This document is the 2005 edition of NFPA 70, the National Electrical Code (NEC). It provides the requirements for electrical installations in the United States, including wiring, overcurrent protection, grounding, and equipment specifications. The NEC is developed through a consensus process by the NFPA and is revised on a three-year cycle. This edition supersedes all previous editions and marks the 50th edition of the NEC. Changes from the previous edition are indicated by rules in the margin.

![NATIONAL ELECTRICAL CODE COMMITTEE

NATIONAL ELECTRICAL CODE COMMITTEE

These lists represent the membership at the time the Committee was balloted on the final text of this edition. Since

that time, changes in the membership may have occurred. A key to classifications is found at the back of this

document.

Technical Correlating Committee

James W. Carpenter, Chair

International Association of Electrical Inspectors, TX [E]

Rep. International Association of Electrical Inspectors

Mark W. Earley, Secretary

NFPA, MA

(nonvoting)

Jean A. O’Connor, Recording Secretary

NFPA, MA

(nonvoting)

James E. Brunssen, Telcordia, NJ [UT] James M. Daly, General Cable, NJ [M]

Rep. Alliance for Telecommunications Industry Solutions Rep. National Electrical Manufacturers Association

Michael I. Callanan, National Joint Apprentice & Training (Alt. to J. T. Pauley)

Committee, MD [L] Stanley J. Folz, Folz Electric, Incorporated, IL [IM]

Rep. International Brotherhood of Electrical Workers Rep. National Electrical Contractors Association

William R. Drake, Marinco, CA [M] (Alt. to M. D. Toman)

John R. Kovacik, Underwriters Laboratories Incorporated, Palmer L. Hickman, National Joint Apprentice & Training

IL [RT] Committee, MD [L]

James T. Pauley, Square D Company, KY [M] Rep. International Brotherhood of Electrical Workers

Rep. National Electrical Manufacturers Association (Alt. to M. I. Callanan)

Michael D. Toman, MEGA Power Electrical Services, Neil F. LaBrake, Jr., Niagara Mohawk, a National Grid

Incorporated, MD [IM]

Company, NY [UT]

Rep. National Electrical Contractors Association

Rep. Electric Light & Power Group/EEI

John W. Troglia, Edison Electric Institute, WI [UT]

Rep. Electric Light & Power Group/EEI (Alt. to J. W. Troglia)

Craig M. Wellman, DuPont Engineering, DE [U] William M. Lewis, Eli Lilly & Company, IN [U]

Rep. American Chemistry Council Rep. American Chemistry Council

(Alt. to C. M. Wellman)

Alternates Mark C. Ode, Underwriters Laboratories Incorporated,

Jeffrey Boksiner, Telcordia Technologies, Incorporated, NC [RT]

NJ [UT] (Alt. to J. R. Kovacik)

Rep. Alliance for Telecommunications Industry Solutions Nonvoting

(Alt. to J. E. Brunssen)

Philip H. Cox, Bigelow, AR [E] Richard G. Biermann, Biermann Electric Company,

Rep. International Association of Electrical Inspectors Incorporated, IA [IM]

(Alt. to J. W. Carpenter) D. Harold Ware, Libra Electric Company, OK [IM]

CODE–MAKING PANEL NO. 1

Articles 90, 100, 110, Annex A, Annex G

John D. Minick, Chair

National Electrical Manufacturers Association, TX [M]

Rep. National Electrical Manufacturers Association

Michael A. Anthony, University of Michigan, MI [U] H. Landis Floyd II, The DuPont Company, DE [U]

Rep. The Association of Higher Education Facilities Rep. Institute of Electrical & Electronics Engineers,

Officers Incorporated

Louis A. Barrios, Jr., Shell Global Solutions, TX [U] Palmer L. Hickman, National Joint Apprentice & Training

Rep. American Chemistry Council Committee, MD [L]

David A. Dini, Underwriters Laboratories Incorporated, Rep. International Brotherhood of Electrical Workers

IL [RT] David L. Hittinger, IEC of Greater Cincinnati, OH [IM]

William T. Fiske, Intertek Testing Services NA, Rep. Independent Electrical Contractors, Incorporated

Incorporated, NY [RT]

2005 Edition NATIONAL ELECTRICAL CODE 70–9](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-12-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

Randall R. McCarver, Telcordia Technologies, Incorporated, Neil F. LaBrake, Jr., Niagara Mohawk, a National Grid

NJ [U] Company, NY [UT]

Rep. Alliance for Telecommunications Industry Solutions Rep. Electric Light & Power Group/EEI

Lanny G. McMahill, City of Phoenix, AZ [E] (Alt. to J. W. Troglia)

Rep. International Association of Electrical Inspectors Donald H. McCullough, II, Westinghouse Savannah River

H. Brooke Stauffer, National Electrical Contractors Company, SC [U]

Association, MD [IM] Rep. Institute of Electrical & Electronics Engineers,

Rep. National Electrical Contractors Association Incorporated

John W. Troglia, Edison Electric Institute, WI [UT] (Alt. to H. L. Floyd II)

Rep. Electric Light & Power Group/EEI

Gil Moniz, National Electrical Manufacturers Association,

Alternates MA [M]

Rep. National Electrical Manufacturers

Lawrence S. Ayer, Biz Com Electric, Incorporated, OH [IM]

Association

Rep. Independent Electrical Contractors, Incorporated

(Alt. to J. D. Minick)

(Alt. to D. L. Hittinger)

Kenneth P. Boyce, Underwriters Laboratories Incorporated, Rick Munch, Frischhertz Electric Company, LA [L]

IL [RT] Rep. International Brotherhood of Electrical

(Alt. to D. A. Dini) Workers

Ernest J. Gallo, Telcordia Technologies, Incorporated, NJ [U] (Alt. to P. L. Hickman)

Rep. Alliance for Telecommunications Industry Solutions

(Alt. to R. R. McCarver)

Russell J. Helmick, Jr., City of Irvine, CA [E]

Nonvoting

Rep. International Association of Electrical Inspectors Ark Tsisserev, City of Vancouver, BC, Canada

(Alt. to L. G. McMahill) Rep. Canadian Standards Association International

CODE–MAKING PANEL NO. 2

Articles 210, 215, 220, Annex D, Examples 1 through 6

Raymond W. Weber, Chair

State of Wisconsin, WI [E]

Rep. International Association of Electrical Inspectors

Richard W. Becker, Engineered Electrical Systems, Ernest S. Broome, City of Knoxville, TN [E]

Incorporated, WA [U] Rep. International Association of Electrical Inspectors

Rep. Institute of Electrical & Electronics Engineers, (Alt. to R. W. Weber)

Incorporated James R. Jones, University of Alabama at Birmingham, AL

Frank Coluccio, New York City Department of Buildings, [U]

NY [E] Rep. Institute of Electrical & Electronics Engineers,

Matthew D. Dobson, National Association of Home Incorporated

Builders, DC [U] (Alt. to R. W. Becker)

Rep. National Association of Home Builders Daniel J. Kissane, Pass & Seymour/Legrand, NY [M]

Thomas L. Harman, University of Houston/Clear Lake, TX

Rep. National Electrical Manufacturers Association

[SE]

(Alt. to J. T. Pauley)

Donald M. King, IBEW Local Union 313, DE [L]

Rep. International Brotherhood of Electrical Workers Brian J. Nenninger, The Dow Chemical Company, TX [U]

Christopher P. O’Neil, National Grid USA Service Rep. American Chemistry Council

Company, MA (Alt. to J. P. Roché)

Rep. Electric Light & Power Group/EEI, MA Clifford L. Rediger, Independent Electrical Contractors

James T. Pauley, Square D Company, KY [M] Training Fund, CO [IM]

Rep. National Electrical Manufacturers Association Rep. Independent Electrical Contractors, Incorporated

Susan W. Porter, Underwriters Laboratories Incorporated, (Alt. to R. G. Wilkinson)

NY [RT] Richard V. Wagner, Underwriters Laboratories Incorporated,

Joseph Patterson Roché, Celanese Acetate, SC [U] NY [RT]

Rep. American Chemistry Council (Alt. to S. W. Porter)

Albert F. Sidhom, U.S. Army Corps of Engineers, CA [U] Joseph E. Wiehagen, National Association of Home

Michael D. Toman, MEGA Power Electrical Services, Builders, MD [U]

Incorporated, MD [IM] Rep. National Association of Home Builders

Rep. National Electrical Contractors Association (Alt. to M. D. Dobson)

Robert G. Wilkinson, Independent Electrical Contractors of

Texas Gulf Coast, TX [IM] Nonvoting

Rep. Independent Electrical Contractors, Incorporated

Douglas A. Lee, U.S. Consumer Product Safety

Alternates Commission, MD [C]

Kevin J. Brooks, IBEW Local Union 16, IN [L] Andrew M. Trotta, U.S. Consumer Product Safety

Rep. International Brotherhood of Electrical Workers Commission, MD [C]

(Alt. to D. M King) (Alt. to D. A. Lee)

70–10 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-13-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

CODE–MAKING PANEL NO. 3

Articles 300, 590, 720, 725, 727, 760, Chapter 9, Tables 11(a) and (b), and Tables 12(a) and (b)

Richard P. Owen, Chair

City of St. Paul, MN [E]

Rep. International Association of Electrical Inspectors

Lawrence S. Ayer, Biz Com Electric, Incorporated, OH [IM] Adam D. Corbin, Corbin Electrical Services, Incorporated,

Rep. Independent Electrical Contractors, Incorporated NJ [IM]

Paul J. Casparro, Scranton Electricians JATC, PA [L] Rep. Independent Electrical Contractors, Inc.

Rep. International Brotherhood of Electrical Workers (Alt. to L. S. Ayer)

Les Easter, Allied Tube and Conduit, IL [M] John C. Hudak, Old Forge, PA [E]

Rep. National Electrical Manufacturers Association Rep. International Association of Electrical Inspectors

Sanford E. Egesdal, Egesdal Associates PLC, MN [M] (Alt. to R. P. Owen)

Rep. Automatic Fire Alarm Association, Incorporated Danny Liggett, DuPont Engineering, DE [U]

Thomas J. Guida, Underwriters Laboratories, Inc., NY [RT] Rep. American Chemistry Council

Dennis B. Horman, PacifiCorp, UT [UT] (Alt. to D. A. Pace)

Rep. Electric Light & Power Group/EEI Juan C. Menendez, Southern California Edison Company,

Ray R. Keden, ERICO, Incorporated, CA [M] CA [UT]

Rep. Building Industry Consulting Services International Rep. Electric Light & Power Group/EEI

Ronald E. Maassen, Lemberg Electric Company,

(Alt. to D. B. Horman)

Incorporated, WI [IM]

T. David Mills, Bechtel Savannah River, Incorporated,

Rep. National Electrical Contractors Association

SC [U]

Steven J. Owen, Steven J. Owen, Incorporated, AL [IM]

Rep. Associated Builders and Contractors, Incorporated Rep. Institute of Electrical & Electronics Engineers,

David A. Pace, Olin Corporation, AL [U] Incorporated

Rep. American Chemistry Council (Alt. to M. K. Sanders)

Melvin K. Sanders, Things Electrical Company, Mark C. Ode, Underwriters Laboratories Incorporated,

Incorporated (TECo., Incorporated), IA [U] NC [RT]

Rep. Institute of Electrical & Electronics Engineers, (Alt. to T. J. Guida)

Incorporated Lorena Orbanic, Carlon, Lamson & Sessions, OH [M]

John E. Sleights, Travelers Insurance, CT [I] Rep. Building Industry Consulting Services International

(Alt. to R. R. Keden)

Alternates Roger S. Passmore, Davis Electrical Constructors,

Mark E Christian, Chattanooga Electrical JATC, TN [L] Incorporated, SC [IM]

Rep. International Brotherhood of Electrical Workers Rep. Associated Builders and Contractors, Incorporated

(Alt. to P. J. Casparro) (Alt. to S. J. Owen)

Dr. Shane M. Clary, Bay Alarm Company, Incorporated, George A. Straniero, AFC Cable Systems, Incorporated,

CA [M] NJ [M]

Rep. Automatic Fire Alarm Association, Incorporated Rep. National Electrical Manufacturers Association

(Alt. to S. E. Egesdal) (Alt. to L. Easter)

CODE–MAKING PANEL NO. 4

Articles 225, 230

James M. Naughton, Chair

IBEW Local Union 103, MA [L]

Rep. International Brotherhood of Electrical Workers

Malcolm Allison, Ferraz Shawmut, MA [M] John W. Young, Siemens Energy & Automation,

C. John Beck, Pacific Gas and Electric Company, Incorporated, GA [M]

CA [UT] Rep. National Electrical Manufacturers Association

Rep. Electric Light & Power Group/EEI Vincent Zinnante, Advantage Electric, Incorporated,

Robert J. Deaton, The Dow Chemical Company, TX [U] TX [IM]

Rep. Institute of Electrical & Electronics Engineers, Rep. Independent Electrical Contractors, Incorporated

Incorporated

Howard D. Hughes, Hughes Electric Company Alternates

Incorporated, AR [IM] Thomas L. Adams, Exelon Corporation, IL [UT]

Rep. National Electrical Contractors Association Rep. Electric Light & Power Group/EEI

William M. Lewis, Eli Lilly & Company, IN [U] (Alt. to C. J. Beck)

Rep. American Chemistry Council Ronald Breschini, Underwriters Laboratories Incorporated,

Mark C. Ode, Underwriters Laboratories Incorporated, CA [RT]

NC [RT] (Alt. to M. C. Ode)

James J. Rogers, Towns of Oak Bluffs, Tisbury, West Terry D. Cole, Hamer Electric, WA [IM]

Tisbury, MA [E] Rep. Independent Electrical Contractors, Incorporated

Rep. International Association of Electrical Inspectors (Alt. to V. Zinnante)

2005 Edition NATIONAL ELECTRICAL CODE 70–11](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-14-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

Mark R. Hilbert, State of New Hampshire, NH [E] John Sigmund, PPG Industries, Incorporated,

Rep. International Association of Electrical Inspectors LA [U]

(Alt. to J. J. Rogers) Rep. American Chemistry Council

Philip M. Piqueira, General Electric Company, CT [M] (Alt. to W. M. Lewis)

Rep. National Electrical Manufacturers Association

Mark H. Sumrall, IBEW Local Union 527, TX [L]

(Alt. to J. W. Young)

Francis E. Rose, Jr., W. S. Nelson and Company, Rep. International Brotherhood of Electrical

Workers

Incorporated, LA [U]

Rep. Institute of Electrical & Electronics Engineers, (Alt. to J. M. Naughton)

Incorporated Kent Walker, Ferraz Shawmut, MA [M]

(Alt. to R. J. Deaton) (Alt. to M. Allison)

CODE-MAKING PANEL NO. 5

Articles 200, 250, 280, 285

Ronald J. Toomer, Chair

Toomer Electrical Company Incorporated, LA [IM]

Rep. National Electrical Contractors Association

Jeffrey Boksiner, Telcordia Technologies, Incorporated, Alternates

NJ [UT]

Martin D. Adams, Adams Electric, Incorporated, CO [IM]

Rep. Alliance for Telecommunications Industry

Rep. National Electrical Contractors Association

Solutions

(Alt. to R. J. Toomer)

David T. Brender, Copper Development Association, David A. Dini, Underwriters Laboratories Incorporated, IL

Incorporated, NY [M] [RT]

Rep. Copper Development Association, Incorporated (Alt. to W. Skuggevig)

Martin J. Brett, Jr., Wheatland Tube Company, Timothy Edwards, Alcan Cable Company, GA [M]

NJ [M] Rep. The Aluminum Association

Rep. American Iron and Steel Institute (Alt. to G. L. Hadeen)

Elio L. Checca, U.S. Department of Labor, VA [E] Robert Figlia, New York Board of Fire Underwriters, NY

Paul Dobrowsky, Eastman Kodak Company, NY [U] [E]

Rep. American Chemistry Council Rep. International Association of Electrical Inspectors

Gerald L. Hadeen, Tehachapi, CA [M] (Alt. to M. J. Johnston)

Rep. The Aluminum Association G. Scott Harding, F. B. Harding, Incorporated, MD [IM]

Dan Hammel, IBEW Local Union 704, IA [L] Rep. Independent Electrical Contractors, Incorporated

Rep. International Brotherhood of Electrical Workers (Alt. to T. G. Robertson)

Michael J. Johnston, International Association of Electrical William J. Helfrich, U.S. Department of Labor, PA [E]

Inspectors, TX [E] (Alt. to E. L. Checca)

Rep. International Association of Electrical Inspectors Ronald Lai, FCI Electrical, NH [M]

Charles Mello, Electro-Test, Incorporated, OR [IM] Rep. National Electrical Manufacturers Association

Rep. InterNational Electrical Testing Association (Alt. to G. J. Steinman)

Incorporated Paul J. LeVasseur, Bay City JEATC, MI [L]

Rep. International Brotherhood of Electrical Workers

Elliot Rappaport, Electro Technology Consultants,

Incorporated, FL [U] (Alt. to D. Hammel)

Rep. Institute of Electrical & Electronics Engineers, Richard E. Loyd, R & N Associates, AZ [M]

Incorporated Rep. American Iron and Steel Institute

(Alt. to M. J. Brett, Jr.)

Ted G. Robertson, Robertson Electric, Incorporated,

Daleep C. Mohla, DCM Electrical Consulting Services,

TX [IM]

Incorporated, TX [U]

Rep. Independent Electrical Contractors, Incorporated

Rep. Institute of Electrical & Electronics Engineers,

Walter Skuggevig, Underwriters Laboratories Incorporated, Incorporated

NY [RT] (Alt. to E. Rappaport)

Gregory J. Steinman, Thomas & Betts Corporation, David Peot, Ryobi, SC [M]

TN [M] Rep. Power Tool Institute, Incorporated

Rep. National Electrical Manufacturers Association (Alt. to R. G. Stoll)

Robert G. Stoll, Thomas Associates, Incorporated, J. Philip Simmons, Simmons Electrical Services, WA [M]

OH [M] Rep. Copper Development Association, Incorporated

Rep. Power Tool Institute, Incorporated (Alt. to D. T. Brender)

C. Douglas White, CenterPoint Energy, Incorporated, James S. Simpson, Southern Company Services, AL [UT]

TX [UT] Rep. Electric Light & Power Group/EEI

Rep. Electric Light & Power Group/EEI (Alt. to C. D.White)

70–12 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-15-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

CODE-MAKING PANEL NO. 6

Articles 310, 400, 402, Chapter 9 Tables 5 through 9, Annex B

Stephen J. Thorwegen, Jr., Chair

Fisk Electric Company, TX [IM]

Rep. National Electrical Contractors Association

Robert Edwards, Alcan Aluminum Corporation, ON, James M. Daly, General Cable, NJ [M]

Canada [M] Rep. Copper Development Association, Incorporated

Rep. The Aluminum Association (Alt. to J. S. Zimnoch)

Samuel B. Friedman, BICC General Cable Corporation, Robert L. Huddleston, Jr., Eastman Chemical Company,

RI [M] TN [U]

Rep. National Electrical Manufacturers Association Rep. American Chemistry Council

G. W. “Jerry” Kent, Kent Electric & Plumbing Systems, (Alt. to D. P. Liggett)

TX [IM] Philip T. Laudicini, Underwriters Laboratories Incorporated,

Rep. Independent Electrical Contractors, Incorporated NY [RT]

David G. Komassa, WE Energies, WI [UT] (Alt. to A. D. Wetherell)

Rep. Electric Light & Power Group/EEI Lowell S. Lisker, American Insulated Wire Corporation,

William F. Laidler, South Shore VoTech/IBEW 223, MA [L] RI [M]

Rep. International Brotherhood of Electrical Workers Rep. National Electrical Manufacturers Association

Danny P. Liggett, DuPont Engineering, TX [U] (Alt. to S. B. Friedman)

Rep. American Chemistry Council Paul R. Picard, AFC Cable Systems, Incorporated, MA [M]

L. Bruce McClung, Electrical Safety Consulting Services, Rep. The Aluminum Association

Incorporated, WV [U] (Alt. to R. Edwards)

Rep. Institute of Electrical & Electronics Engineers, Harry J. Sassaman, Forest Electric Corporation, NJ [IM]

Incorporated Rep. National Electrical Contractors Association

Oran P. Post, City of Cuyahoga Falls, OH [E] (Alt. to S. J. Thorwegen, Jr.)

Rep. International Association of Electrical Inspectors John Stacey, City of St. Louis, MO [E]

Austin D. Wetherell, Underwriters Laboratories Rep. International Association of Electrical Inspectors

Incorporated, NY [RT] (Alt. to O. P. Post)

Joseph S. Zimnoch, The Okonite Company, NJ [M] Donald A. Voltz, Mustang Engineering, Incorporated,

Rep. Copper Development Association, Incorporated TX [U]

Rep. Institute of Electrical & Electronics Engineers,

Alternates Incorporated

Peter E. Bowers, Satellite Electric Company, Incorporated, (Alt. to L. B. McClung)

MD [IM] David R. Wellington, Toledo Electrical JATC, OH [L]

Rep. Independent Electrical Contractors, Incorporated Rep. International Brotherhood of Electrical Workers

(Alt. to G. W. Kent) (Alt. to W. F. Laidler)

CODE-MAKING PANEL NO. 7

Articles 320, 322, 324, 326, 328, 330, 332, 334, 336, 338, 340, 382, 394, 396, 398

Gaylen D. Rogers, Chair

State of Utah, UT [E]

Rep. International Association of Electrical Inspectors

James J. Anastasi, Intertek/ETL Semko, NY [RT] Gregory L. Runyon, Eli Lilly and Company, IN [U]

Harry C. Brown, IBEW Local Union 606, FL [L] Rep. American Chemistry Council

Rep. International Brotherhood of Electrical David E. Schumacher, All County Electric Company,

Workers IA [IM]

John J. Cangemi, Underwriters Laboratories Incorporated, Rep. Associated Builders and Contractors, Incorporated

NY [RT] H. R. Stewart, HRS Consulting, TX [U]

James M. Daly, General Cable, NJ [M] Rep. Institute of Electrical & Electronics Engineers,

Rep. National Electrical Manufacturers Association Incorporated

Chris J. Fahrenthold, Encompass Electrical Technologies, George A. Straniero, AFC Cable Systems, Incorporated,

TX [IM] NJ [M]

Rep. Independent Electrical Contractors, Incorporated Rep. Copper Development Association, Incorporated

Richard Temblador, Alflex Corporation, CA [M]

Robert L. Gotham, Rose City Electric Company, Rep. The Aluminum Association

Incorporated, OR [IM]

Rep. National Electrical Contractors Association Alternates

Herman J. Hall, Austin, TX [M] William B. Crist, Houston Stafford Electric Company,

Rep. Society of the Plastics Industry Incorporated TX [IM]

Ronald G. Nickson, National Multi Housing Council, Rep. Independent Electrical Contractors, Incorporated

DC [U] (Alt. to C. J. Fahrenthold)

Rep. National Multi Housing Council James D. Erwin, Celanese, Limited, TX [U]

Bruce W. Nutt, Oncor, TX [UT] Rep. American Chemistry Council

Rep. Electric Light & Power Group/EEI (Alt. to G. L. Runyon)

2005 Edition NATIONAL ELECTRICAL CODE 70–13](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-16-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

James K. Hinrichs, State of Washington, WA [E] John W. “Wes” Ray, Duke Energy Corporation, NC [UT]

Rep. International Association of Electrical Inspectors Rep. Electric Light & Power Group/EEI

(Alt. to G. D. Rogers) (Alt. to B. W. Nutt)

Samuel R. LaDart, City of Memphis, TN [L] David K. Smith, Encore Wire Limited, TX [M]

Rep. International Brotherhood of Electrical Workers Rep. Copper Development Association, Incorporated

(Alt. to H. C. Brown) (Alt. to G. A. Straniero)

C. David Mercier, Southwire Company, GA [M] John Thomas Thompson, ABC Marathon Electrical

Rep. National Electrical Manufacturers Association

Company, Incorporated, AL [IM]

(Alt. to J. M. Daly)

Rep. Associated Builders and Contractors, Incorporated

Dennis A. Nielsen, Lawrence Berkeley National Laboratory,

CA [U] (Alt. to D. E. Schumacher)

Rep. Institute of Electrical & Electronics Engineers, Larry G. Watkins, Alcan Aluminum Corporation, GA [M]

Incorporated Rep. The Aluminum Association

(Alt. to H. R. Stewart) (Alt. to R. Temblador)

Paul A. Orr, Underwriters Laboratories Incorporated, Thomas H. Wood, Cecil B. Wood Incorporated, IL [IM]

NY [RT] Rep. National Electrical Contractors Association

(Alt. to J. J. Cangemi) (Alt. to R. L. Gotham)

CODE-MAKING PANEL NO. 8

Articles 342, 344, 348, 350, 352, 353, 354, 356, 358, 360, 362, 366, 368, 370, 372, 374, 376, 378, 380, 384,

386, 388, 390, 392, Chapter 9 Tables 1 through 4, Annex C

Julian R. Burns, Chair

Burns Electrical/Quality Power Solutions, Incorporated, NC [IM]

Rep. Independent Electrical Contractors, Incorporated

John S. Corry, Corry Electric Incorporated, CA [IM] Charles W. Forsberg, Shaker Heights, OH [M]

Rep. Associated Builders and Contractors, Incorporated Rep. Society of the Plastics Industry Incorporated

Joseph G. Dabe, City of St. Paul, MN [L] (Alt. to D. H. Kendall)

Rep. International Brotherhood of Electrical Workers Dr. Jack A. Gruber, Wheatland Tube Company, PA [M]

George R. Dauberger, Thomas & Betts Corporation, TN [M] Rep. American Iron and Steel Institute

Rep. National Electrical Manufacturers Association (Alt. to R. E. Loyd)

James C. Dollins, AFC Cable Systems, MA [M] James M. Imlah, City of Hillsboro, OR [E]

Rep. The Aluminum Association Rep. International Association of Electrical Inspectors

Ronald E. Duren, PacifiCorp, WA [UT]

(Alt. to W. A. Lilly)

Rep. Electric Light & Power Group/EEI

Alan Manche, Schneider Electric/Square D Company,

M. Shan Griffith, Kelloff, Brown & Root, Incorporated,

TX [U] KY [M]

Rep. Institute of Electrical & Electronics Engineers, Rep. National Electrical Manufacturers Association

Incorporated (Alt. to G. R. Dauberger)

David H. Kendall, Carlon, Lamson & Sessions, OH [M] Jamie McNamara, City of St. Paul, MN [L]

Rep. Society of the Plastics Industry Incorporated Rep. International Brotherhood of Electrical Workers

Wayne A. Lilly, City of Harrisonburg, VA [E] (Alt. to J. G. Dabe)

Rep. International Association of Electrical Inspectors C. Ernest Reynolds, Hatfield-Reynolds Electric Company,

Richard E. Loyd, R & N Associates, AZ [M] AZ [IM]

Rep. American Iron and Steel Institute Rep. Independent Electrical Contractors, Incorporated

Stephen P. Poholski, Newkirk Electric Associates, (Alt. to J. R. Burns)

Incorporated, MI [IM] Richard Temblador, Alflex Corporation, CA [M]

Rep. National Electrical Contractors Association Rep. The Aluminum Association

Dennis L. Rowe, New York Board of Fire Underwriters, (Alt. to J. C. Dollins)

NY [E] Ronald J. Toomer, Toomer Electrical Company

Rep. New York Board of Fire Underwriters Incorporated, LA [IM]

George F. Walbrecht, Underwriters Laboratories Rep. National Electrical Contractors Association

Incorporated, IL [RT]

(Alt. to S. P. Poholski)

Alternates James Van Den Heuvel, West Electric Incorporated,

WI [IM]

Richard Berman, Underwriters Laboratories Incorporated,

Rep. Associated Builders and Contractors, Incorporated

IL [RT]

(Alt. to G. F. Walbrecht) (Alt. to J. S. Corry)

Duane A. Carlson, PRS Consulting Engineers, WA [U] Leslie R. Zielke, South Carolina Electric & Gas Company,

Rep. Institute of Electrical & Electronics Engineers, SC [UT]

Incorporated Rep. Electric Light & Power Group/EEI

(Alt. to M. S. Griffith) (Alt. to R. E. Duren)

70–14 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-17-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

CODE-MAKING PANEL NO. 9

Articles 312, 314, 404, 408, 450, 490

Timothy M. Croushore, Chair

Allegheny Power, PA [UT]

Rep. Electric Light & Power Group/EEI

Jeffery Bernson, IBEW Local Union 701, IL [L] Joseph M. Bolesina, Pinellas County Building Inspections,

Rep. International Brotherhood of Electrical Workers FL [E]

Hector R. de Vega, Fluor Daniel, TX [U] Rep. International Association of Electrical Inspectors

Rep. Associated Builders and Contractors, Incorporated (Alt. to D. R. Offerdahl)

Frederic P. Hartwell, Hartwell Electrical Services, MA [SE] Julian R. Burns, Burns Electrical/Quality Power Solutions,

Robert J. Kaemmerlen, Kaemmerlen Electric Company, Incorporated, NC [IM]

MO [IM] Rep. Independent Electrical Contractors, Incorporated

Rep. National Electrical Contractors Association

(Alt. to T. J. LeMay)

Jacob Killinger, Underwriters Laboratories Incorporated,

IL [RT] James C. Carroll, Square D Company, TN [M]

Thomas J. LeMay, LeMay Electric, Incorporated, GA [IM] Rep. National Electrical Manufacturers Association

Rep. Independent Electrical Contractors, Incorporated (Alt. to B. D. Rupp)

Donald R. Offerdahl, North Dakota State Electrical Board, Richard P. Fogarty, Consolidated Edison Company of NY,

ND [E] Incorporated, NY [UT]

Rep. International Association of Electrical Inspectors Rep. Electric Light & Power Group/EEI

Bradford D. Rupp, Allied Moulded Products, Incorporated, (Alt. to T. M. Croushore)

OH [M] Robert D. Osborne, Underwriters Laboratories Incorporated,

Rep. National Electrical Manufacturers Association NC [RT]

Sukanta Sengupta, FMC Corporation, NJ [U] (Alt. to J. Killinger)

Rep. Institute of Electrical & Electronics Engineers, Jerome W. Seigel, West Hartford, CT [U]

Incorporated Rep. Institute of Electrical & Electronics Engineers,

Ralph H. Young, Eastman Chemical Company, TN [U] Incorporated

Rep. American Chemistry Council

(Alt. to S. Sengupta)

Alternates Monte Szendre, Wilson Construction Company, OR [IM]

Rep. National Electrical Contractors Association

Rodney D. Belisle, NECA-IBEW Training Center, WA [L]

(Alt. to R. J. Kaemmerlen)

Rep. International Brotherhood of Electrical Workers

(Alt. to L. Bernson)

CODE-MAKING PANEL NO. 10

Articles 240, 780

James T. Dollard, Jr., Chair

IBEW Local Union 98, PA [L]

Rep. International Brotherhood of Electrical Workers

Charles K. Blizard, American Electrical Testing Company, John A. Zaplatosch, Underwriters Laboratories

Incorporated, MA [IM] Incorporated, IL [RT]

Rep. InterNational Electrical Testing Association

Incorporated Alternates

Madeline Borthick, IEC of Houston, Incorporated, TX [IM] Robert R. Gage, Niagara Mohawk, A National Grid

Rep. Independent Electrical Contractors, Incorporated Company, NY [UT]

Scott Cline, McMurtrey Electric, Incorporated, CA [IM] Rep. Electric Light & Power Group/EEI

Rep. National Electrical Contractors Association (Alt. to C. K. Eldridge)

Dennis M. Darling, Ayres, Lewis, Norris & May, George D. Gregory, Square D Company, IA [M]

Incorporated, MI [U] Rep. National Electrical Manufacturers Association

Rep. Institute of Electrical & Electronics Engineers, (Alt. to C. W. Kimblin)

Incorporated Roderic L. Hageman, PRIT Service, Incorporated, IL [IM]

Charles K. Eldridge, Indianapolis Power & Light Company, Rep. InterNational Electrical Testing Association

IN [UT] Incorporated

Rep. Electric Light & Power Group/EEI (Alt. to C. K. Blizard)

Carl J. Fredericks, The Dow Chemical Company, TX [U] Charles D. Hughes, Westinghouse Savannah River

Rep. American Chemistry Council Company, SC [U]

C. W. Kimblin, Cutler-Hammer, Incorporated, PA [M] Rep. Institute of Electrical & Electronics Engineers,

Rep. National Electrical Manufacturers Association Incorporated

Arden L. Munson, Hussmann Corporation, MO [M] (Alt. to D. M. Darling)

Rep. Air-Conditioning and Refrigeration Institute Robert J. Kauer, Middle Department Inspection Agency,

George J. Ockuly, Chesterfield, MO [M] Incorporated, PA [E]

Gerald W. Williams, County of Ventura, California, CA [E] Rep. International Association of Electrical Inspectors

Rep. International Association of Electrical Inspectors (Alt. to G. W. Williams)

2005 Edition NATIONAL ELECTRICAL CODE 70–15](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-18-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

Richard E. Lofton, II, IBEW Local Union 280, OR [L] James R. Sicard, Shell Oil Company, TX [U]

Rep. International Brotherhood of Electrical Workers Rep. American Chemistry Council

(Alt. to J. T. Dollard, Jr.) (Alt. to C. J. Fredericks)

Robert W. Mount, Jr., Hussmann Corporation, MO [M] Steve A. Struble, Freeman’s Electric Service, Incorporated,

Rep. Air-Conditioning and Refrigeration Institute SD [IM]

(Alt. to A. L. Munson) Rep. Independent Electrical Contractors, Incorporated

Paul J. Notarian, Underwriters Laboratories Incorporated, (Alt. to M. Borthick)

NY [RT]

(Alt. to J. A. Zaplatosch) Nonvoting

Vincent J. Saporita, Cooper Bussmann, MO [M] Rick C. Gilmour, Canadian Standards Association (CSA),

(Alt. to G. J. Ockuly) ON, Canada

CODE-MAKING PANEL NO. 11

Articles 409, 430, 440, 460, 470, Annex D, Example D8

Wayne Brinkmeyer, Chair

Biddle Electric Corporation, TX [IM]

Rep. National Electrical Contractors Association

Frederick Bried, Spring, TX [U] Ralph M. Esemplare, Consolidated Edison Company of

Rep. American Petroleum Institute New York, NY [UT]

Rick L. Bunch, Tecumseh Products Company, MI [M] Rep. Electric Light & Power Group/EEI

Rep. Air-Conditioning and Refrigeration Institute (Alt. to L. H. Haas, Jr.)

Joe David Cox, Eastman Chemical Company, TN [U] James M. Fahey, IBEW Local Union 103, MA [L]

Rep. American Chemistry Council Rep. International Brotherhood of Electrical Workers

Michael A. D’Amico, IBEW Local Union 488, CT [L] (Alt. to M. A. D’Amico)

Rep. International Brotherhood of Electrical Workers Stanley J. Folz, Folz Electric, Incorporated, IL [IM]

Thomas J. Garvey, State of Wisconsin, WI [E] Rep. National Electrical Contractors Association

Rep. International Association of Electrical Inspectors (Alt. to W. Brinkmeyer)

Charles A. Goetz, Underwriters Laboratories Incorporated, William D. Glover, PPG Industries, Incorporated, WV [U]

IL [RT] Rep. American Chemistry Council

Rep. Associated Builders and Contractors, Incorporated (Alt. to J. D. Cox)

Paul E. Guidry, Fluor Enterprises, Incorporated, TX [U] Paul S. Hamer, ChevronTexaco Corporation, CA [U]

Rep. Associated Builders & Contractors, Incorporated Rep. American Petroleum Institute

Leo H. Haas, Jr., CenterPoint Energy, Incorporated, (Alt. to F. Bried)

TX, [UT] Robert J. Keough, Emerson Motor Company, MO [M]

Rep. Electric Light & Power Group/EEI Rep. National Electrical Manufacturers Association

Vincent J. Saporita, Cooper Bussmann, MO [M] (Alt. to J. R. Wright)

Lynn F. Saunders, General Motors WFG-Utilities Services, Thomas E. Moore, Stark County Building Department,

MI [U] OH [E]

Rep. Institute of Electrical & Electronics Engineers, Rep. International Association of Electrical Inspectors

Incorporated (Alt. to T. J. Garvey)

Lawrence E. Todd, Intertek Testing Services NA, George J. Ockuly, Chesterfield, MO [M]

Incorporated, OR [RT] (Alt. to V. J. Saporita)

Ron Widup, Shermco Industries, Incorporated, TX [IM] Frederic A. Salzman, Underwriters Laboratories

Rep. InterNational Electrical Testing Association Incorporated, IL [RT]

Incorporated (Alt. to C. A. Goetz)

James R. Wright, Siemens Energy & Automation, Arthur J. Smith, III, Waldemar S. Nelson & Company,

Incorporated, IL [M] Incorporated, LA [U]

Rep. National Electrical Manufacturers Association Rep. Institute of Electrical & Electronics Engineers,

Incorporated

Alternates (Alt. to L. F. Saunders)

Elwood J. Dodge, Addison Products Company, FL [M]

Rep. Air-Conditioning and Refrigeration Institute

Nonvoting

(Alt. to R. L. Bunch) Nino Mancini, CSA International, ON, Canada

70–16 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-19-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

CODE-MAKING PANEL NO. 12

Articles 610, 620, 625, 630, 640, 645, 647, 650, 660, 665, 668, 669, 670, 685,

Annex D, Examples D9 and D10

Charles M. Trout, Chair

Maron Electric Company, FL [IM]

Rep. National Electrical Contractors Association

Thomas M. Burke, Underwriters Laboratories Incorporated, James E. Winfrey, Square D Company, NC [M]

CA [RT] Rep. National Electrical Manufacturers Association

Kent B. Givens, Aluminum Company of America, TX [M]

Rep. The Aluminum Association Alternates

(VL to 610, 625, 630, 645, 660, 665, 668, 669, 685) William E. Anderson, The Procter & Gamble Company, OH

Ron L. Janikowski, City of Wausau, Wisconsin, WI [E] [U]

Rep. International Association of Electrical Inspectors Rep. Institute of Electrical & Electronics Engineers,

Robert E. Johnson, ITE Safety, MA [U] Incorporated

Rep. Information Technology Industry Council (Alt. to R. C. Prichard)

(VL to 640, 645, 647, 685) Jeffrey W. Blain, Schindler Elevator Corporation, NJ [M]

Rep. National Elevator Industry Incorporated

Robert A. Jones, Independent Electrical Contractors,

(Alt. to A. Juhasz )

Incorporated, TX [IM]

(VL to 610, 620, 630)

Rep. Independent Electrical Contractors, Incorporated William A. Brunner, IBEW Local Union 714, ND [L]

Andy Juhasz, Kone Incorporated, IL [M] Rep. International Brotherhood of Electrical Workers

Rep. National Elevator Industry Incorporated (Alt. to D. R. Quave)

(VL to 610, 620, 630) Scott Cline, McMurtrey Electric, Incorporated, CA [IM]

Sam Marcovici, New York City Department of Buildings, Rep. National Electrical Contractors Association

NY [E] (Alt. to C. M. Trout)

John H. Mortimer, Inductotherm Corporation, NJ [M] Robert Michael Forister, City of Sheridan, Wyoming,

(VL to 665) WY [E]

Ralph C. Prichard, Hercules Incorporated, DE [U] Rep. International Association of Electrical Inspectors

Rep. Institute of Electrical & Electronics Engineers, (Alt. to R. L. Janikowski)

Incorporated Barry G. Karnes, Underwriters Laboratories Incorporated,

Ronald L. Purvis, Georgia Power Company, GA [UT] CA [RT]

Rep. Electric Light & Power Group/EEI (Alt. to T. M. Burke)

David R. Quave, IBEW Local Union 903, MS [L] Todd F. Lottmann, Cooper Bussmann, MO [M]

Rep. International Brotherhood of Electrical Workers Rep. National Electrical Manufacturers Association

(Alt. to J. E. Winfrey)

Robert H. Reuss, Morris Material Handling, LLC, WI [M]

Roger D. McDaniel, Georgia Power Company, GA [UT]

Rep. Crane Manufacturers Association of America

Rep. Electric Light & Power Group/EEI

Incorporated (Alt. to R. L. Purvis)

(VL to 610) George S. Tidden, George’s Electrical Service Incorporated,

Arthur E. Schlueter, Jr., A. E. Schlueter Pipe Organ TX [IM]

Company, GA [M] Rep. Independent Electrical Contractors, Incorporated

Rep. American Institute of Organ Builders (Alt. to R. A. Jones)

(VL to 640, 650) Robert C. Turner, Inductotherm Corporation, NJ [M]

Kenneth P. White, Olin Corporation, TN [U] (Alt. to J. H. Mortimer)

Rep. American Chemistry Council (VL to 665)

CODE-MAKING PANEL NO. 13

Articles 445, 455, 480, 690, 692, 695, 700, 701, 702, 705

Thomas H. Wood, Chair

Cecil B. Wood Incorporated, IL [IM]

Rep. National Electrical Contractors Association

Tarry L. Baker, Broward County Board of Rules & Ernest J. Gallo, Telcordia Technologies, Incorporated,

Appeals, FL [E] NJ [U]

Rep. International Association of Electrical Inspectors Rep. Alliance for Telecommunications Industry Solutions

Ward I. Bower, Sandia National Laboratories, NM [U] (VL to 445, 480, 690, 692)

Rep. Solar Energy Industries Association Michael V. Glenn, Longview Fibre Company, WA [U]

(VL to 690, 692, 705) Rep. Institute of Electrical & Electronics Engineers,

Douglas L. Elkins, ExxonMobil Chemical Company, Incorporated

TX [U] Banks Hattaway, Hattaway Brothers, Incorporated, AL [IM]

Rep. American Chemistry Council Rep. Associated Builders and Contractors, Incorporated

George W. Flach, George W. Flach Consultant, Timothy D. Holleman, AC Corporation, NC [IM]

Incorporated, LA [SE] Rep. Independent Electrical Contractors, Incorporated

2005 Edition NATIONAL ELECTRICAL CODE 70–17](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-20-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

Barry N. Hornberger, PECO Energy Company, PA [UT] Ron B. Chilton, North Carolina Department of Insurance,

Rep. Electric Light & Power Group/EEI NC [E]

John R. Kovacik, Underwriters Laboratories Incorporated, Rep. International Association of Electrical Inspectors

IL [RT] (Alt. to T. L. Baker)

Kenneth Krastins, Plug Power, Incorporated, NY [M] Brian L. Crise, NIETC, OR [L]

Rep. U.S. Fuel Cell Council Rep. International Brotherhood of Electrical Workers

(VL to 690, 692, 705) (Alt. to T. W. Stafford)

James S. Nasby, Master Control Systems, Inc., IL [M] Steven J. Fredette, UTC Cells, LLC, CT [M]

Rep. National Electrical Manufacturers Association Rep. U.S. Fuel Cell Council

Steven H. Pasternack, Intertek Testing Services NA, (Alt. to K. Krastins)

Incorporated, NY [RT] (VL to 690, 692, 705)

Todd W. Stafford, National Joint Apprentice & Training Ronald H. Minter, Thomas & Betts, TN [M]

Committee, IBEW-NJATC, TN [L] Rep. National Electrical Manufacturers Association

Rep. International Brotherhood of Electrical Workers (Alt. to J. S. Nasby)

LaVerne E. Stetson, Lincoln, NE [U] Duke W. Schamel, Copperhead Electric Inc, CA [IM]

Rep. American Society of Agricultural Engineers Rep. Independent Electrical Contractors, Incorporated

Herbert V. Whittall, Electrical Generating Systems (Alt. to T. D. Holleman)

Association, FL [M] Robert L. Simpson, Simpson Electrical Engineering

Rep. Electrical Generating Systems Association Company, GA [U]

Rep. Institute of Electrical & Electronics Engineers,

Alternates Incorporated

Daniel Batta, Jr., Constellation Generation Group, LLC, (Alt. to M. V. Glenn)

MD [UT] Richard Sobel, Quantum Electric Corporation, NY [IM]

Rep. Electric Light & Power Group/EEI Rep. National Electrical Contractors Association

(Alt. to B. N. Hornberger) (Alt. to T. H. Wood)

Sonya M. Bird, Underwriters Laboratories Incorporated, Dale A. Triffo, Shell Oil Products US, TX [U]

NC [RT] Rep. American Chemistry Council

(Alt. to J. R. Kovacik) (Alt. to D. L. Elkins)

CODE-MAKING PANEL NO. 14

Articles 500, 501, 502, 503, 504, 505, 506, 510, 511, 513, 514, 515, 516

Donald R. Cook, Chair

Shelby County Building Inspections, AL [E]

Rep. International Association of Electrical Inspectors

Troy Beall, B & D Electric Company, Incorporated, NM [IM] Alternates

Rep. National Electrical Contractors Association

A. W. Ballard, Crouse-Hinds, NY [M]

Edward M. Briesch, Underwriters Laboratories

Rep. National Electrical Manufacturers Association

Incorporated, IL [RT]

(Alt. to J. H. Kuczka)

Al Engler, EGS Electrical Group, IL [M]

Marc J. Bernsen, Southwestern Idaho Electrical JATC,

Rep. International Society for Measurement and Control

ID [L]

Mark Goodman, Jacobs Engineering Group, CA [U]

Rep. International Brotherhood of Electrical Workers

Rep. American Petroleum Institute

Gregory D. Hall, Better-Way Electric, Incorporated, CO [IM] (Alt. to J. A. Weldon)

Rep. Independent Electrical Contractors, Incorporated Mark W. Bonk, Cargill Incorporated, MN [U]

John Katunar, III, GE Global Asset Protection Services, Rep. Grain Elevator and Processing Society

MO [I] (Alt. to M. C. Wirfs)

Rep. GE Global Asset Protection Services Giovanni Hummel Borges, Underwriters Laboratories

Joseph H. Kuczka, Killark Electric Manufacturing Incorporated, Brasil [RT]

Company, MO [M] (Alt. to E. M. Briesch)

Rep. National Electrical Manufacturers Association James D. Cospolich, Waldemar S. Nelson & Company

William G. Lawrence, Jr., FM Global, MA [I] Incorporated, LA [U]

Rep. FM Global/FM Research Rep. Institute of Electrical & Electronics Engineers,

Jeremy Neagle, Intertek Testing Services NA, Incorporated, Incorporated

NY [RT] (Alt. to D. W. Zipse)

Mike O’Meara, Arizona Public Service Company, AZ [UT] Larry E. Fuhrman, City of Titusville, FL [E]

Rep. Electric Light & Power Group/EEI Rep. International Association of Electrical Inspectors

David B. Wechsler, The Dow Chemical Company, TX [U] (Alt. to D. R. Cook)

Rep. American Chemistry Council Nicholas P. Ludlam, FM Global, MA [I]

James A. Weldon, IBEW Local Union 728, FL [L] Rep. FM Global/FM Research

Rep. International Brotherhood of Electrical Workers (Alt. to W. G. Lawrence, Jr.)

Mark C. Wirfs, R & W Engineering Incorporated, OR [U] Michael E. McNeil, FMC Corporation/Bio Polymer, ME [U]

Rep. Grain Elevator and Processing Society Rep. American Chemistry Council

Donald W. Zipse, Zipse Electrical Engineering Incorporated, (Alt. to D. B. Wechsler)

PA [U] Ted H. Schnaare, Rosemount Incorporated, MN [M]

Rep. Institute of Electrical & Electronics Engineers, Rep. International Society for Measurement and Control

Incorporated (Alt. to A. Engler)

70–18 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-21-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

Francis M. Stone, Jr., Shell Exploration and Production Nonvoting

Company, TX [U] Eduardo N. Solano, Estudio Ingeniero Solano S.A.,

Rep. American Petroleum Institute Argentina [SE]

(Alt. to M. Goodman) Fred K. Walker, U.S. Air Force, FL [U]

Rep. TC on Airport Facilities

CODE-MAKING PANEL NO. 15

Articles 517, 518, 520, 525, 530, 540

Donald J. Talka, Chair

Underwriters Laboratories Incorporated, NY [RT]

James R. Duncan, Sparling Electrical Engineering, WA [U] Andrew White, IBEW Local Union 3, NY [L]

Rep. Institute of Electrical & Electronics Engineers, Rep. International Brotherhood of Electrical Workers

Incorporated James L. Wiseman, Square D Company, TN [M]

Tom Dunn, Butler Amusements, CA [U] Rep. National Electrical Manufacturers Association

Rep. Outdoor Amusement Business Association,

Incorporated Alternates

(VL to 525) James R. Cook, IBEW Local Union 364, IL [L]

Douglas S. Erickson, American Society for Healthcare Rep. International Brotherhood of Electrical Workers

Engineering, Virgin Islands [U] (Alt. to A. White)

Rep. American Society for Healthcare Engineering Matthew B. Dozier, IDesign Services, TN [U]

Michael B. Klein, Metropolitan Engineering, Incorporated, Rep. Institute of Electrical & Electronics Engineers,

DC [IM] Incorporated

Rep. Illuminating Engineering Society of North America (Alt. to J. R. Duncan)

(VL to 518, 520, 525, 530, 540) Samuel B. Friedman, BICC General Cable Corporation,

Edwin S. Kramer, Radio City Music Hall, NY [L] RI [M]

Rep. International Alliance of Theatrical Stage Employees Rep. National Electrical Manufacturers Association

(VL to 518, 520, 525, 530, 540) (Alt. to J. L. Wiseman)

Larry Lau, U.S. Department of Veterans Affairs, DC [U] Dale A. Hallerberg, Underwriters Laboratories Incorporated,

(VL to 517, 518) IL [RT]

Dennis W. Marshall, TAG Electric Companies, TX [IM] (Alt. to D. J. Talka)

Rep. Independent Electrical Contractors, Incorporated Mitchell K. Hefter, Entertainment Technology, TX [IM]

Rep. Illuminating Engineering Society of North America

Eugene E. Morgan, County of Clackamas, Oregon, OR [E]

(Alt. to M. B. Klein)

Rep. International Association of Electrical Inspectors

(VL to 518, 520, 525, 530, 540))

Hugh O. Nash, Jr., Nash Lipsey Burch, LLC, TN [SE]

Stanley D. Kahn, Tri-City Electric Company, Incorporated,

Rep. TC on Electrical Systems

CA [IM]

Bruce D. Shelly, Shelly Electric Company, Inc., PA [IM] Rep. National Electrical Contractors Association

Rep. National Electrical Contractors Association (Alt. to B. D. Shelly)

Donald J. Sherratt, Intertek Testing Services NA, Malinda Joyce Sampson, Minnesota Electricity Board,

Incorporated, MA [RT] MN [E]

Michael D. Skinner, CBS Studio Center, CA [U] Rep. International Association of Electrical Inspectors

Rep. Alliance of Motion Picture and Television Producers (Alt. to E. E. Morgan)

(VL to 518, 520, 525, 530, 540) James C. Seabury, III, Enterprise Electric, LLC, TN [IM]

Richard H. Smith, OG&E Electric Services, OK [UT] Rep. Independent Electrical Contractors, Incorporated

Rep. Electric Light & Power Group/EEI (Alt. to D. W. Marshall)

Kenneth E. Vannice, Leviton Manufacturing Company Steven R. Terry, Electronic Theatre Controls Incorporated,

Incorporated, OR [M] NY [M]

Rep. U.S. Institute for Theatre Technology Rep. U.S. Institute for Theatre Technology

(VL to 518, 520, 525, 530, 540) (Alt. to K. E. Vannice)

Michael Velvikis, High Voltage Maintenance Corporation, (VL to 518, 520, 525, 530, 540)

WI [IM] Rodney M. Young, Detroit Edison Company, MI [UT]

Rep. InterNational Electrical Testing Association Rep. Electric Light & Power Group/EEI

Incorporated (Alt. to R. H. Smith)

2005 Edition NATIONAL ELECTRICAL CODE 70–19](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-22-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

CODE-MAKING PANEL NO. 16

Articles 770, 800, 810, 820, 830

Stanley D. Kahn, Chair

Tri-City Electric Company, Incorporated, CA [IM]

Rep. National Electrical Contractors Association

J. Robert Boyer, Edwards Systems Technology, Chrysanthos Chrysanthou, Telcordia Technologies/SAIC,

Incorporated, NJ [M] NJ [U]

Rep. National Electrical Manufacturers Association Rep. Alliance for Telecommunications Industry Solutions

James E. Brunssen, Telcordia, NJ [U] (Alt. to J. E. Brunssen)

Rep. Alliance for Telecommunications Industry Solutions Terry C. Coleman, National Joint Apprentice & Training

Larry Chan, City of New Orleans, LA [E] Committee, TN [L]

Rep. International Association of Electrical Inspectors Rep. International Brotherhood of Electrical Workers

Gerald Lee Dorna, Belden Wire & Cable, IN [M] (Alt. to H. C. Ohde)

Rep. Insulated Cable Engineers Association Incorporated

William K. Hopple, Tyco/SimplexGrinnell, CA [M]

Roland W. Gubisch, Intertek Testing Services NA,

Rep. National Electrical Manufacturers Association

Incorporated, MA [RT]

Robert L. Hughes, The DuPont Company, TN [U] (Alt. to J. R. Boyer)

Rep. American Chemistry Council Dr. Stanley Kaufman, CableSafe/OFS, GA [M]

Robert W. Jensen, dbi-Telecommunication Infrastructure Rep. Insulated Cable Engineers Association Incorporated

Design, TX [M] (Alt. to G. L. Dorna)

Rep. Building Industry Consulting Services International Robert W. McCourt, Public Service Electric and Gas

Steven C. Johnson, Time Warner Cable, NC [UT] Company, NJ [UT]

Rep. National Cable & Telecommunications Association Rep. Electric Light & Power Group/EEI

Ronald G. Jones, Ronald G. Jones, P.E., TX [U] (Alt. to K. E. Todd)

Rep. Institute of Electrical & Electronics Engineers, William J. McCoy, Verizon Wireless, TX [U]

Incorporated Rep. Institute of Electrical & Electronics Engineers,

Barrett (Barry) Kalian, Underwriters Laboratories of Incorporated

Canada, ON, Canada [RT] (Alt. to R. G. Jones)

Harold C. Ohde, IBEW/NECA Technical Institute, IL [L] Robert P. McGann, City of Cambridge, MA [E]

Rep. International Brotherhood of Electrical Workers Rep. International Association of Electrical Inspectors

Joseph W. Rao, R.A.O. Electric Company, FL [IM] (Alt. to L. Chan)

Rep. Independent Electrical Contractors, Incorporated W. Douglas Pirkle, Pirkle Electric Company, Incorporated,

James W. Romlein, MV Labs LLC, WI [M]

GA [IM]

Rep. Telecommunications Industry Association

Rep. National Electrical Contractors Association

Kyle E. Todd, Entergy Corporation, TX [UT]

Rep. Electric Light & Power Group/EEI (Alt. to S. D. Kahn)

Luigi G. Prezioso, M. C. Dean, Incorporated, VA [IM]

Alternates Rep. Independent Electrical Contractors, Incorporated

Alan Amato, Times Fiber Communications, Incorporated, (Alt. to J. W. Rao)

CT [UT] Bradley C. Rowe, Underwriters Laboratories Incorporated,

Rep. National Cable & Telecommunications Association IL [RT]

(Alt. to S. C. Johnson) (Alt. to B. Kalian)

Donna Ballast, University of Texas at Austin, TX [M]

Rep. Building Industry Consulting Services International

Nonvoting

(Alt. to R. W. Jensen) Irving Mande, Westport, CT [M]

CODE-MAKING PANEL NO. 17

Articles 422, 424, 426, 427, 680, 682

Don W. Jhonson, Chair

Interior Electric, Incorporated, FL [IM]

Rep. National Electrical Contractors Association

Richard J. Cripps, Association of Home Appliance Walter Koessel, Intertek Testing Services NA, Incorporated,

Manufacturers, DC [M] MO [RT]

Rep. Association of Home Appliance Manufacturers Robert M. Milatovich, Clark County Building Department,

(VL to 422, 424) NV [E]

Bill Hanthorn, Tyco Thermal Controls, ON, Canada [M] Rep. International Association of Electrical Inspectors

Rep. Copper Development Association, Incorporated Marcos Ramirez, Hatfield-Reynolds Electric Company, AZ

Bruce R. Hirsch, Baltimore Gas & Electric Company, MD [IM]

[UT] Rep. Independent Electrical Contractors, Incorporated

Rep. Electric Light & Power Group/EEI Brian E. Rock, Hubbell Incorporated, CT [M]

Christopher T. Hutchings, Underwriters Laboratories Rep. National Electrical Manufacturers Association

Incorporated, CA [RT]

70–20 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-23-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

Anthony P. Sardina, UTC Carrier Corporation, NY [M] Paul Crivell, Kennedy Jenks Consultants, WA [U]

Rep. Air-Conditioning and Refrigeration Institute Rep. Institute of Electrical & Electronics Engineers,

(VL to 422, 424) Incorporated

Lee L. West, Balboa Instruments, Incorporated, CA [M] (Alt. to R. M. Yurkanin)

Rep. National Spa and Pool Institute James E. Maldonado, City of Tempe, AZ [E]

(VL to 680) Rep. International Association of Electrical Inspectors

Randy J. Yasenchak, IBEW Local Union 607, PA [L]

(Alt. to R. M. Milatovich)

Rep. International Brotherhood of Electrical Workers

Robert M. Yurkanin, Electran Process International Cannon Sun, Underwriters Laboratories Incorporated,

Incorporated, NJ [U] Taiwan [RT]

Rep. Institute of Electrical & Electronics Engineers, (Alt. to C. T. Hutchings)

Incorporated D. Harold Ware, Libra Electric Company, OK [IM]

Rep. National Electrical Contractors Association

Alternates (Alt. to D. W. Jhonson)

Dennis L. Baker, Springs & Sons Electrical Contractors Robert E. Wisenburg, Coates Heater Company,

Incorporated, AZ [IM] Incorporated, WA [M]

Rep. Independent Electrical Contractors, Incorporated Rep. National Spa and Pool Institute

(Alt. to M. Ramirez) (Alt. to L. L. West)

Mark R. Berner, PPL Electric Utilities Corporation, (VL to 680)

PA [UT]

Rep. Electric Light & Power Group/EEI Nonvoting

(Alt. to B. R. Hirsch)

William H. King, Jr., U.S. Consumer Product Safety

J. Ron Caccamese, Nathan Electric Company, LTD., TX [L]

Rep. International Brotherhood of Electrical Workers Commission, MD [C]

(Alt. to R. J. Yasenchak) (Alt. to A. M. Trotta)

Aaron B. Chase, Leviton Manufacturing Company, Andrew M. Trotta, U.S. Consumer Product Safety

Incorporated, NY [M] Commission, MD [C]

Rep. National Electrical Manufacturers Association

(Alt. to B. E. Rock)

CODE-MAKING PANEL NO. 18

Articles 406, 410, 411, 600, 605

Michael N. Ber, Chair

IEC, Houston, TX [IM]

Rep. Independent Electrical Contractors, Incorporated

Paul Costello, NECA and IBEW Local 90 JATC, CT [L] Alternates

Rep. International Brotherhood of Electrical Workers Robert T. Carlock, R. T. Carlock Company, TN [IM]

Kenneth A. Fetzer, Underwriters Laboratories Incorporated, Rep. Independent Electrical Contractors, Incorporated

NC [RT] (Alt. to M. N. Ber)

Stephen G. Kieffer, Kieffer & Company, Incorporated, Frederick L. Carpenter, Lithonia Lighting, GA [M]

WI [M] Rep. National Electrical Manufacturers Association

Rep. International Sign Association (Alt. to S. Rosenbaum)

(VL to 600) Amos D. Lowrance, Jr., City of Chattanooga, Tennessee,

Steven A. Larson, BWXT Y-12, LLC, TN [U] TN [E]

Rep. Institute of Electrical & Electronics Engineers, Rep. International Association of Electrical Inspectors

Incorporated (Alt. to T. S. Owens)

Ronald Michaelis, South Bend Vicinity Electrical JATC,

Michael S. O’Boyle, Genlyte Thomas Group, MA [M] IN [L]

Rep. American Lighting Association Rep. International Brotherhood of Electrical Workers

(VL to 410, 411) (Alt. to P. Costello)

Timothy S. Owens, City of San Diego, CA [E] Christopher P. O’Neil, National Grid USA Service

Rep. International Association of Electrical Inspectors Company, MA [UT]

Jim F. Pierce, Intertek Testing Services NA, Incorporated, Rep. Electric Light & Power Group/EEI

OR [RT] (Alt. to C. T. Wall)

Saul Rosenbaum, Leviton Manufacturing Company Alan M. Smith, France/Scott Fetzer Company, TN [M]

Incorporated, NY [M] Rep. International Sign Association

Rep. National Electrical Manufacturers Association (Alt. to S. G. Kieffer)

(VL to 600)

Michael W. Smith, Guarantee Electrical Company,

Rachna Stegall, Underwriters Laboratories Incorporated,

MO [IM] IL [RT]

Rep. National Electrical Contractors Association (Alt. to K. A. Fetzer)

Carl Tim Wall, Alabama Power Company, AL [UT] Charles M. Trout, Maron Electric Company, FL [IM]

Rep. Electric Light & Power Group/EEI Rep. National Electrical Contractors Association

Jack Wells, Pass & Seymour/Legrand, NY [M] (Alt. to M. W. Smith)

2005 Edition NATIONAL ELECTRICAL CODE 70–21](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-24-320.jpg)

![NATIONAL ELECTRICAL CODE COMMITTEE

CODE-MAKING PANEL NO. 19

Articles 545, 547, 550, 551, 552, 553, 555, 604, 675, Annex D, Examples D11 and D12

Robert A. McCullough, Chair

Ocean County Construction Inspection Department, NJ [E]

Rep. International Association of Electrical Inspectors

Barry Bauman, Alliant Energy, WI [U] Steven J. Blais, EGS Electrical Group, IL [M]

Rep. American Society of Agricultural Engineers Rep. National Electrical Manufacturers Association

James W. Finch, Kampgrounds of America, Incorporated, (Alt. to T. P. McNeive)

MT [U] Monte R. Ewing, Wisconsin Department of Commerce,

(VL to 550, 551, 552, 555) WI [E]

Bruce A. Hopkins, Recreation Vehicle Industry Association, Rep. International Association of Electrical Inspectors

VA [M] (Alt. to R. A. McCullough)

Rep. Recreation Vehicle Industry Association Thomas R. Lichtenstein, Underwriters Laboratories

(VL to 550, 551, 552) Incorporated, IL [RT]

Robert L. La Rocca, Underwriters Laboratories (Alt. to R. L. La Rocca)

Incorporated, NY [RT] Linda J. Little, IBEW Local Union 1, MO [L]

Timothy P. McNeive, Thomas & Betts Corporation, TN [M] Rep. International Brotherhood of Electrical Workers

Rep. National Electrical Manufacturers Association (Alt. to W. J. Tipton)

John Mikel, Skyline Corporation, IN [M] Suzanne Mark, National Association of RV Parks &

Rep. Manufactured Housing Institute Campgrounds, VA [U]

(VL to 550, 551, 552)

Rep. National Association of RV Parks & Campgrounds

Tug L. Miller, National Association of RV Parks &

(Alt. to T. L. Miller)

Campgrounds, CA [U]

(VL to 550, 551, 552)

Rep. National Association of RV Parks & Campgrounds

(VL to 550, 551, 552) N. Kent Morgan, AC Corporation, NC [IM]

Leslie Sabin-Mercado, San Diego Gas & Electric Company, Rep. Independent Electrical Contractors, Incorporated

CA [UT] (Alt. to W. A. Zanicchi)

Rep. Electric Light & Power Group/EEI Kent Perkins, Recreation Vehicle Industry Association,

William J. Tipton, IBEW Local Union 575, OH [L] VA [M]

Rep. International Brotherhood of Electrical Workers Rep. Recreation Vehicle Industry Association

Kenneth Weakley, Mountain Electric, Incorporated, (Alt. to B. A. Hopkins)

CA [IM] (VL to 550, 551, 552)

Rep. National Electrical Contractors Association John G. Sims, NTA Incorporated, IN [M]

William A. Zanicchi, AAA Certified Electric Incorporated, Rep. Manufactured Housing Institute

FL [IM] (Alt. to J. Mikel)

Rep. Independent Electrical Contractors, Incorporated (VL to 550, 551, 552)

Michael L. Zieman, RADCO, CA [RT] Keith G. Tinsey, Michigan State University, MI [U]

(VL to 545, 550, 551, 552) Rep. American Society of Agricultural Engineers

(Alt. to B. Bauman)

Alternates Raymond F. Tucker, Consulting Professional Engineer,

Glenn H. Ankenbrand, Conectiv Power, MD [UT] CA [RT]

Rep. Electric Light & Power Group/EEI (Alt. to M. L. Zieman)

(Alt. to L. Sabin-Mercado) (VL to 545, 550, 551, 552)

NFPA Electrical Engineering Division Technical Staff

Mark W. Earley, Assistant Vice President/Chief Electrical Lee F. Richardson, Senior Electrical Engineer

Engineer Richard J. Roux, Senior Electrical Specialist

Kenneth G. Mastrullo, Senior Electrical Specialist Jeffrey S. Sargent, Senior Electrical Specialist

Jean A. O’Connor, Electrical Project Specialist/Support Joseph V. Sheehan, Principal Electrical Engineer

Supervisor Donald W. Shields, Senior Electrical Specialist

NFPA Staff Editor

Joyce G. Grandy, Senior Project Editor

Note: Membership on a committee shall not in and of itself constitute an endorsement of the Association

or any document developed by the Committee on which the member serves.

Committee Scope: This Committee shall have primary responsibility for documents on minimizing

the risk of electricity as a source of electric shock and as a potential ignition source of fires and

explosions. It shall also be responsible for text to minimize the propagation of fire and explosions due

to electrical installations.

70–22 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-25-320.jpg)

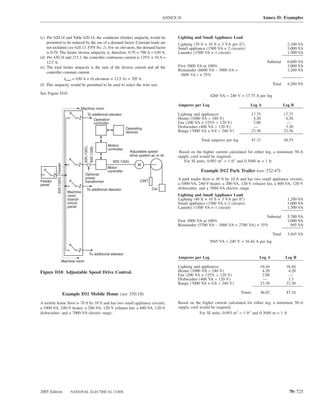

![220.14 ARTICLE 220 — BRANCH-CIRCUIT, FEEDER, AND SERVICE CALCULATIONS

lighting load. The floor area for each floor shall be calcu- Exception: The loads of outlets serving switchboards and

lated from the outside dimensions of the building, dwelling switching frames in telephone exchanges shall be waived

unit, or other area involved. For dwelling units, the calcu- from the calculations.

lated floor area shall not include open porches, garages, or

unused or unfinished spaces not adaptable for future use. (A) Specific Appliances or Loads. An outlet for a specific

appliance or other load not covered in 220.14(B) through

FPN: The unit values herein are based on minimum load

conditions and 100 percent power factor and may not pro- (L) shall be calculated based on the ampere rating of the

vide sufficient capacity for the installation contemplated. appliance or load served.

(B) Electric Dryers and Household Electric Cooking

Table 220.12 General Lighting Loads by Occupancy

Appliances. Load calculations shall be permitted as speci-

fied in 220.54 for electric dryers and in 220.55 for electric

Unit Load

ranges and other cooking appliances.

Volt-Amperes Volt-Amperes

per Square per Square (C) Motor Loads. Outlets for motor loads shall be calcu-

Type of Occupancy Meter Foot lated in accordance with the requirements in 430.22,

430.24, and 440.6.

Armories and auditoriums 11 1

Banks 39b 31⁄2b (D) Luminaires (Lighting Fixtures). An outlet supplying

Barber shops and beauty 33 3 luminaire(s) [lighting fixture(s)] shall be calculated based

parlors

Churches 11 1

on the maximum volt-ampere rating of the equipment and

Clubs 22 2 lamps for which the luminaire(s) [fixture(s)] is rated.

Court rooms 22 2

Dwelling unitsa 33 3 (E) Heavy-Duty Lampholders. Outlets for heavy-duty

Garages — commercial 6 1⁄2 lampholders shall be calculated at a minimum of 600 volt-

(storage) amperes.

Hospitals 22 2

Hotels and motels, including 22 2 (F) Sign and Outline Lighting. Sign and outline lighting

apartment houses without

outlets shall be calculated at a minimum of 1200 volt-

provision for cooking by

tenantsa amperes for each required branch circuit specified in

Industrial commercial (loft) 22 2 600.5(A).

buildings

Lodge rooms 17 11⁄2 (G) Show Windows. Show windows shall be calculated in

Office buildings 39b 31⁄2b accordance with either of the following:

Restaurants 22 2

Schools 33 3

(1) The unit load per outlet as required in other provisions

Stores 33 3 of this section

Warehouses (storage) 3 1⁄4

(2) At 200 volt-amperes per 300 mm (1 ft) of show

In any of the preceding window

occupancies except

one-family dwellings and (H) Fixed Multioutlet Assemblies. Fixed multioutlet as-

individual dwelling units of

two-family and multifamily semblies used in other than dwelling units or the guest

dwellings: rooms or guest suites of hotels or motels shall be calculated

Assembly halls and 11 1 in accordance with (H)(1) or (H)(2). For the purposes of

auditoriums this section, the calculation shall be permitted to be based

Halls, corridors, closets, 6 ⁄

12

on the portion that contains receptacle outlets.

stairways

Storage spaces 3 ⁄

14 (1) Where appliances are unlikely to be used simulta-

neously, each 1.5 m (5 ft) or fraction thereof of each

a

See 220.14(J). separate and continuous length shall be considered as

b

See 220.14(K). one outlet of not less than 180 volt-amperes.

(2) Where appliances are likely to be used simultaneously,

220.14 Other Loads — All Occupancies. In all occupan- each 300 mm (1 ft) or fraction thereof shall be consid-

cies, the minimum load for each outlet for general-use re- ered as an outlet of not less than 180 volt-amperes.

ceptacles and outlets not used for general illumination shall

not be less than that calculated in 220.14(A) through (L), (I) Receptacle Outlets. Except as covered in 220.14(J)

the loads shown being based on nominal branch-circuit and (K), receptacle outlets shall be calculated at not less

voltages. than 180 volt-amperes for each single or for each multiple

70–58 NATIONAL ELECTRICAL CODE 2005 Edition](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-61-320.jpg)

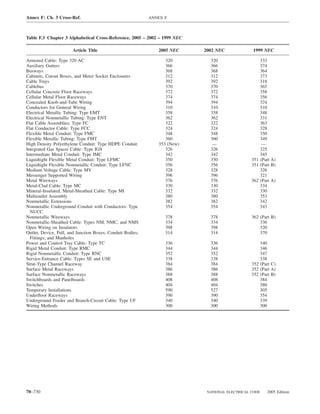

![ARTICLE 220 — BRANCH-CIRCUIT, FEEDER, AND SERVICE CALCULATIONS 220.80

Table 220.54 Demand Factors for Household Electric 220.60 Noncoincident Loads. Where it is unlikely that

Clothes Dryers two or more noncoincident loads will be in use simulta-

neously, it shall be permissible to use only the largest

Number of Demand Factor load(s) that will be used at one time for calculating the total

Dryers (Percent) load of a feeder or service.

1–4 100%

5 85% 220.61 Feeder or Service Neutral Load.

6 75% (A) Basic Calculation. The feeder or service neutral load

7 65% shall be the maximum unbalance of the load determined by

8 60% this article. The maximum unbalanced load shall be the

9 55% maximum net calculated load between the neutral and any

10 50% one ungrounded conductor.

11 47%

12–22 % = 47 – (number of dryers − 11) Exception: For 3-wire, 2-phase or 5-wire, 2-phase sys-

tems, the maximum unbalanced load shall be the maximum

23 35% net calculated load between the neutral and any one un-

grounded conductor multiplied by 140 percent.

24–42 % = 35 – [0.5 × (number of dryers − 23)]

(B) Permitted Reductions. A service or feeder supplying

43 and over 25%

the following loads shall be permitted to have an additional

demand factor of 70 percent applied to the amount in

220.61(B)(1) or portion of the amount in 220.61(B)(2) de-

FPN No. 1: See Example D5(A) in Annex D.

termined by the basic calculation:

FPN No. 2: See Table 220.56 for commercial cooking (1) A feeder or service supplying household electric

equipment. ranges, wall-mounted ovens, counter-mounted cooking

FPN No. 3: See the examples in Annex D. units, and electric dryers, where the maximum unbal-

anced load has been determined in accordance with

220.56 Kitchen Equipment — Other Than Dwelling Table 220.55 for ranges and Table 220.54 for dryers

Unit(s). It shall be permissible to calculate the load for (2) That portion of the unbalanced load in excess of 200 am-

commercial electric cooking equipment, dishwasher peres where the feeder or service is supplied from a

booster heaters, water heaters, and other kitchen equipment 3-wire dc or single-phase ac system, or a 4-wire, 3-phase;

in accordance with Table 220.56. These demand factors 3-wire, 2-phase system, or a 5-wire, 2-phase system

shall be applied to all equipment that has either thermo-

static control or intermittent use as kitchen equipment. (C) Prohibited Reductions. There shall be no reduction of

These demand factors shall not apply to space-heating, ven- the neutral or grounded conductor capacity applied to the

amount in 220.61(C)(1), or portion of the amount in (C)(2),

tilating, or air-conditioning equipment.

from that determined by the basic calculation:

However, in no case shall the feeder or service calcu-

lated load be less than the sum of the largest two kitchen (1) Any portion of a 3-wire circuit consisting of 2-phase

equipment loads. wires and the neutral of a 4-wire, 3-phase, wye-

connected system

(2) That portion consisting of nonlinear loads supplied

from a 4-wire, wye-connected, 3-phase system

Table 220.56 Demand Factors for Kitchen Equipment —

Other Than Dwelling Unit(s) FPN No. 1: See Examples D1(A), D1(B), D2(B), D4(A),

and D5(A) in Annex D.

Number of Units of Demand Factor

Equipment (Percent) FPN No. 2: A 3-phase, 4-wire, wye-connected power sys-

tem used to supply power to nonlinear loads may necessi-

tate that the power system design allow for the possibility

1 100 of high harmonic neutral currents.

2 100

3 90

4 80 IV. Optional Feeder and Service Load Calculations

5 70

6 and over 65 220.80 General. Optional feeder and service load calcula-

tions shall be permitted in accordance with Part IV.

2005 Edition NATIONAL ELECTRICAL CODE 70–61](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-64-320.jpg)

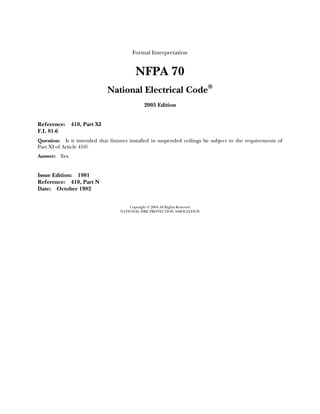

![ARTICLE 240 — OVERCURRENT PROTECTION 240.21

(A) Branch-Circuit Conductors. Branch-circuit tap con- (3) Taps Supplying a Transformer [Primary Plus Sec-

ductors meeting the requirements specified in 210.19 shall ondary Not Over 7.5 m (25 ft) Long]. Where the tap

be permitted to have overcurrent protection located as conductors supply a transformer and comply with all the

specified in that section. following conditions:

(1) The conductors supplying the primary of a transformer

(B) Feeder Taps. Conductors shall be permitted to be have an ampacity at least one-third the rating of the

tapped, without overcurrent protection at the tap, to a feeder as overcurrent device protecting the feeder conductors.

specified in 240.21(B)(1) through (B)(5). The provisions of (2) The conductors supplied by the secondary of the trans-

240.4(B) shall not be permitted for tap conductors. former shall have an ampacity that is not less than the

value of the primary-to-secondary voltage ratio multi-

(1) Taps Not Over 3 m (10 ft) Long. Where the length of plied by one-third of the rating of the overcurrent de-

the tap conductors does not exceed 3 m (10 ft) and the tap vice protecting the feeder conductors.

conductors comply with all of the following: (3) The total length of one primary plus one secondary con-

(1) The ampacity of the tap conductors is ductor, excluding any portion of the primary conductor

that is protected at its ampacity, is not over 7.5 m (25 ft).

a. Not less than the combined calculated loads on the

circuits supplied by the tap conductors, and (4) The primary and secondary conductors are protected

from physical damage by being enclosed in an ap-

b. Not less than the rating of the device supplied by

proved raceway or by other approved means.

the tap conductors or not less than the rating of the

overcurrent-protective device at the termination of (5) The secondary conductors terminate in a single circuit

the tap conductors. breaker or set of fuses that limit the load current to not

more than the conductor ampacity that is permitted by

(2) The tap conductors do not extend beyond the switch- 310.15.

board, panelboard, disconnecting means, or control de-

(4) Taps Over 7.5 m (25 ft) Long. Where the feeder is in

vices they supply.

a high bay manufacturing building over 11 m (35 ft) high at

(3) Except at the point of connection to the feeder, the tap walls and the installation complies with all the following

conductors are enclosed in a raceway, which shall ex- conditions:

tend from the tap to the enclosure of an enclosed (1) Conditions of maintenance and supervision ensure that

switchboard, panelboard, or control devices, or to the only qualified persons service the systems.

back of an open switchboard. (2) The tap conductors are not over 7.5 m (25 ft) long

(4) For field installations where the tap conductors leave horizontally and not over 30 m (100 ft) total length.

the enclosure or vault in which the tap is made, the (3) The ampacity of the tap conductors is not less than

rating of the overcurrent device on the line side of the one-third the rating of the overcurrent device protecting

tap conductors shall not exceed 10 times the ampacity the feeder conductors.

of the tap conductor. (4) The tap conductors terminate at a single circuit breaker

or a single set of fuses that limit the load to the ampac-

FPN: For overcurrent protection requirements for lighting

and appliance branch-circuit panelboards and certain power ity of the tap conductors. This single overcurrent de-

panelboards, see 408.36(A), (B), and (E). vice shall be permitted to supply any number of addi-

tional overcurrent devices on its load side.

(2) Taps Not Over 7.5 m (25 ft) Long. Where the length (5) The tap conductors are protected from physical damage

of the tap conductors does not exceed 7.5 m (25 ft) and the by being enclosed in an approved raceway or by other

tap conductors comply with all the following: approved means.

(1) The ampacity of the tap conductors is not less than (6) The tap conductors are continuous from end-to-end and

one-third of the rating of the overcurrent device pro- contain no splices.

tecting the feeder conductors. (7) The tap conductors are sized 6 AWG copper or 4 AWG

(2) The tap conductors terminate in a single circuit breaker aluminum or larger.

or a single set of fuses that will limit the load to the (8) The tap conductors do not penetrate walls, floors, or

ampacity of the tap conductors. This device shall be ceilings.

permitted to supply any number of additional overcur- (9) The tap is made no less than 9 m (30 ft) from the floor.

rent devices on its load side. (5) Outside Taps of Unlimited Length. Where the con-

(3) The tap conductors are protected from physical damage ductors are located outdoors of a building or structure, ex-

by being enclosed in an approved raceway or by other cept at the point of load termination, and comply with all of

approved means. the following conditions:

2005 Edition NATIONAL ELECTRICAL CODE 70–85](https://image.slidesharecdn.com/nechandbookversin2005compacta-100921141249-phpapp02/85/Nec-handbook-version-2005-compacta-88-320.jpg)

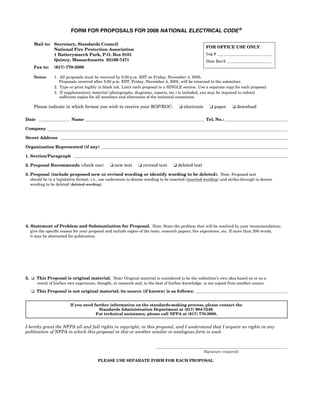

![240.86 ARTICLE 240 — OVERCURRENT PROTECTION

of the circuit breaker’s voltage rating and the nominal volt- (A) Feeder and Branch-Circuit Conductors. Feeder and

age between any two conductors does not exceed the higher branch-circuit conductors shall be protected at the point the

value of the circuit breaker’s voltage rating. conductors receive their supply as permitted in 240.21 or as

otherwise permitted in 240.92(B), (C), or (D).

FPN: Proper application of molded case circuit breakers

on 3-phase systems, other than solidly grounded wye, par- (B) Transformer Secondary Conductors of Separately

ticularly on corner grounded delta systems, considers the Derived Systems. Conductors shall be permitted to be con-

circuit breakers’ individual pole-interrupting capability. nected to a transformer secondary of a separately derived sys-

tem, without overcurrent protection at the connection, where

240.86 Series Ratings. Where a circuit breaker is used on the conditions of 240.92(B)(1), (B)(2), and (B)(3) are met.