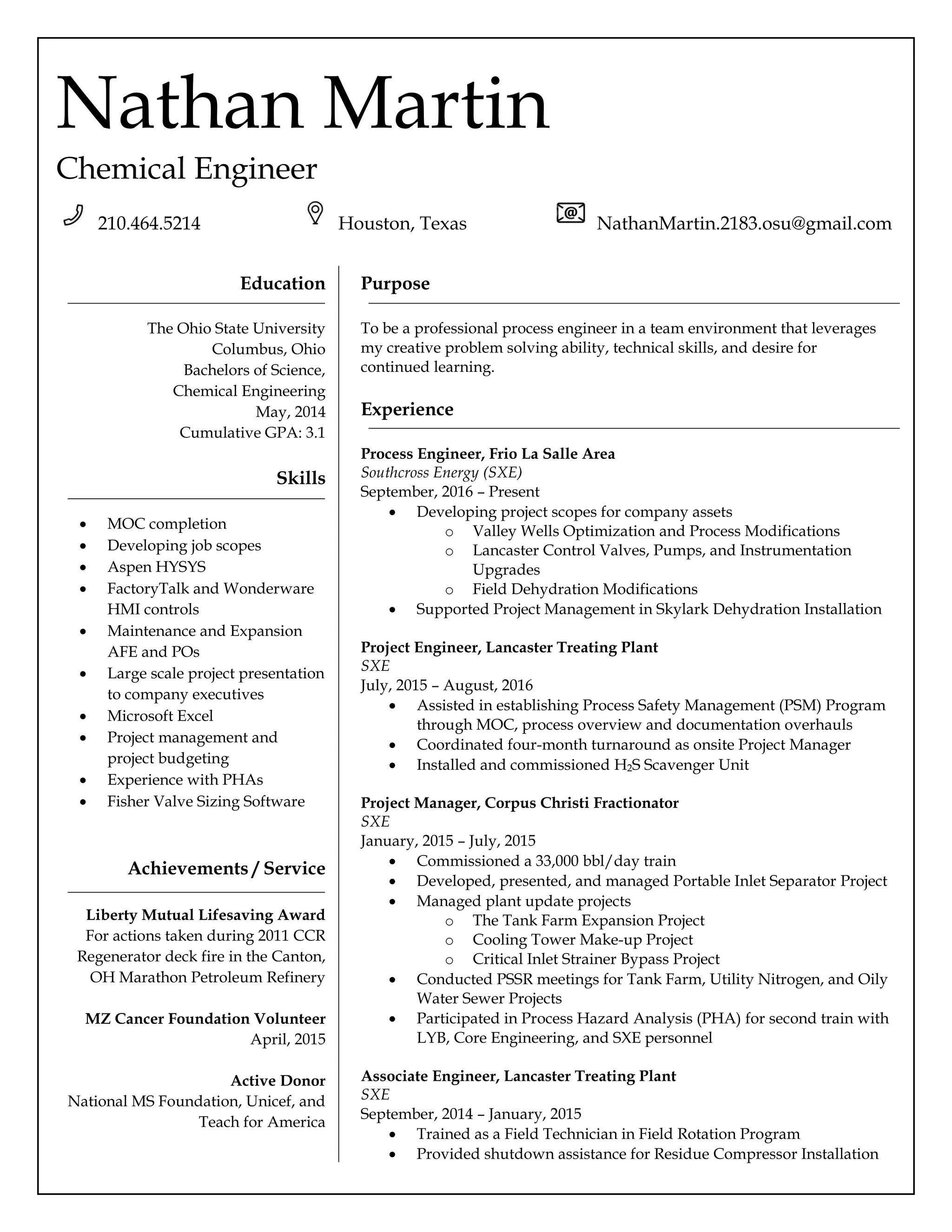

Nathan Martin is a chemical engineer seeking a position as a process engineer. He has over 3 years of experience as a process engineer and project manager for Southcross Energy, where he has led projects involving process modifications, turnarounds, and new equipment installation. Martin has a Bachelor's of Science in Chemical Engineering from Ohio State University and skills in areas such as process safety management, project management, and process simulation software. He has also received recognition for his actions during an emergency situation at a Marathon Petroleum refinery.