ni ti and martensitic transformation.pptx

- 3. . . Ts . . . Tf . Stable Austenite (L) Unstable Austenite T Log t Annealing T E (melting temp) start finish Pearlite (Fe3C) Quenching M s M f Martensite A + P A + M Time Temperature Transformation (TTT) start finish Atomic mobility decrease Transformation driving force increase Because no atomic migration is necessary, the transformations usually progress in a time-independent fashion, with the speed of the interface between the two phases able to move at nearly the speed of sound. This type of transformation is referred to as an Athermal transformation since it cannot progress at a constant temperature, but rather the amount of the new phase present depends only upon temperature, not time

- 11. Schematic illustration of parent and martensite with invariant plane as a habit plane.

- 15. Super elasticity, or Pseudo elasticity, can be defined as the ability of certain materials to recover their original shape after the load is removed even when they are deformed beyond their yield strength. The driving force for the reverse-transformation is the difference between the chemical free energy of the parent and martensitic phases above As, and the complete shape recovery lies in that the original orientation of the parent phase can be restored (crystallographic reversibility). In most metals, when an external force exceeds a given amount mechanical slip is induced within the lattice causing permanent deformation; however, with NiTi alloys a stress-induced martensitic transformation occurs, rather than slip. This effect is called Stress‐Induced Martensite (SIM) transformation.

- 16. Super elasticity When the stress stops without permanent deformation occurring returning to the previous shape with a return to the austenite phase, provided the temperature is within a specific range austenite is transformed to martensite by stress; for a practical example, an insertion of the instrument into a curved root canal. Because the stress‐induced martensitic state is not stable at the intraoral temperature, unloading of the endodontic instrument (e.g., withdrawal of an instrument out of a curved root canal) leads to reverse transformation back to the austenite phase resulting in a spring‐back of the endodontic instrument to its original shape

- 18. Shape memory effect Shape-Memory Effect (SME), which is the ability of the alloy to completely recover its original shape when heated above the martensite-to-austenite transformation temperature The transformation induced in the alloy occurs by a shear type of process to a phase called the martensitic or daughter phase ,which gives rise to twinned martensite The deformation can be reversed by heating the alloy above the As with the result that the properties of the NiTi alloy revert back to their previous higher temperature values

- 19. Martensite’s crystal structure has the unique ability to undergo limited deformation in some ways without breaking atomic bonds, known as the twinning, which consists of the rearrangement of atomic planes without causing slip or permanent deformation allowing to undergo about 6–8% strain in this manner. When martensite is reverted to austenite by heating, the original austenitic structure is restored, regardless of whether the martensite phase was deformed; hence, the name “shape memory” refers to the fact that the shape of the high- temperature austenite phase is “remembered,” even though the alloy is severely deformed at a lower temperature.

- 20. Different phases of shape memory alloy at different temperature and their relationship with loading and unloading Superelasticity = mechanical (Stress Induced Martensite) Shape memory = thermal + mechanical stress (Thermal Induced Martensite)

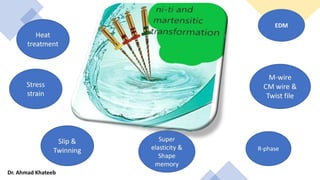

- 21. The differences between NiTi alloys are their nickel content and their temperature ranges of MT.

- 23. The "premartensitic transition" precedes the martensitic transformation under certain conditions. R-phase possesses a lower shear modulus than martensite and austenite, and the transformation strain for R-phase is less than one-tenth that of martensitic transformation. The two step transformations of : (B2 Austenite → R-phase) -- and subsequent --- (R-phase → B19′ Martensite) ,, occurs upon cooling when : Rs (the start temperature of As → R-phase transition) is below Ms (start temperature of martensite transformation) A variety of possible Martensite variants are obtained by using different twinned R-phase as matrix and by changing the rhombohedral angle.

- 24. The R-phase transition usually appears prior to the martensitic transformation when Ms is more lowered by some means. There are many factors effective to depress the Ms point as follows: (1) Increasing Ni-content. (2) Aging after solution-treatment (3) Annealing at a low temperature immediately after cold work. (4) Thermal cycling. (5) Substitution of a third element

- 26. Ti Ni BCC Body centered cubic The crystal structures of Ni-Ti Left: Austenite, which is ordered Face-centered cubic; Middle: R-phase, which is rhomboidal Right: Martensite, which is Body-centered cubic

- 27. Transformation temperatures are highly dependent on the nickel concentration of the alloy. On the Ni-rich side, increasing nickel content results in a drastic decrease in transformation temperature. On the Ni-rich side, Ti3Ni4 precipitates can be formed from TiNi3 decomposition. These precipitates (TiNi3) can affect the characteristics of martensitic transformation and act as nucleation centers for formation of the R phase For NiTi alloys in which SME(shape memory effect) is desired, the Ni content limits range from 48% to 52% Ni by weight

- 28. The heat treatments performed in NiTi alloys with the aim of improving their properties are: Aging :process consists of uniform heating of the alloy to about 500°C followed by rapid cooling (quenching), usuall in water, to temporarily prevent precipitation of the alloying elements. the aging time is an important factor affecting the Ms temperature and consequently affecting the transformation sequence of Ti49Ni51 which is aged at 400°C, × 1 h. Annealing :Is when The material is heated to 300–500°C until the desired changes have taken place over the entire mass of the part, which is then cooled slowly. Recrystallization :is the replacement of a cold-deformed structure by a new set of deformation-free grains, as eviden reduction in hardness and an increase in ductility. To eliminate the hardening effect caused by cold forming, annealing is performed to achieve recrystallization.

- 30. Twisted File

- 31. In the case of TF, maintaining the NiTi alloy in R-phase by heat treatment enables the twisting process. Thus, it is easier to apply plastic deformation to R-phase because lower stress would be required. According to the manufacturer, TF instruments are developed by: 1- Transforming a raw NiTi wire in the austenite to R-phase through a thermal process. 2- In the R-phase, the NiTi blank is twisted along with repeated heat treatment, and after additional thermal procedures to maintain its new shape. 3- The instrument is converted back to austenite, which is super-elastic once stressed. Attempts to twist instruments in the conventional way would probably result in instrument fracture. R-phase possesses lower shear modulus than martensite and austenite, and the transformation strain for R-phase transformation is less than one-tenth that of martensitic transformation.

- 32. The manufacturer claims that this proprietary twisting process with concurrent heat treatment and protection of the crystalline structure imparts superior flexibility and resistance to fatigue. TF instruments are significantly more resistant to cyclic fatigue than ground ones. The twisting process avoids machining defects The higher Ms temperature of TF may require the lower critical stress to induce martensitic transformation

- 33. CM Wire

- 34. CM NiTi files do not present the rebound effect after unloading, and their original shape is restored only after autoclaving. The behavior of these files may be explained by the presence of stable martensite, meaning that the working temperature is below the Af. Stable martensite is known for exhibiting the shape memory effect, which is the capacity to recover the original shape by reverse transformation after heating the deformed martensite to temperatures above the Af These temperatures are strictly related to the nickel content of the alloy and/or its thermomechanical history, which is unknown for the CM NiTi wires. The G-wire was developed in 2015, which is manufactured through several processes; (1) by producing a mixed phase of austenitic phase, R-phase, and martensitic phase by M-wire treatment, (2) by precipitating Ti3Ni4 in the austenitic phase, (3) By controlling excessive growth of martensitic phase to promote the formation of R-phase HyFlex (HF) is produced using CM wire to possess martensitic property at room temperature, resulting in no spring back and excellent root canal trackability.

- 35. CM wire was a kind of Ni-rich NiTi alloy that possessed a relatively high As and Af compared with regular SE wire. At room temperature the instrument may be a composite of R-phase martensite and austenite, unlike conventional NiTi instruments, which are purely austenitic. CM instruments have >300% greater resistance to cyclic fatigue when compared to SE instruments The transformation temperatures increase as the nickel content decreases. Thus, with the decrease of the nickel content in the NiTi alloy, the Af increases as well as the tendency to obtain stable martensite at the working temperature. Furthermore, Zinelis et al showed that Hyflex CM files have a lower percentage of nickel (52.1 %wt) than do conventional NiTi files.

- 36. M - wire

- 37. The austenite-finish temperature of M-Wire (45°C – 50°C) is much higher than that for conventional superelastic wire (approximately 20°C or lower) At room temperature GTP®Series X™ instruments made from M-Wire exist in the martensite phase. This martensite phase results from extensive thermomechanical processing that occurs during the manufacture of the starting M-Wire segments. The special martensite structure accounts for the superior mechanical properties of M-Wire instruments. M-Wire instruments are largely a mixture of martensite and R-phase at room temperature, with a small amount of austenite. EDS analysis indicate that the approximate composition of the precipitates in the M-Wire microstructure is TiB2BNi, which indicates that the starting wire segments are Ti-rich rather than Ni-rich.

- 38. M-Wire instruments have significantly higher hardness compared with conventional rotary NiTi instruments The increased hardness of the M-Wire instruments is attributed to the special work-hardened martensite structure found by STEM examination of starting wire blanks and metallographic examination of the etched microstructures of instruments. M-Wire has relatively coarse grains, numerous triple-point junctions of grain boundaries, and localized deformation bands with microtwins, indicative of extensive thermomechanical processing.

- 39. Hyflex EDM