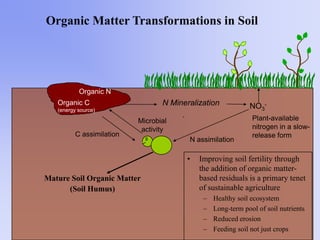

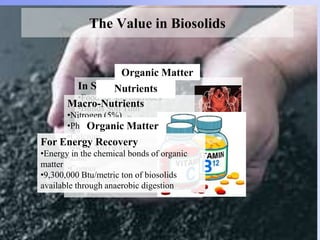

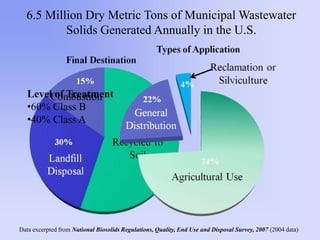

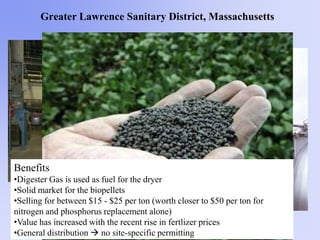

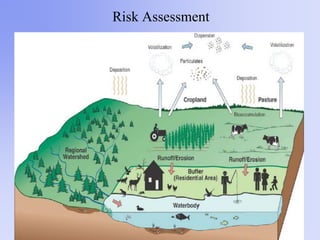

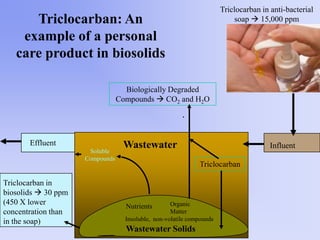

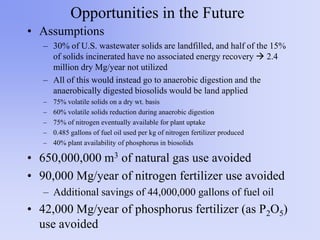

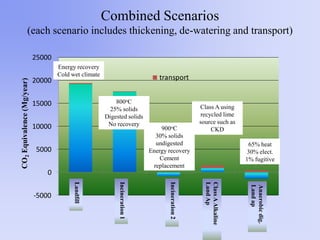

The document discusses the potential for maximizing resource recovery from biosolids, emphasizing the importance of organic matter in improving soil fertility and supporting sustainable agriculture. It details the benefits of anaerobic digestion for energy recovery, potential savings in fertilizer use, and trends in wastewater solids management in the U.S. The document concludes by identifying future opportunities for biosolids utilization, suggesting that increased recycling through digestion can lead to significant environmental and economic benefits.