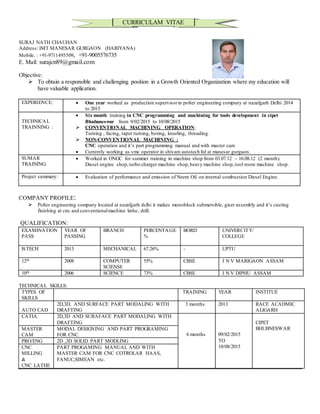

Suraj Nath Chauhan is seeking a responsible position in a growth-oriented organization. He has over 1 year of experience as a production supervisor and is currently working as a VMC operator at Shivam Autotech Ltd. in Manesar, Gurgaon. He has a B.Tech in Mechanical Engineering from UPTU and received 6 months of CNC programming and machining training from CIPET Bhubaneswar. His technical skills include CAD, CAM, and operating CNC milling and lathe machines.