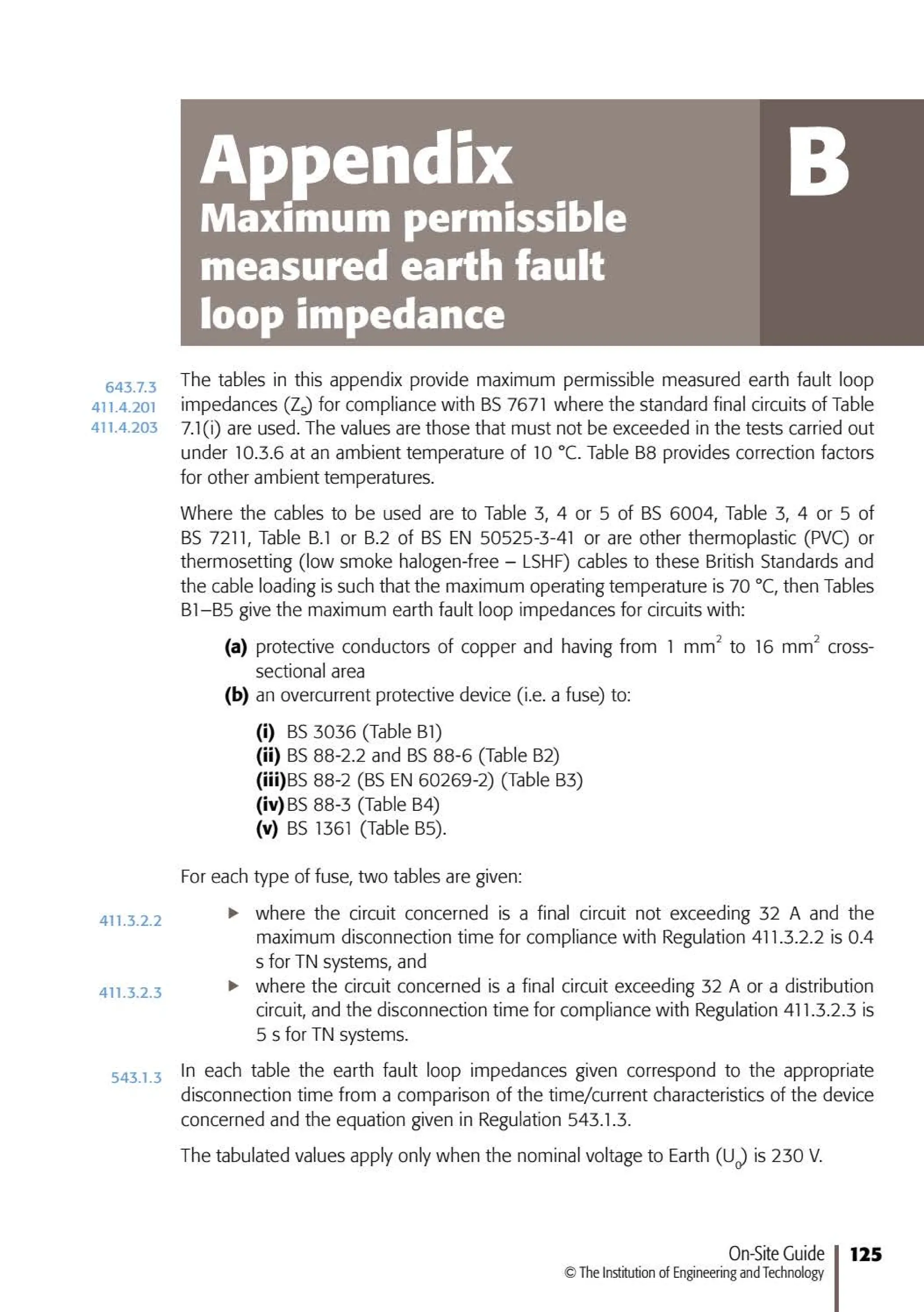

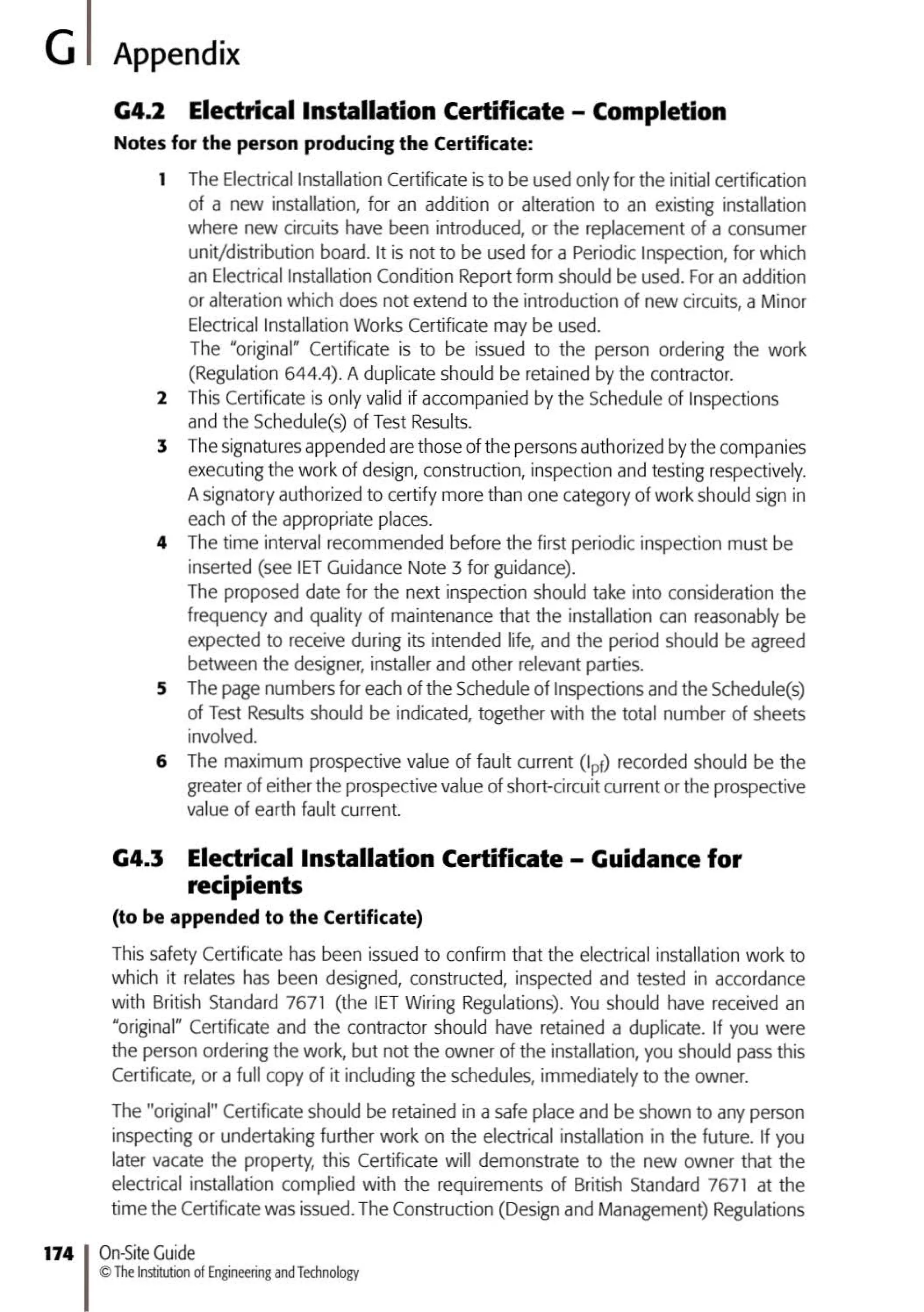

T Table 86 Circuit-breakers. Maximum measured earth fault loop impedance (in ohms) at ambient temperature where the overcurrent

device is a circuit-breaker to BS 3871 orBS EN 60898 or RCBO to BS EN 61009

0.1 to 5 second disconnection times

1

2

-

B

-

3&C

14.56 8.74

8.4 5.0

11.65 7.0

5.82 3.49

7.28

4.2

5.87

2.91

4.4 2.93 2.76 2.2 1.76 1.47 1.38 1.1 0.98 0.88 0.7 0.44

2.5 1.67 1.58 1.25 1.0 0.83 0.79 0.63 0.56 0.5 0.4 0.2

~

3.5 2.3 2.2 1.75 1.4 1.17 1.1 0.88 0.78 0.7 0.56 0.35

1.75 1.16 1.09 0.87 0.7 0.58 0.55 0.44 0.38 0.35 0.27 0.17

Circuit-breakers. Maximum measured earth fault loop impedance (in ohms) at ambient temperature where the overcurrent device is a

circuit-breaker to BS EN 60898 t e D or RCBO to BS EN 61009 t e D

Circuit-breaker

type

D 0.4 sec

05 sec

r:l

1.46

2.91

iii]

0.87

1.75

ml

0.55

1.09

mJ

0.44

0.87

Circuit-breaker rating (amperes)

li'lil

0.35

0.7

~

0.28

0.55

Hi] liD] ~

0.44 0.35 0.28 0.17

Regulation 434.5.2 of BS 7671:2018 requires that the protective conductor csa meets the requirements of BS EN 60898-1, -2 or

BS EN 61009-1, or the minimum quoted by the manufacturer. The sizes given in Table 87 are for energy limiting class 3, Types Band Cdevices

only.

)>

""0

""0

(I)

::s

c..

-·

><

OJ](https://image.slidesharecdn.com/on-siteguidebs76712018electricalregulationspdfdrive-240102212345-20c7c62c/75/On-Site-Guide-BS-7671_2018-Electrical-Regulations-PDFDrive-pdf-132-2048.jpg)

![Symbols

A Sc..::o.a-outlt"': mlntellJdtllg

Wl".ltrument Ot

~

,.,.., f(hed e11ergy meter

s.::xlo.et-out et • ~unctcn

W'l • WJt1 l'lour

d' S'• !ch VArh •Volt

Jl' 2 way 5Wtch,

ampt>r~ re;Jctlle

hour

single pole

X lnterrneodll!te ~ Mo!Of SIJI!• r,

SWllCh ~'I)L•fdl !>'yTnbol

Pull S..'1tch, IX] C,taH1clt.l

eft s•ngle·pole ~.l .lll!._'f

........... HuoH

"S(.:ent

~

fuse,

lum na.re rated curft'nl

lllJOl~

X

tmt T,SMCV

ltrtng 9 Opfl'fatlng

lurl na re (or rl"""e (cool)

-;,~(1.11 (i!"C:Ui!)

SeH<Dntalned

~

•.1.tlte (l")rwtKt,.

~

r11 ·m~t!y :;>en

e-rn~

--st ~1118

r!• air. l31tat..

,J"l nan

.,...,.!'ydosed

@ Pd>httln

I Morualv

~....!- llld!::""~

~-""i .,etared"""""

o~:>

e)c.:x• 6. Tive<-phas<o

.......q. Jclt.l

lfr

Al:,)L:ll(.

...gr.d :.ngdevice y r~

g{'f -..o-,a symbol ......one..w

(OJ!. bell)

-0-=notU5ed

11' Ruzw

on IEC~rds

'i:Y Telephone

han&~ ~ Rect1her

0 M~< rcphone (%1 r.ven.cr

c(J Le>udspeakef -tJ- BMk"V ol

pnrnary or

'r Antenna st..:ot'ldluy cclls

$

0 Mach•ne lr.m..,form~·t

• F'unaion ~·nt•ral ':.yrnbol

M MOIOt' w1

th two wu"':i ngs

C = Cenef(l!Or

@] StJIIC getl(•f,ttOI 10' t •l!o' c.

0 /<>~mete<

10 n~J M

10' lulo k

@ Armleter

10

"'" "'

10 n1:10 u

SGT 2AY

Ttie only guiile to BS 7671 written l>y the Wiring

Regulations experts at the lET, ttie On-Site Guide

contains clear, concise guidance to ttie technical

information contained in the Regulations:

ISBN 978-1-78561-442- 2

9](https://image.slidesharecdn.com/on-siteguidebs76712018electricalregulationspdfdrive-240102212345-20c7c62c/75/On-Site-Guide-BS-7671_2018-Electrical-Regulations-PDFDrive-pdf-218-2048.jpg)