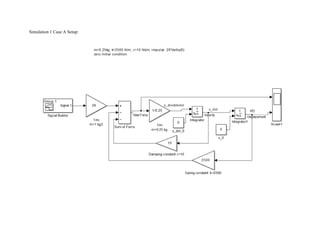

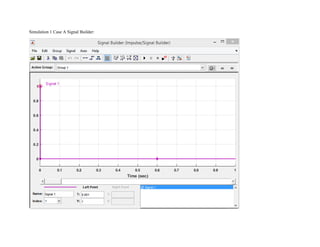

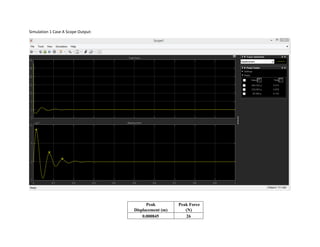

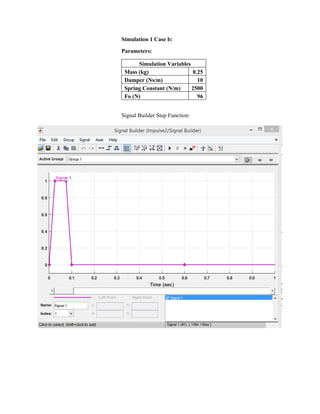

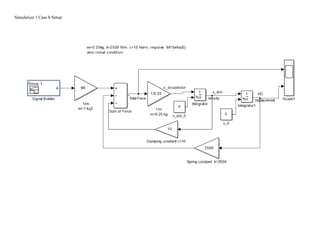

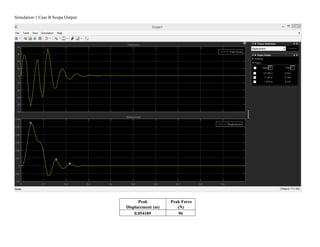

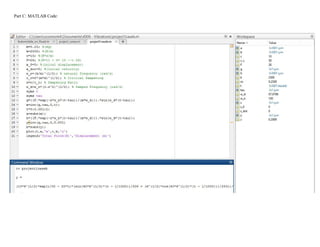

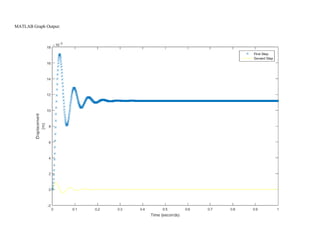

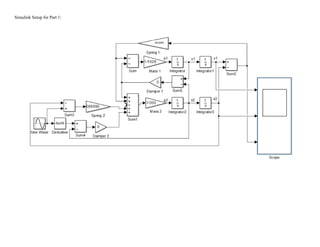

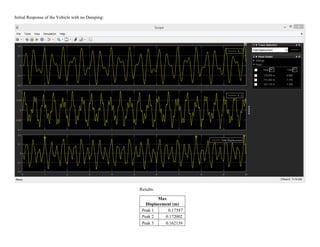

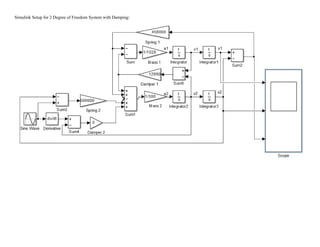

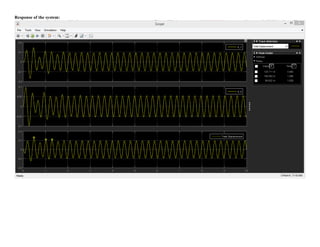

This document summarizes simulations of a mass-spring-damper system representing a bus. Simulation 1 examines the system's response to step inputs without and with increased force. Adding damping is found to significantly reduce displacement peaks. Simulation 2 models a 2-degree-of-freedom system for a bus traveling on a bumpy road. Initially, large displacement peaks occur. By adding damping with a ratio of 0.3, displacements are reduced by 30-40% and the system quickly compensates to match the road input.