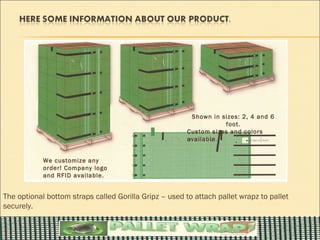

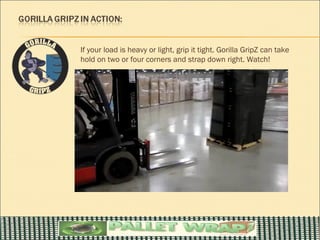

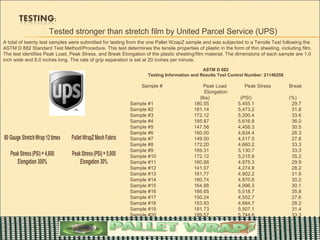

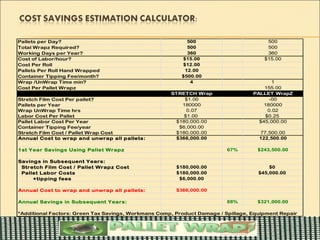

Brandi Priest is presenting on Pallet Wrapz, a reusable mesh wrap for securing pallets that provides several benefits over traditional plastic stretch wrap. It can reduce warehouse accidents, save time and money compared to stretch wrap, and is a more sustainable "green" product. Pallet Wrapz is made of durable, weather-resistant mesh and fastens securely around pallets using straps. It is reusable, recyclable, and provides ventilation to reduce spoilage.