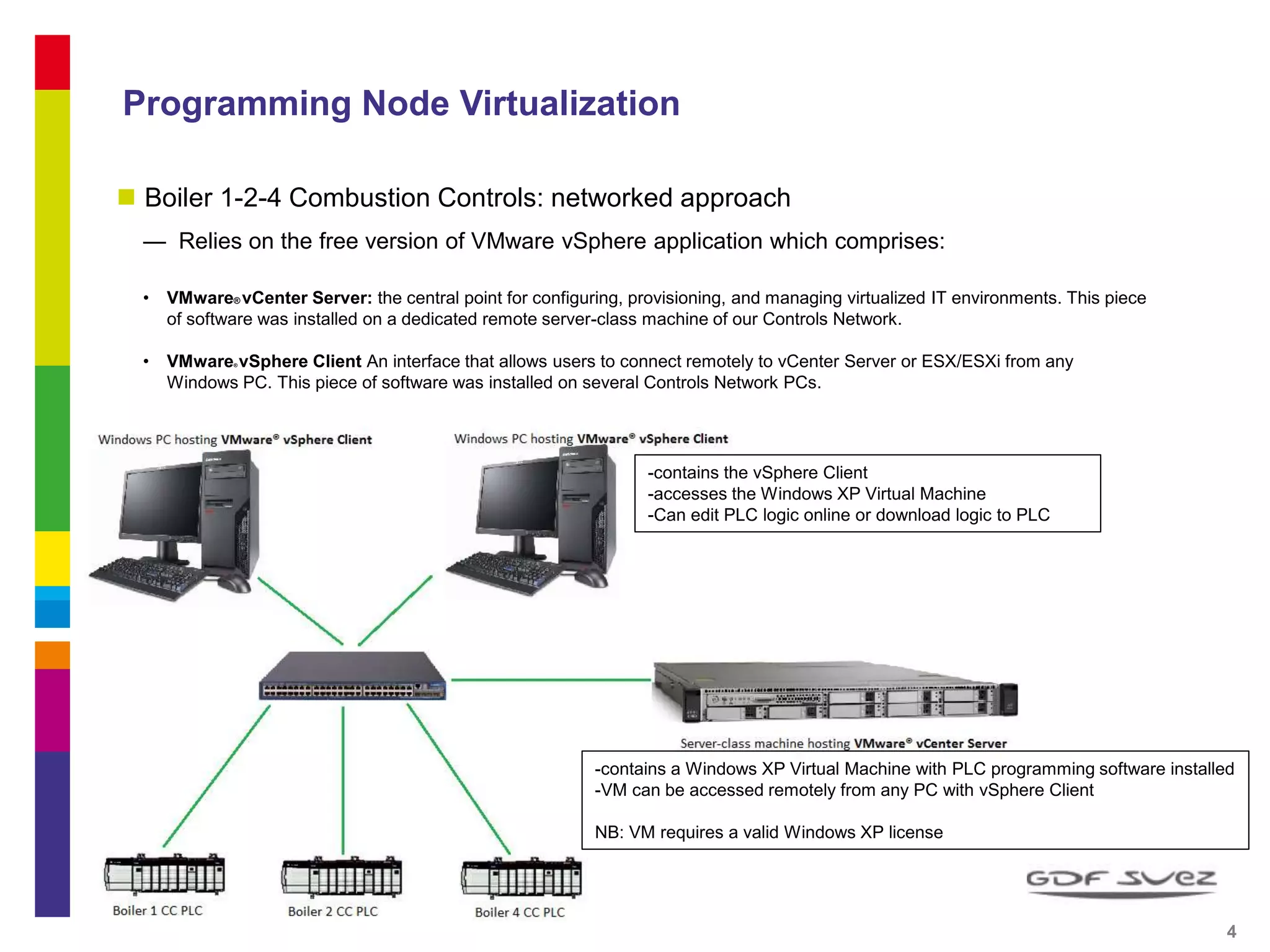

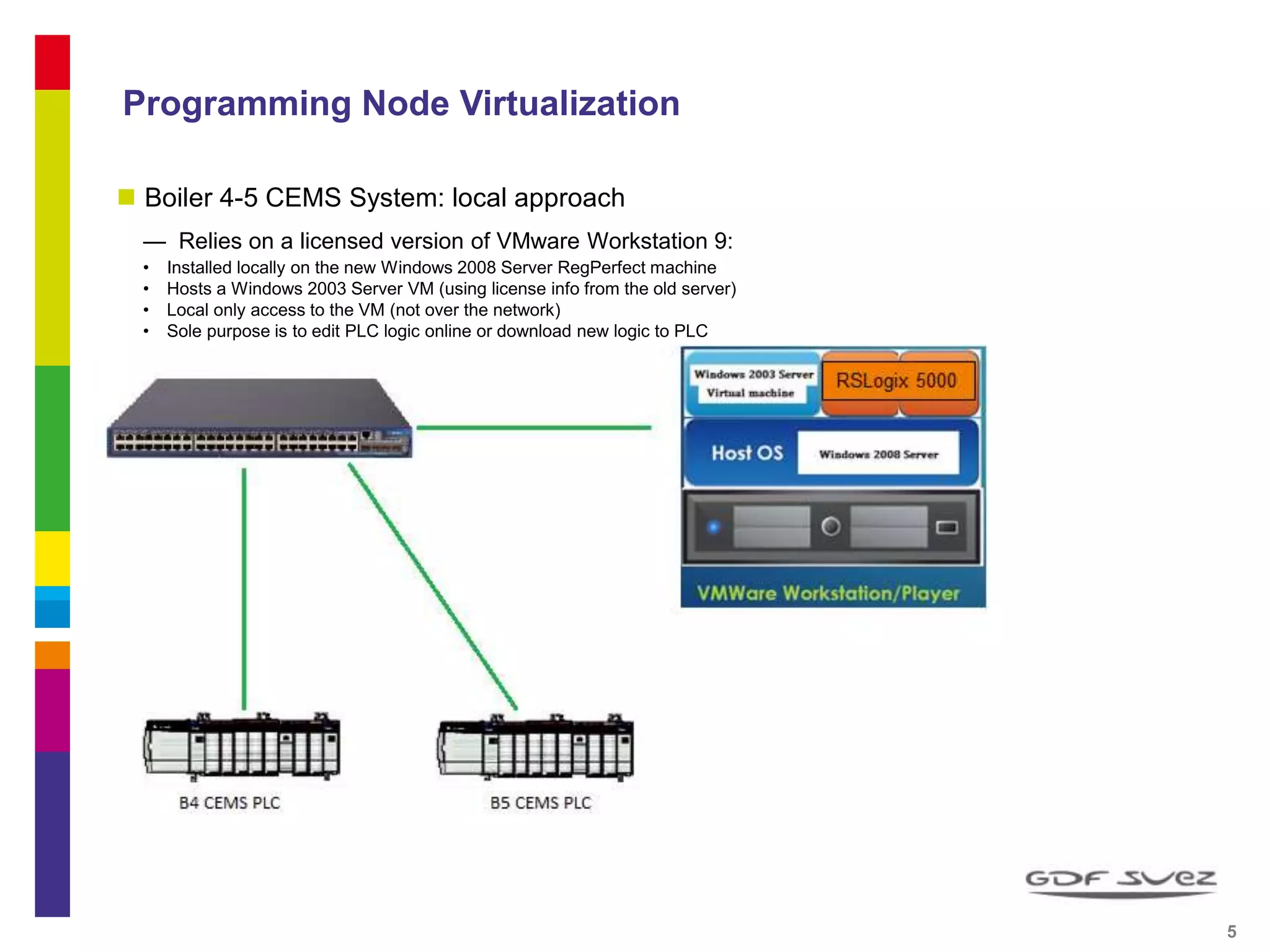

Legacy controls systems face obsolescence issues as their underlying hardware and software ages. At a power plant, two control systems experienced this when their programming nodes - aging PCs running obsolete operating systems - were at risk of failure. Virtualizing the programming nodes solved this by hosting the legacy software in virtual machines, extending the life of the control systems cost effectively. This approach could help virtualize entire legacy SCADA systems for advantages like easy migration and hardware redundancy.