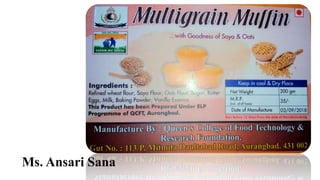

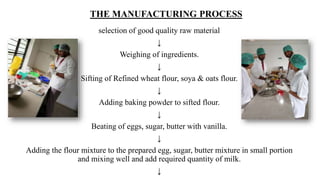

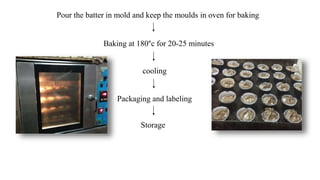

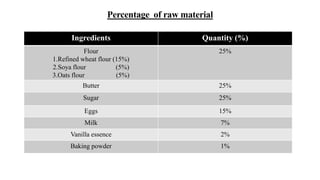

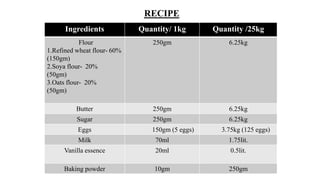

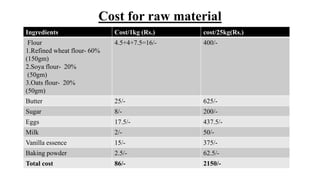

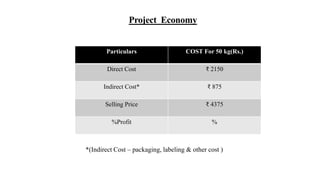

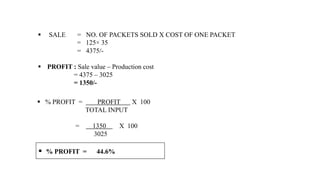

The document discusses a study on the preparation and marketing of multigrain muffins, detailing the nutritious ingredients such as oats and soy flour. It outlines the mission and objectives of the program, including skill development in food production and marketing. The project shows high economic feasibility and consumer acceptability, emphasizing the muffins' health benefits and successful marketing strategy.