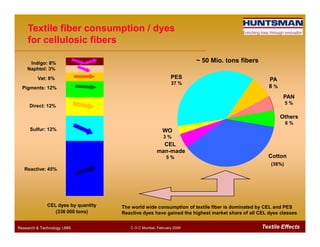

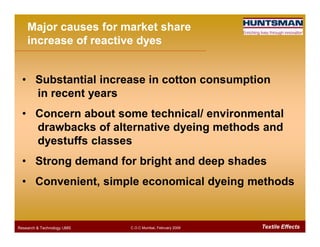

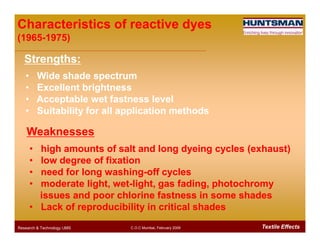

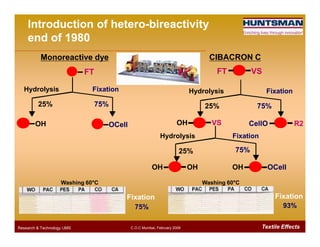

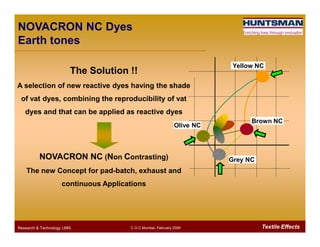

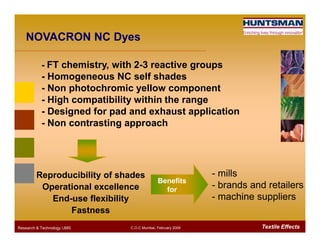

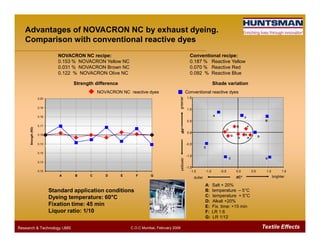

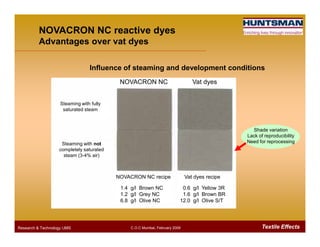

This document discusses reactive dyes, specifically NOVACRON NC reactive dyes. It notes that reactive dyes have gained the highest market share of cellulosic dyes due to advantages like bright shades, simple dyeing methods, and wide color ranges. NOVACRON NC dyes were developed to provide the reproducibility of vat dyes while being applied like reactive dyes. They have non-contrasting properties that make the shades less sensitive to dyeing parameters and fluctuations, improving reproducibility. The dyes were designed for earth tones commonly used in apparel and home textiles.