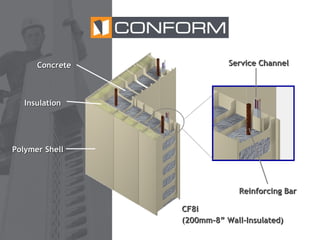

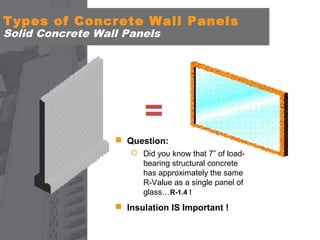

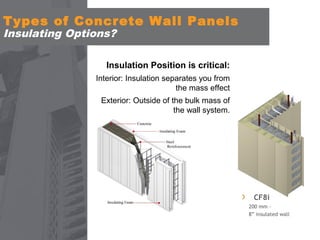

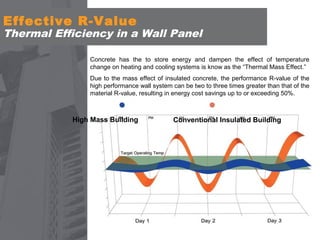

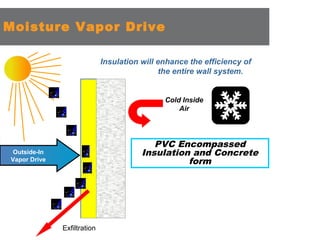

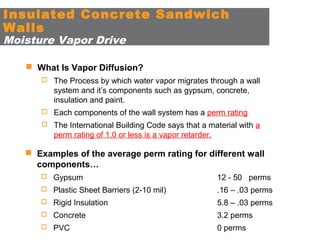

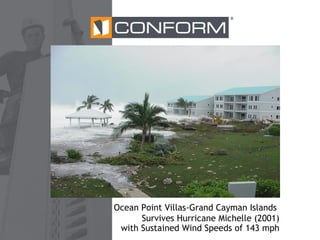

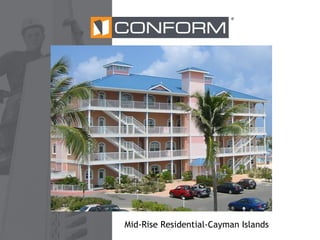

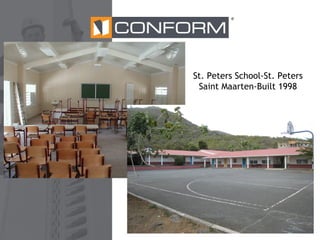

This document introduces Nuform Building Technologies' CONFORM insulated concrete form system. CONFORM allows builders to construct durable, energy efficient concrete walls that are corrosion resistant and require minimal maintenance. The precut forms interconnect on site for quick assembly. CONFORM walls can be solid concrete or insulated. Insulated walls provide better thermal efficiency and moisture protection than traditional construction. Various commercial and residential projects around the world have used CONFORM to withstand hurricanes and tropical conditions.