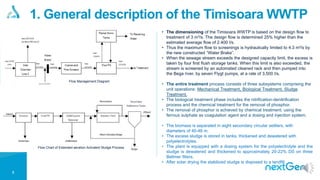

The document discusses plans to implement next generation solutions at the Timisoara WWTP in Romania. The WWTP currently treats an average daily flow of 2,400 liters per second. The solutions aim to:

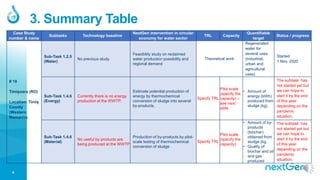

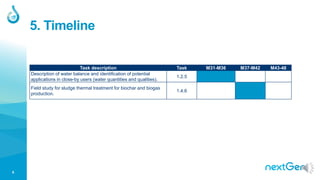

1) Conduct a feasibility study on reusing effluent water from the WWTP for urban, industrial, and agricultural applications in the Timisoara region.

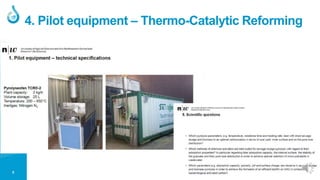

2) Estimate the potential energy production from thermochemical conversion of sludge into byproducts like biochar, oil, and gas using a pilot-scale system.

3) Test the thermochemical conversion of sludge to produce useful byproducts like biochar on a pilot scale.