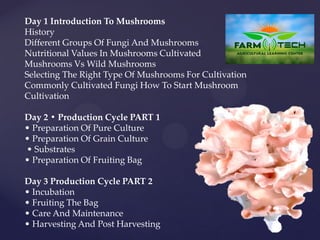

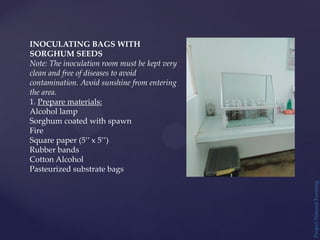

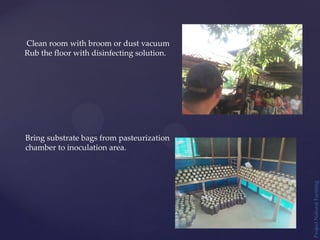

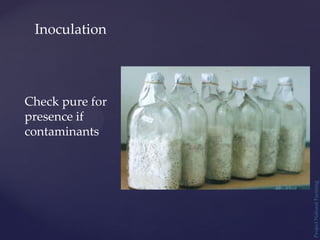

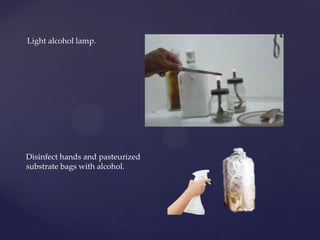

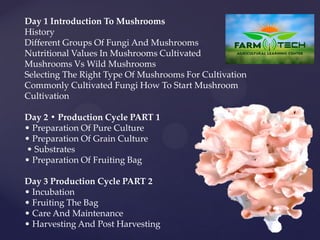

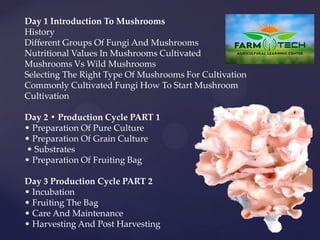

The document provides information about starting mushroom cultivation, including three key days of training:

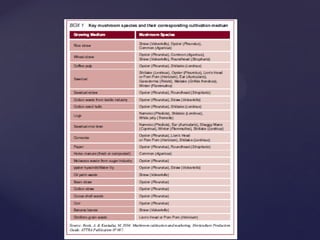

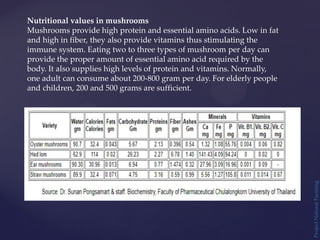

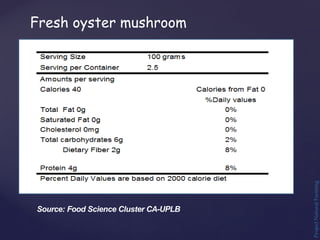

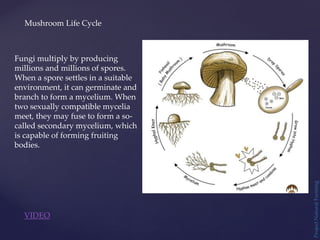

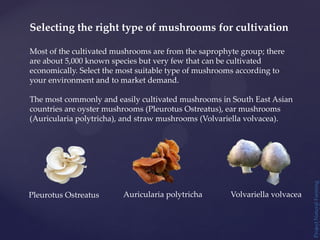

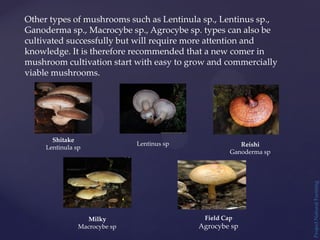

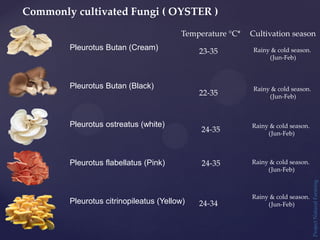

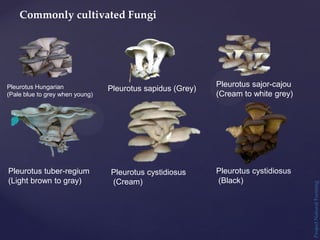

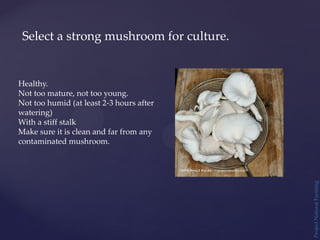

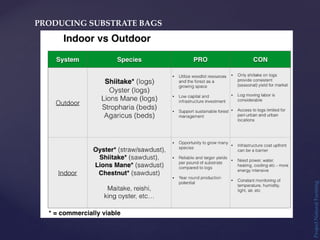

- Day 1 covers the history of mushrooms, types of fungi, nutritional value of cultivated mushrooms, and selecting mushrooms for cultivation.

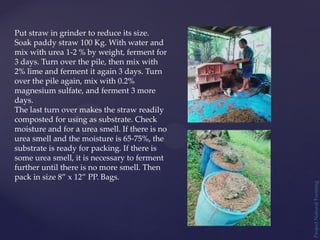

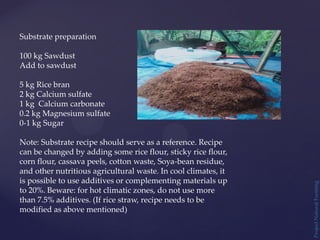

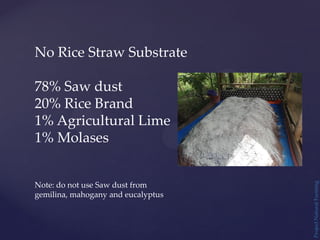

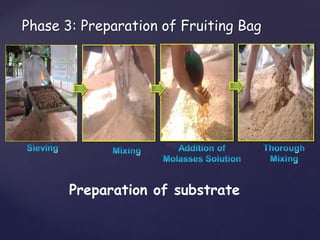

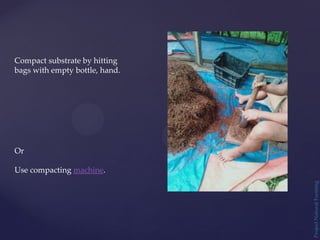

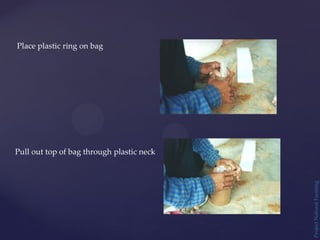

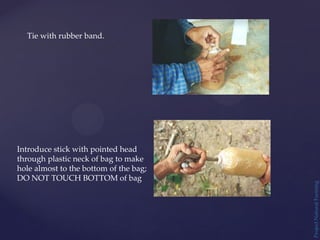

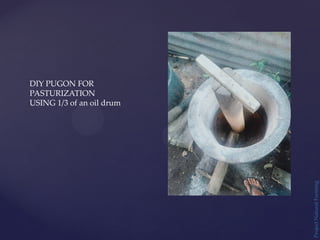

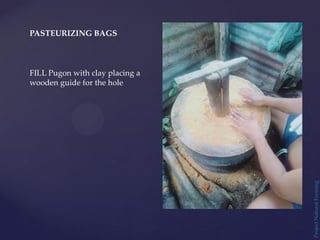

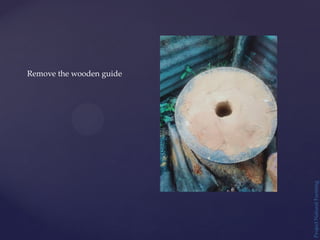

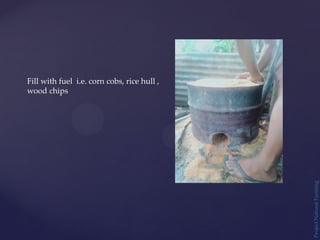

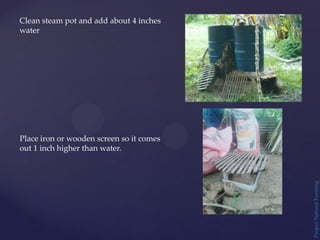

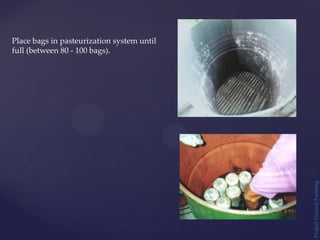

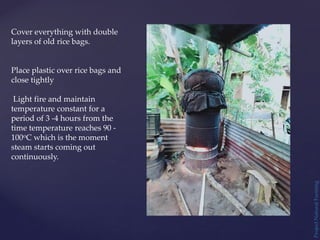

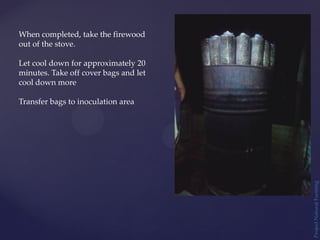

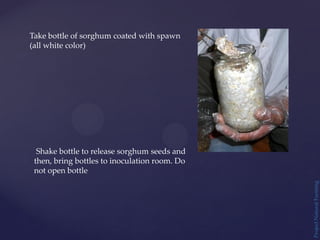

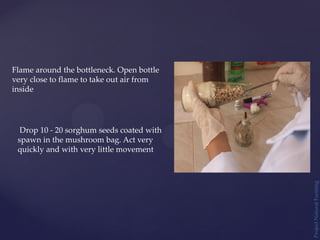

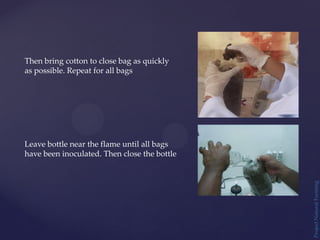

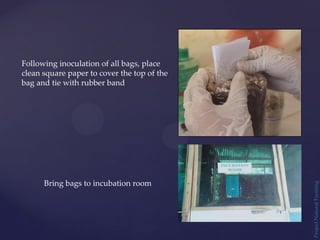

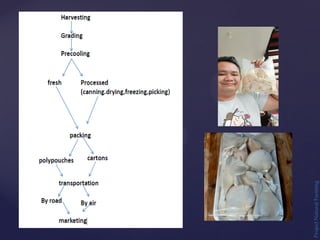

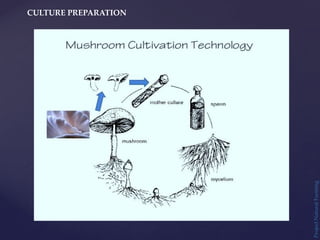

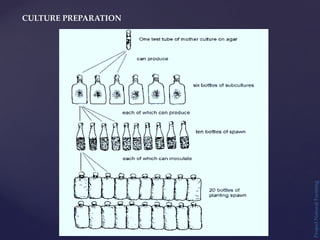

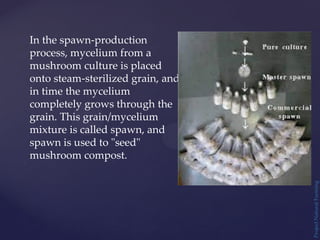

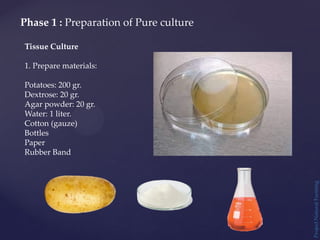

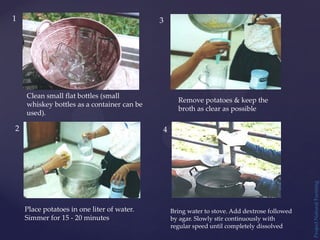

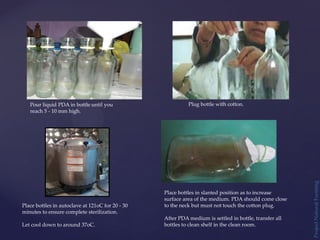

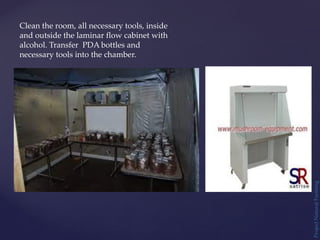

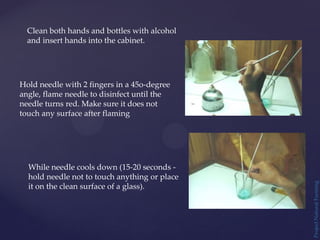

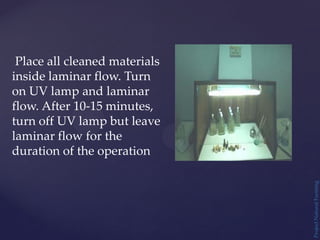

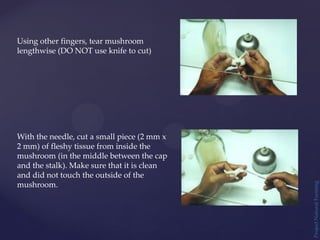

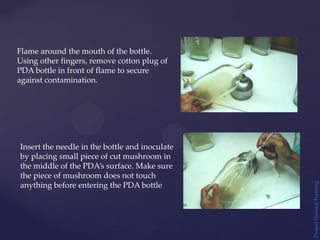

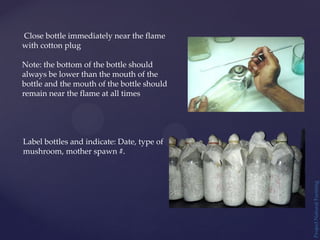

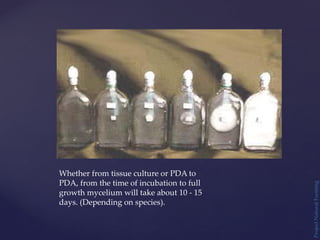

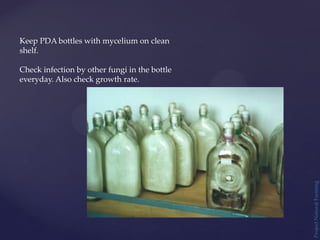

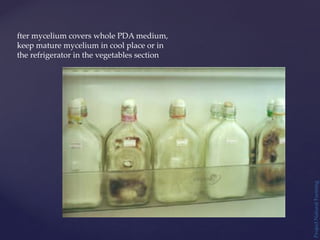

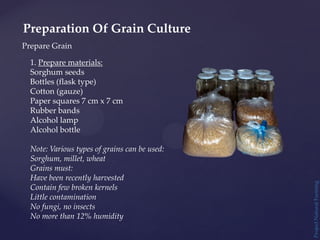

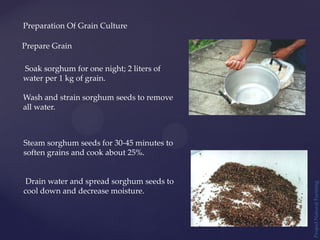

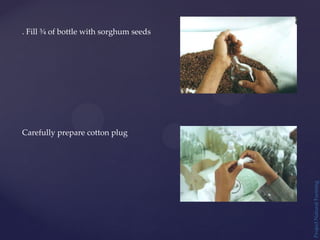

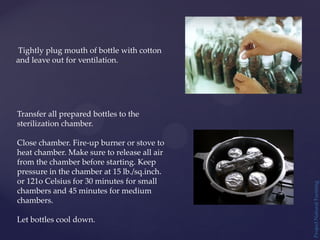

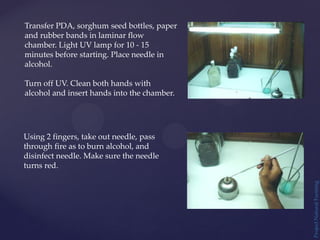

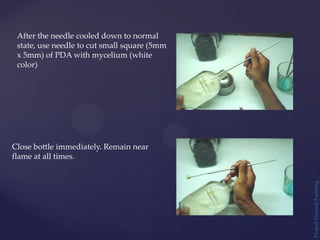

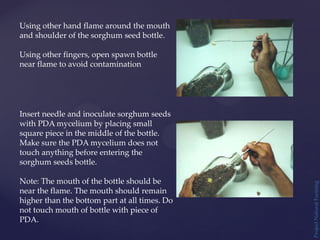

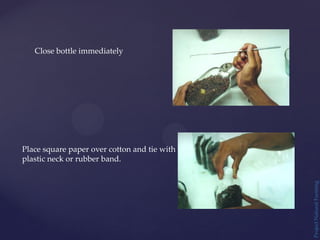

- Day 2 discusses the production cycle, including preparing pure and grain cultures, substrates, and fruiting bags.

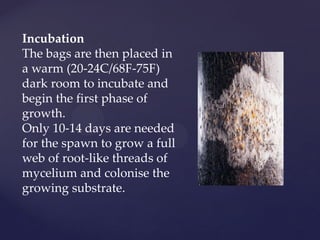

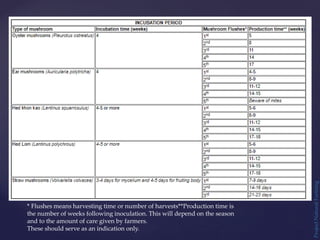

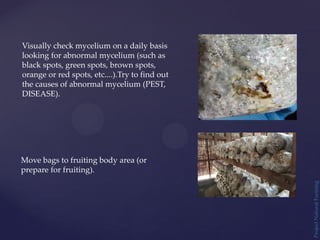

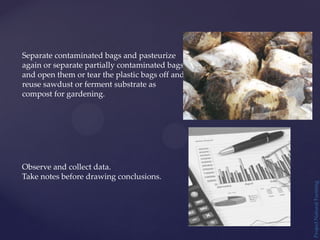

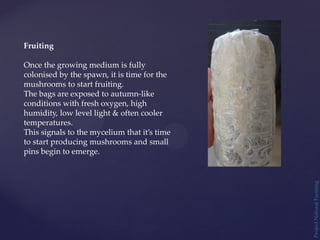

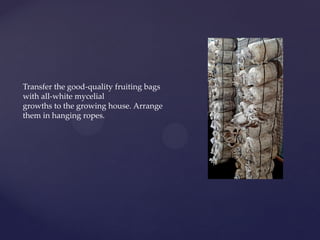

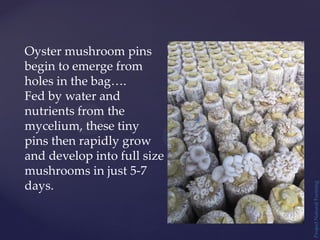

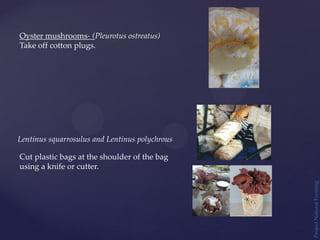

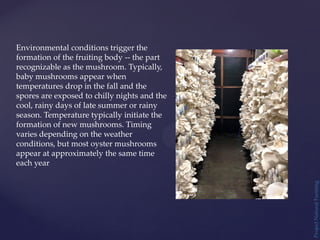

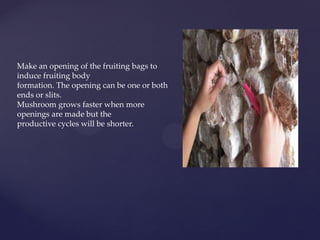

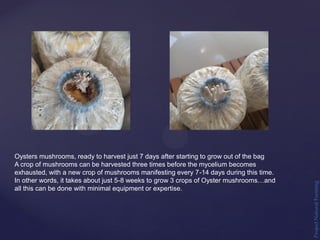

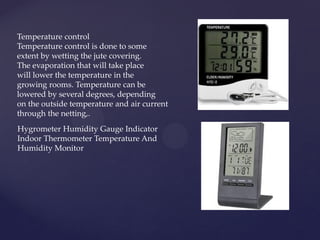

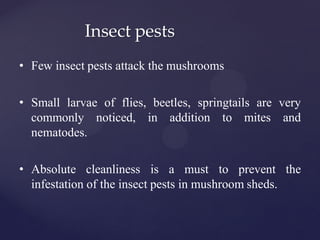

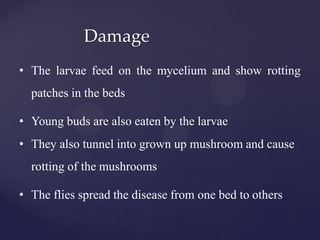

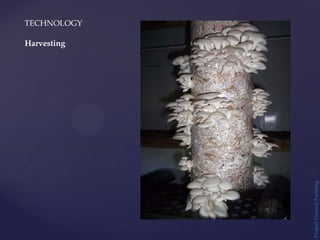

- Day 3 continues the production cycle with incubation, fruiting, care/maintenance, and harvesting.

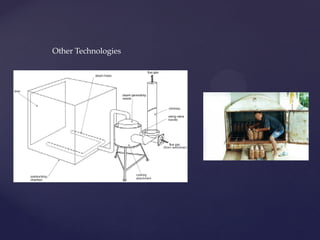

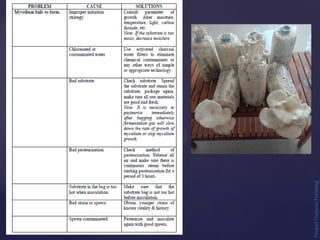

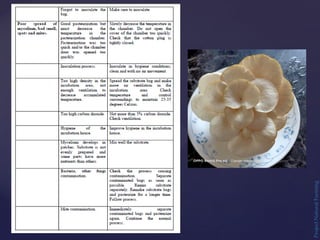

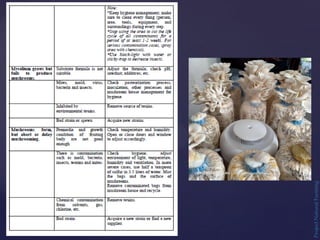

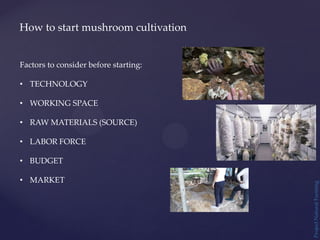

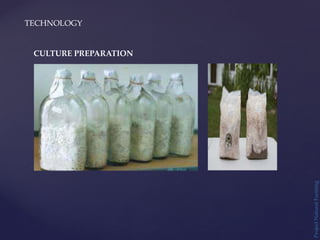

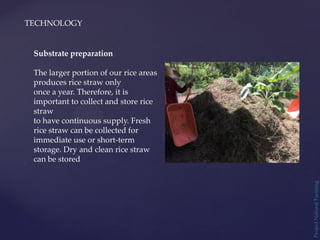

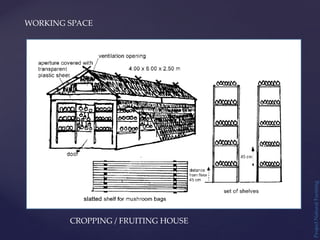

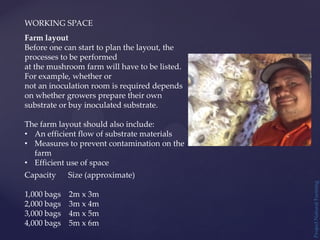

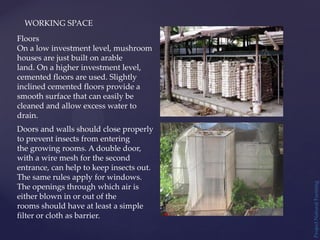

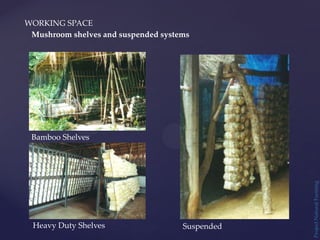

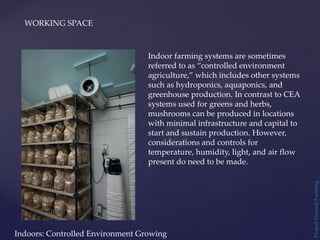

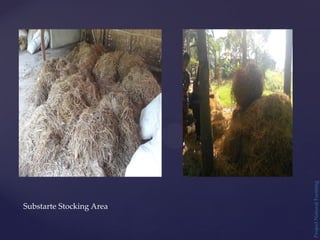

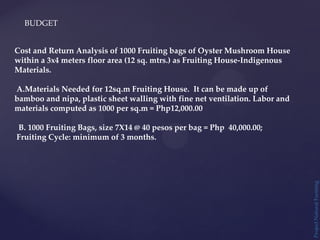

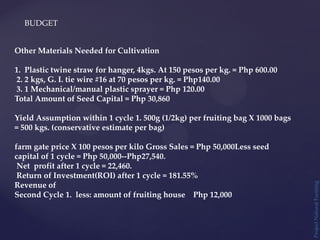

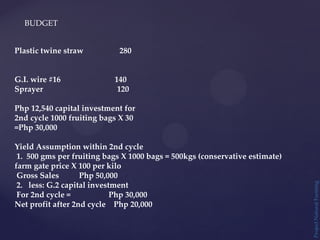

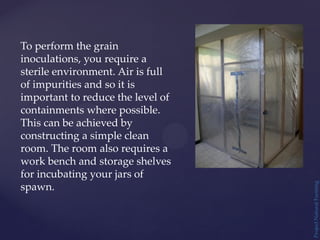

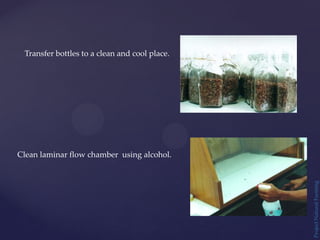

The document then discusses factors to consider such as technology, working space, raw materials, labor, budget, and market before starting a mushroom cultivation business. It provides details on culture preparation, substrate preparation, filling/heat treatment, spawn run, fruiting, and harvesting. Floor plans and

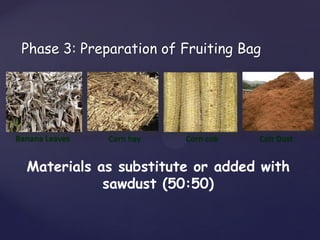

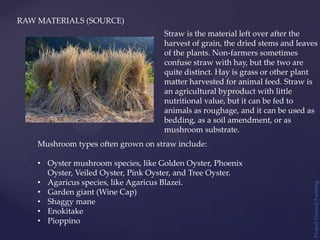

![RAW MATERIALS (SOURCE)

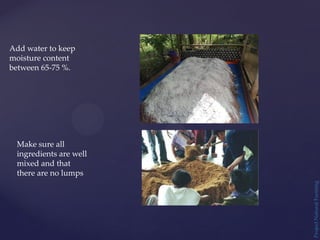

Saw dust or wood-chips—or, better yet,

both—make a good, productive substrate,

but are usually mixed with bran of some

type (grain or soy) for added nutrition[iv].

As with logs, the species of tree the

material came from matters, but many

hardwoods are suitable and material from

different species can be mixed. There are

many different recipes, each with their

advantages and disadvantages for different

crops.

Growers with access to waste sawdust and chips may be able to get material for

free. Otherwise, pellets of compressed hardwood sawdust are available at

reasonable prices. Just soak the pellets in water and they break apart easily.

Mushrooms that do well on sawdust mixes include:

• Reishi

• Lion’s mane

• Shiitaki

• Maitake

• King oyster

Project

Natural

Farming](https://image.slidesharecdn.com/mushprodpresentation-230125142211-dec275c1/85/MUSHPROD-PRESENTATION-pdf-102-320.jpg)