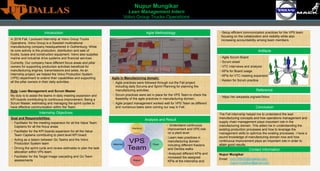

Nupur Mungikar completed an internship at Volvo Group Trucks Operations in 2016. As a Lean Management Intern, she helped the Volvo Production System department extend their capabilities by assisting teams with daily meetings and KPI boards. As a Scrum Master, she estimated and managed sprint cycles to facilitate effective communication within the team. The internship helped her understand lean manufacturing concepts and how operations management supports the manufacturing process through continuous improvement.