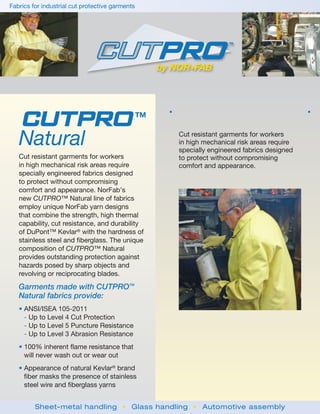

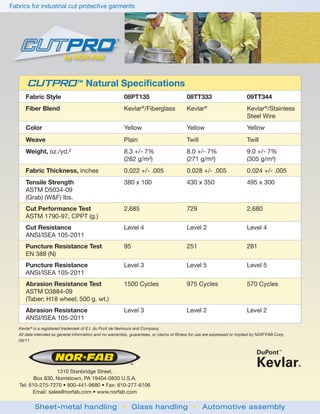

The document describes fabrics made by NorFab called CUTPRO Natural that are designed for cut protection in industrial work environments. The fabrics combine Kevlar with stainless steel and fiberglass to provide strength, thermal capability, cut resistance, durability, and protection against sharp objects. Garments made from CUTPRO Natural fabrics can provide up to level 4 cut protection, level 5 puncture resistance, and level 3 abrasion resistance. The fabrics have inherent flame resistance and the appearance of natural Kevlar to mask the presence of stainless steel and fiberglass yarns.