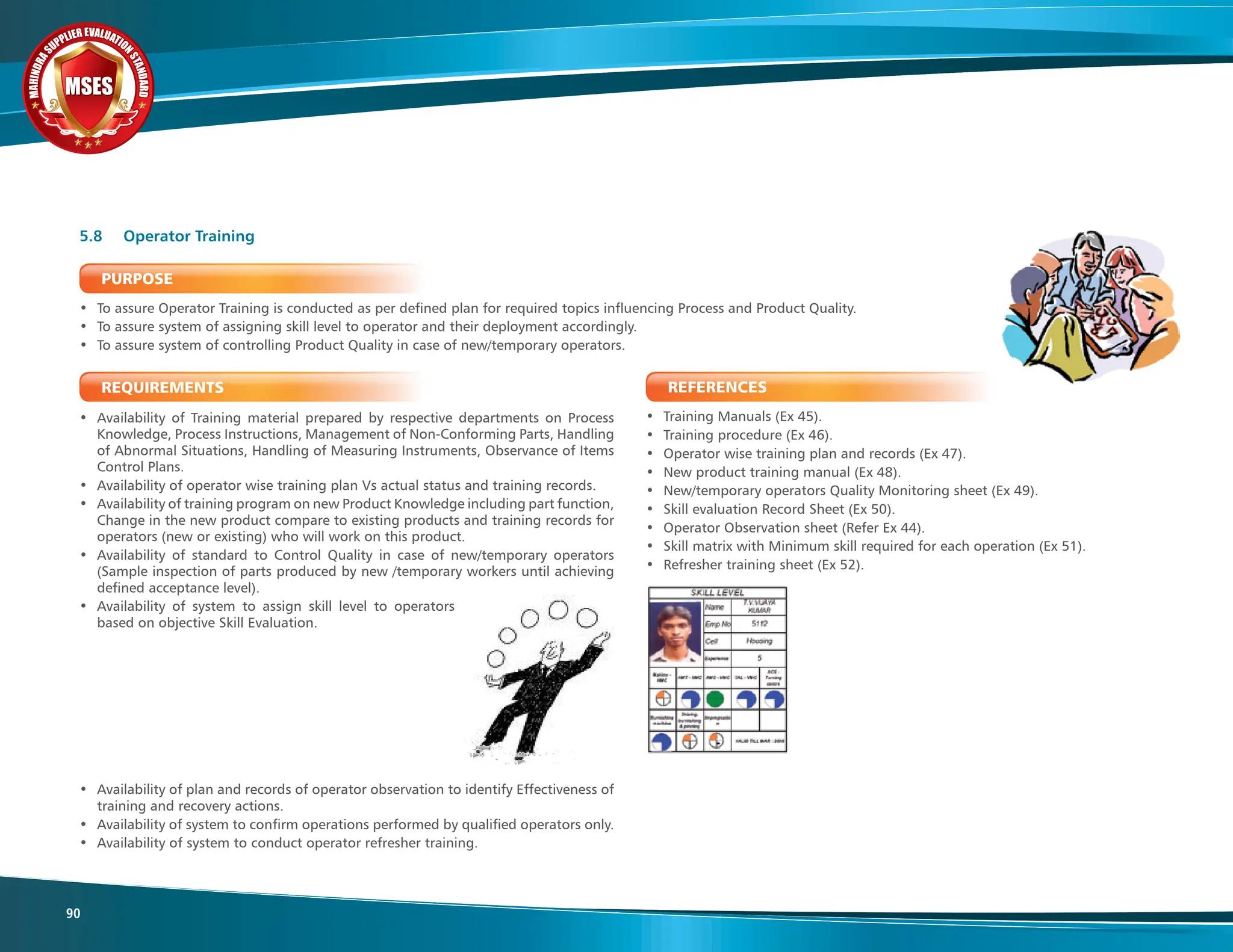

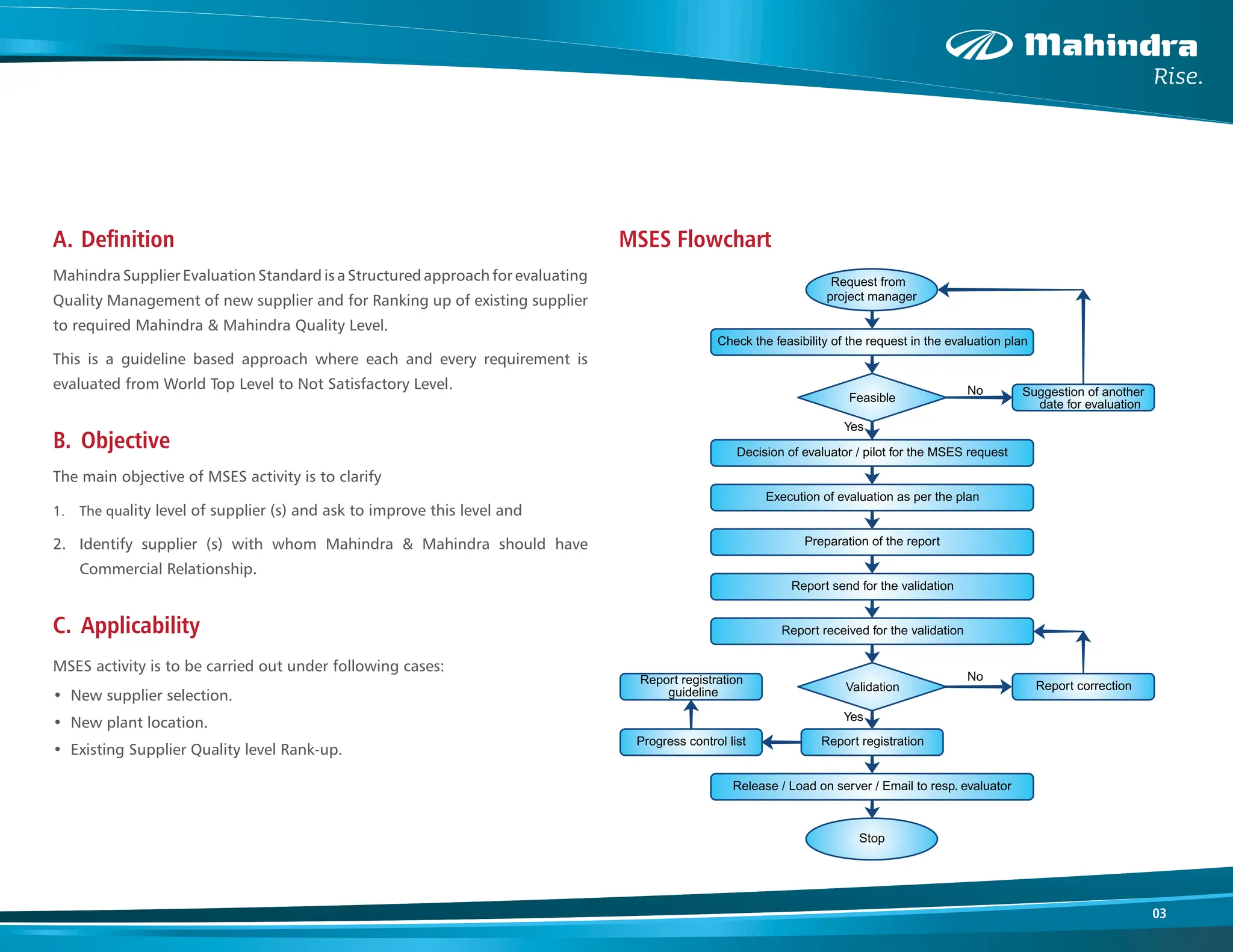

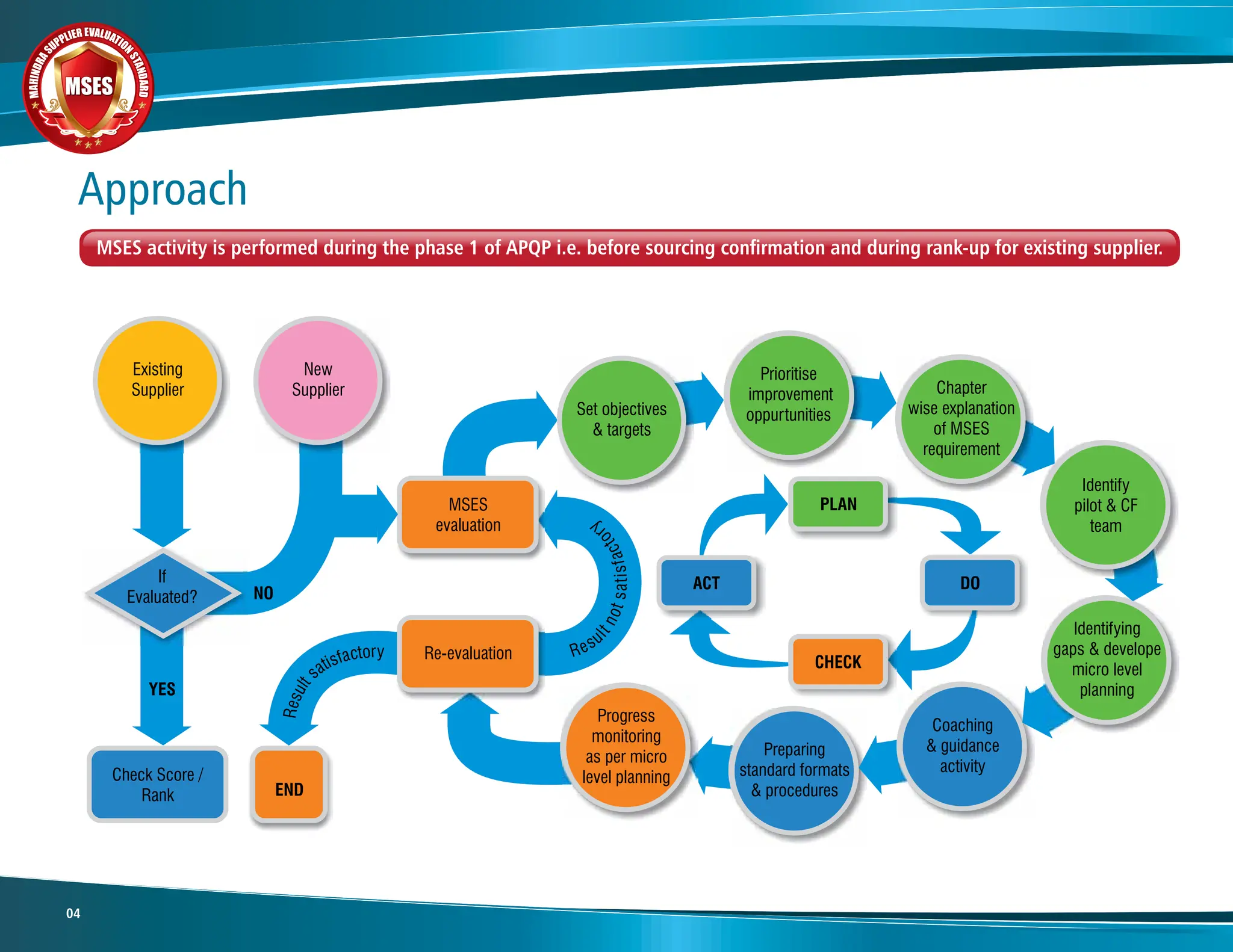

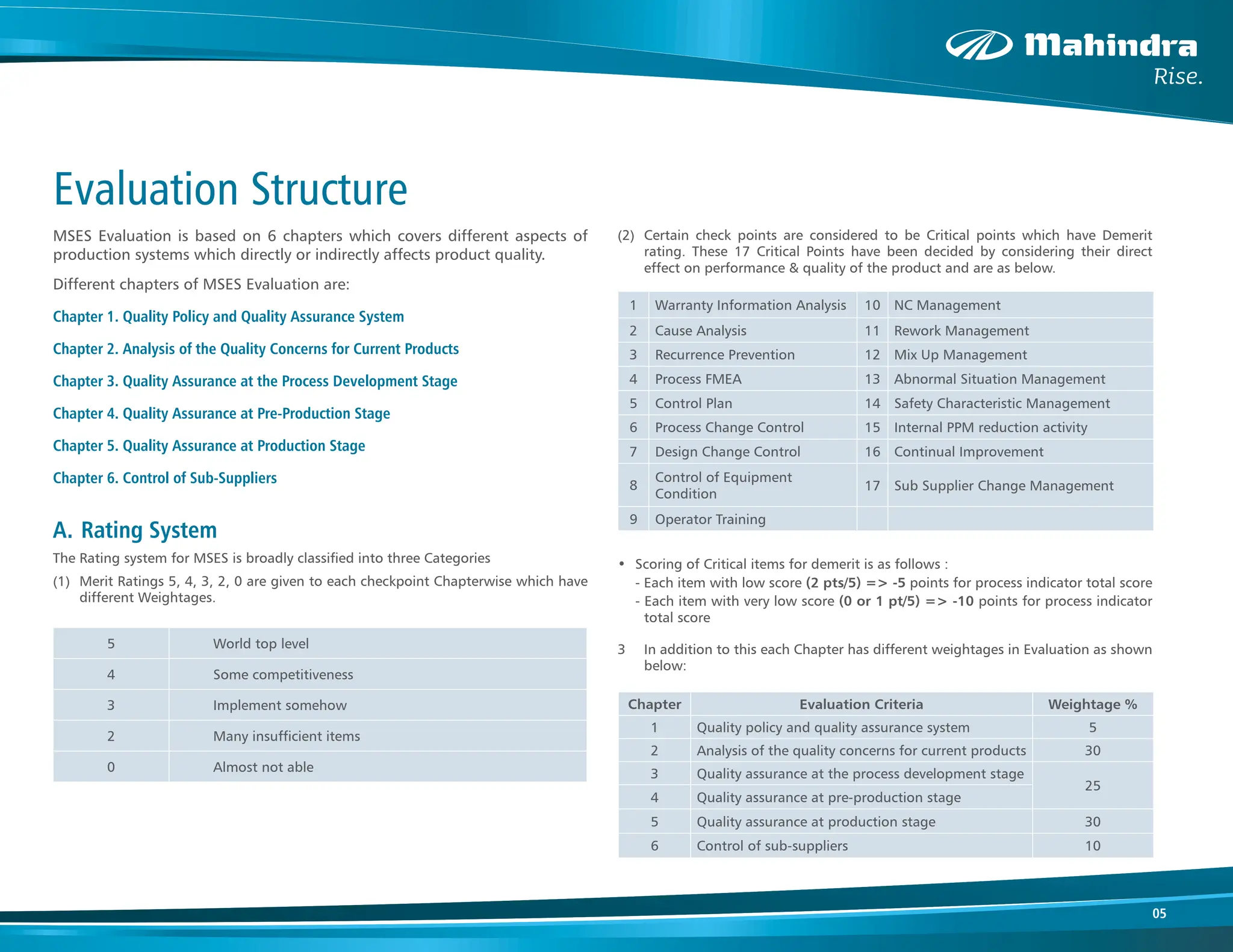

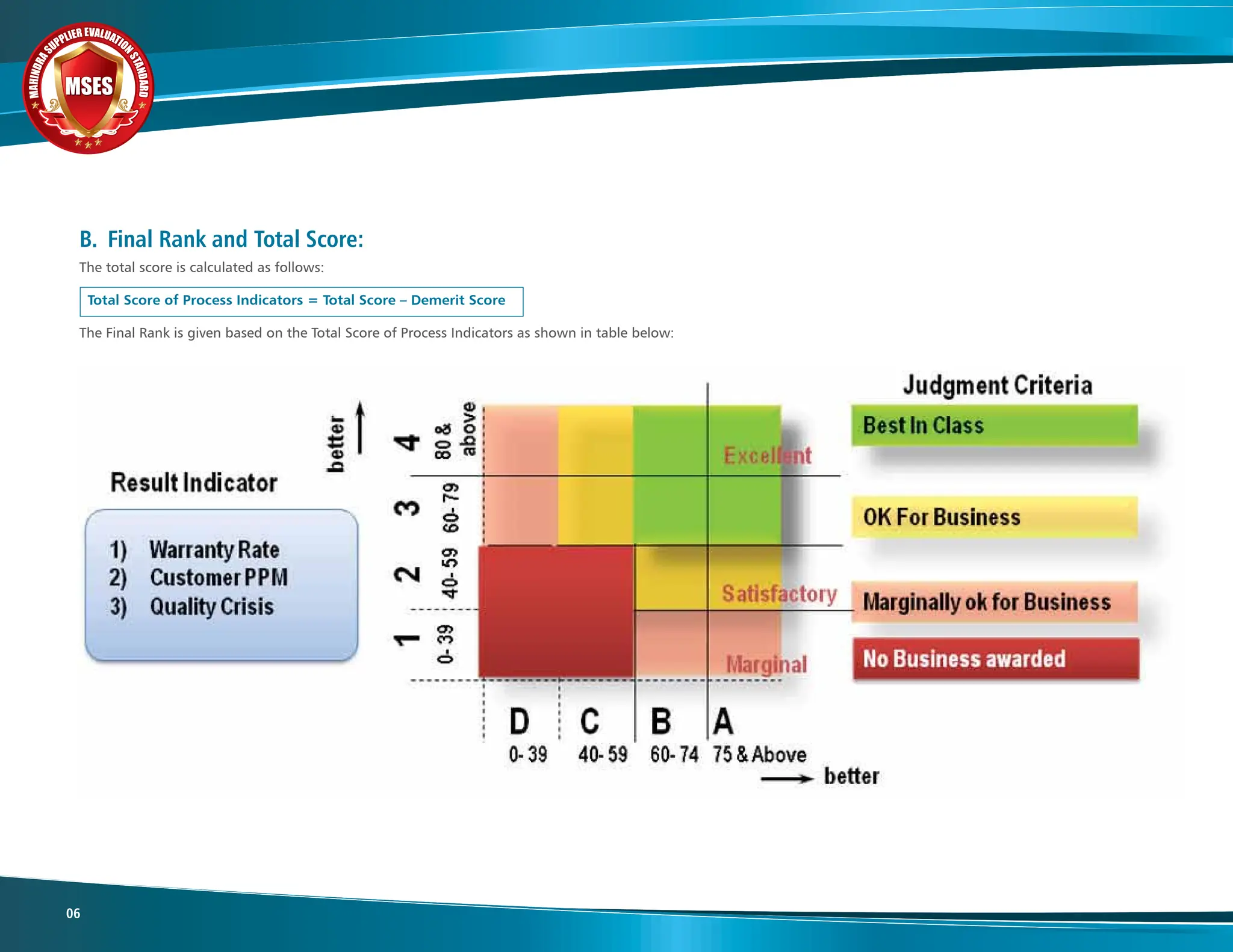

The document introduces Mahindra's Supplier Evaluation Standard (MSES) which provides a structured approach to evaluate suppliers' quality management systems. MSES consists of 6 chapters that assess different aspects of production related to quality. It establishes a rating system from 5 (world top level) to 0 (not satisfactory) for checkpoints in each chapter. Certain critical checkpoints can receive demerit points depending on the score. MSES is used to evaluate new suppliers, new plant locations, and to improve the quality level of existing suppliers in line with Mahindra's requirements. The goal is to ensure suppliers have robust quality systems, processes, and management to meet Mahindra's quality and delivery needs.

![M

A

H

I

N

D

R

A

SUPPLIER EVALUATIO

N

S

T

A

N

D

A

R

D

MSES

MSES

MSES

32

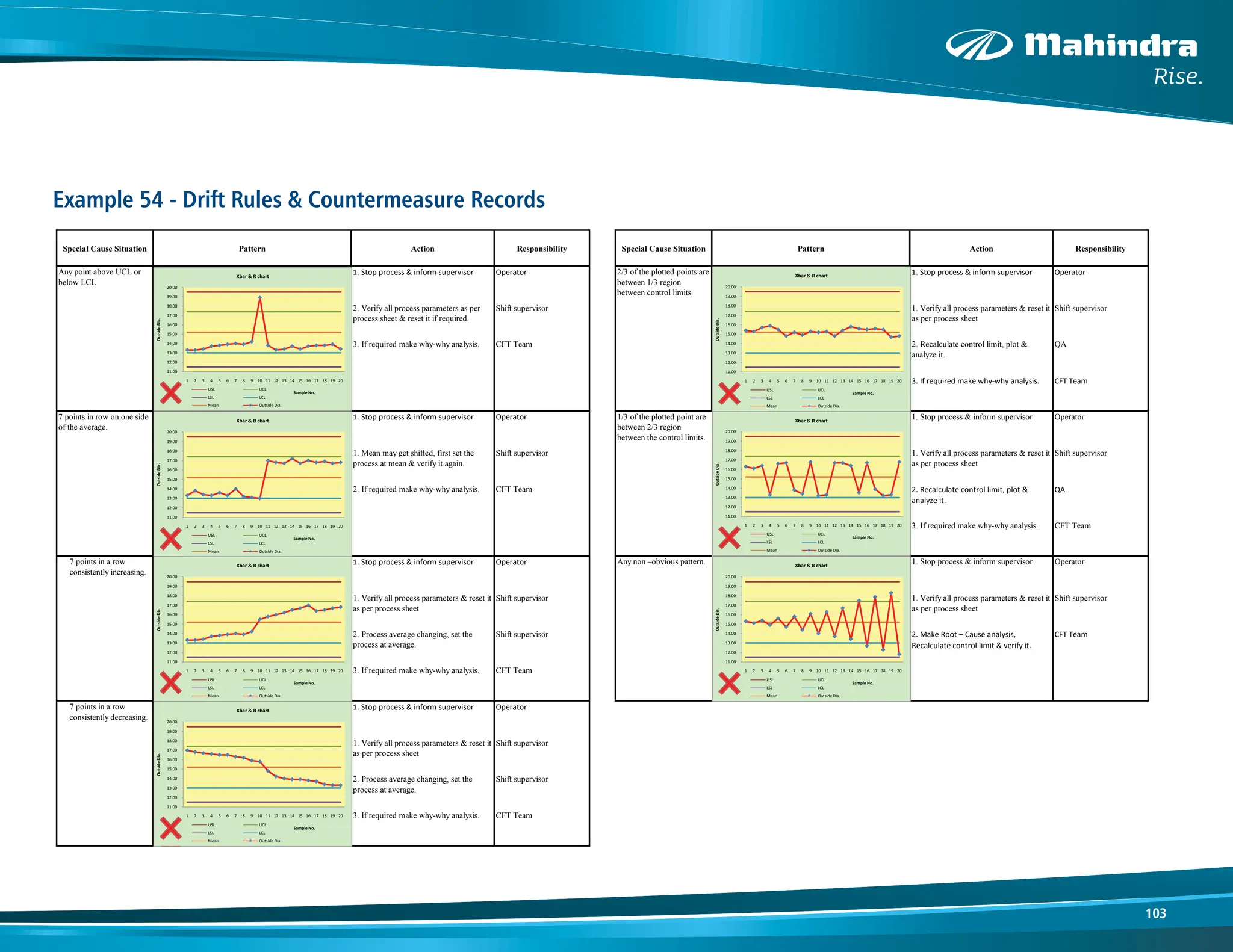

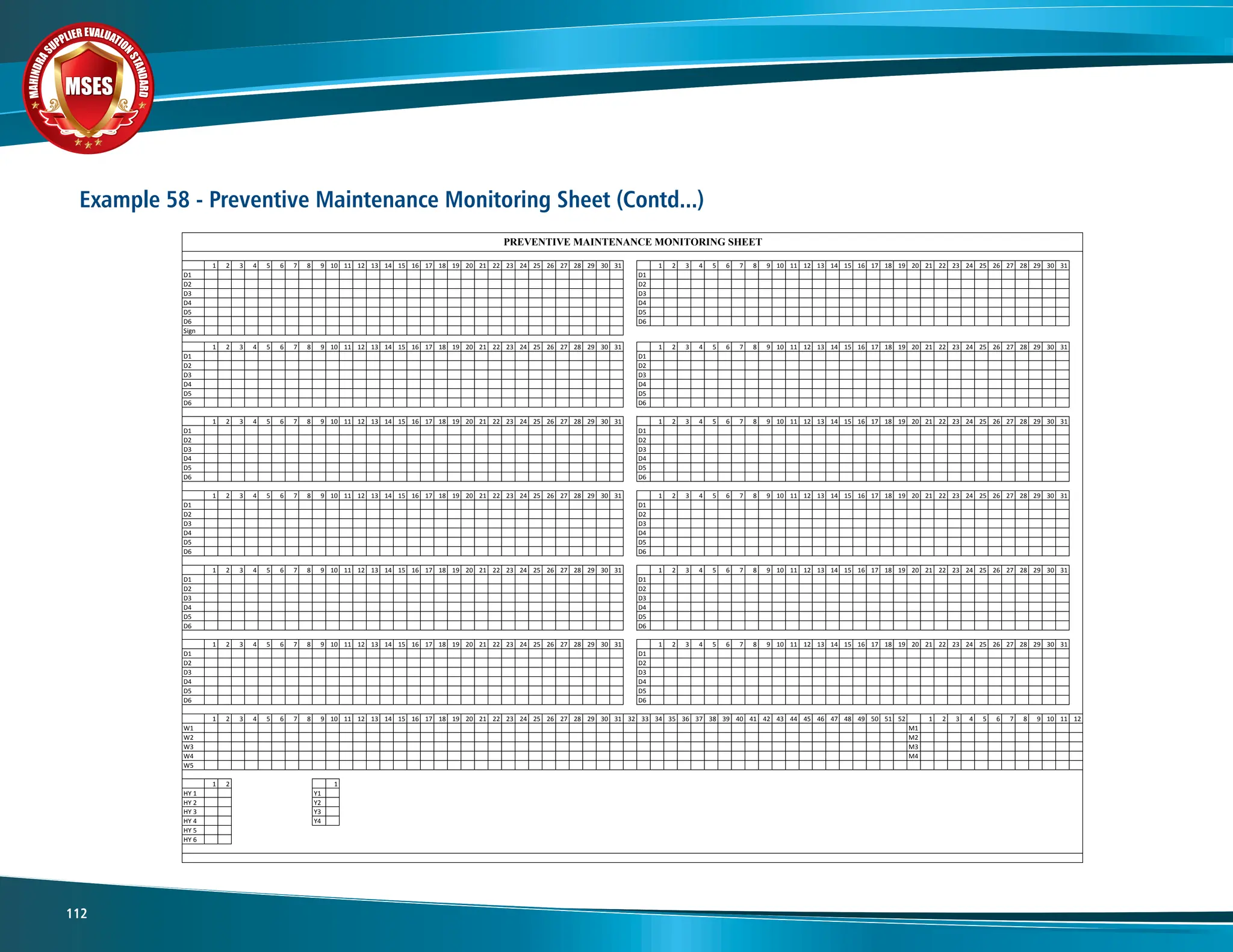

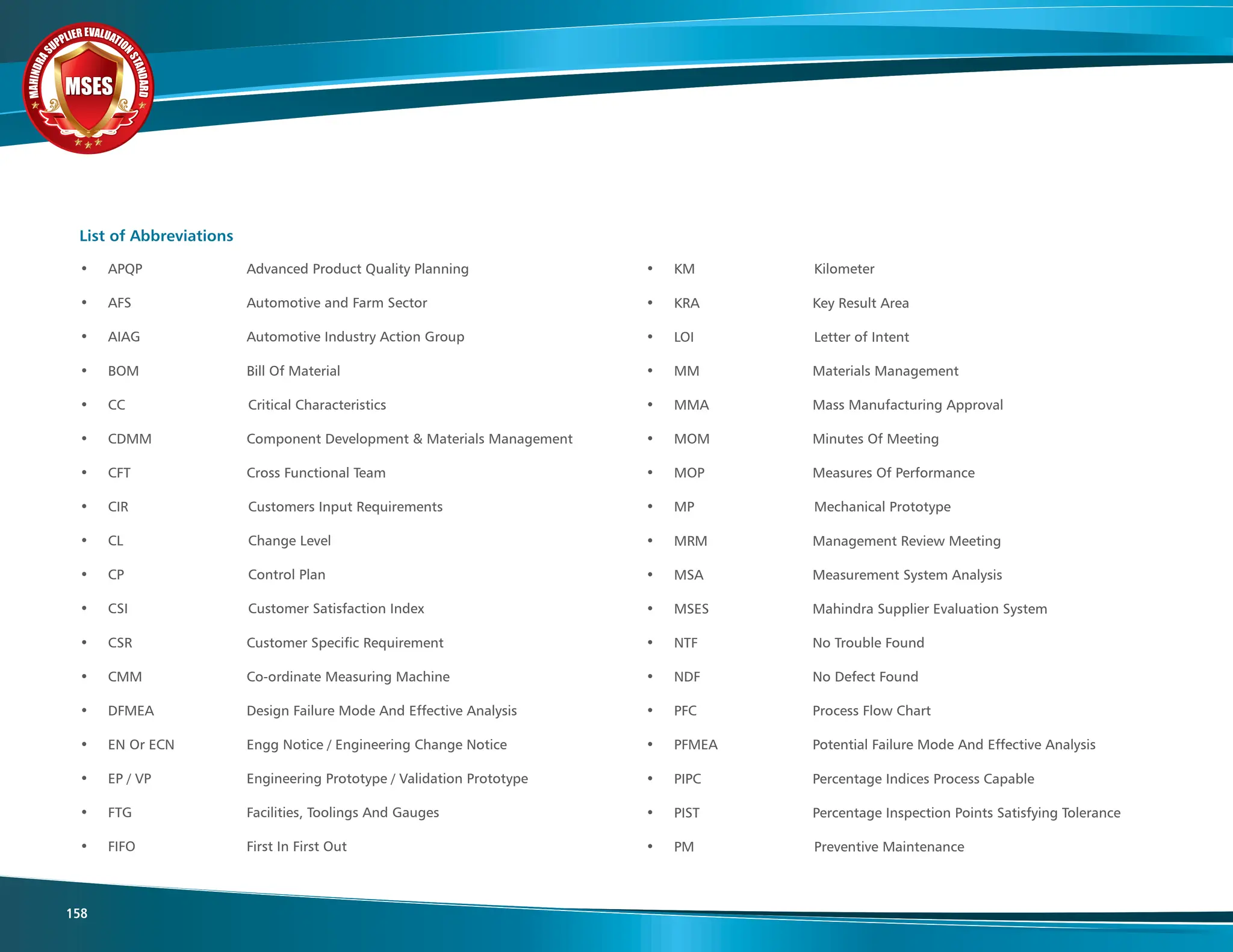

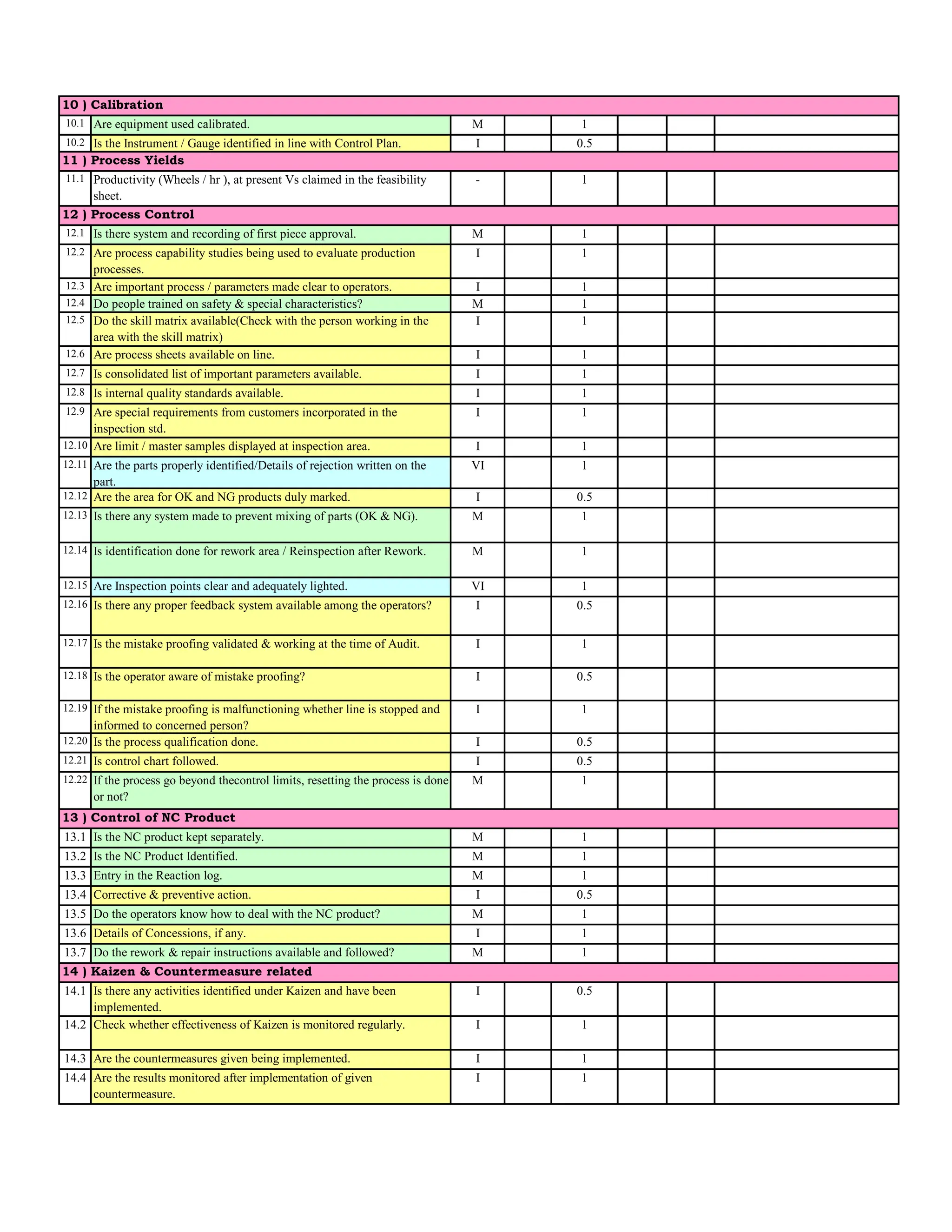

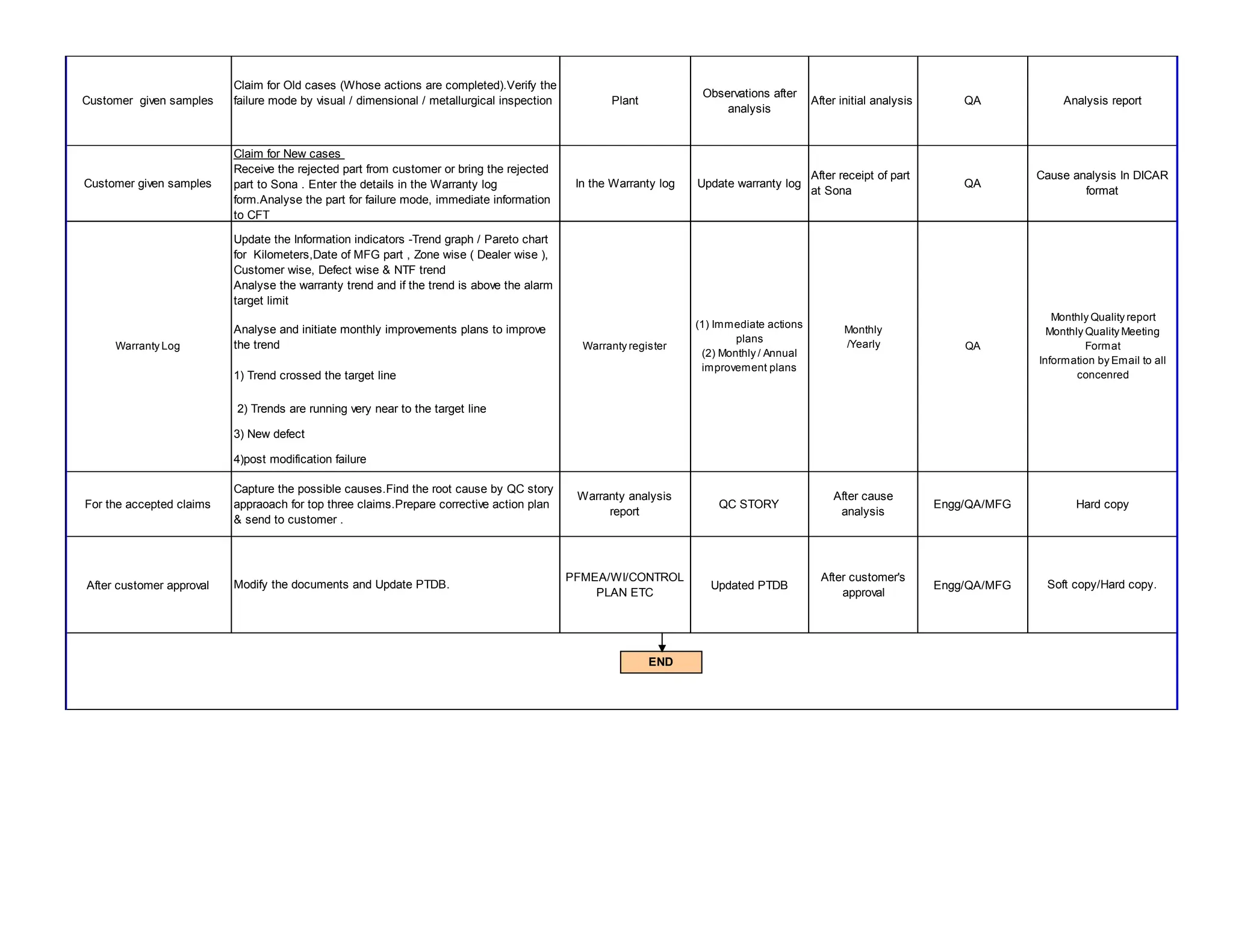

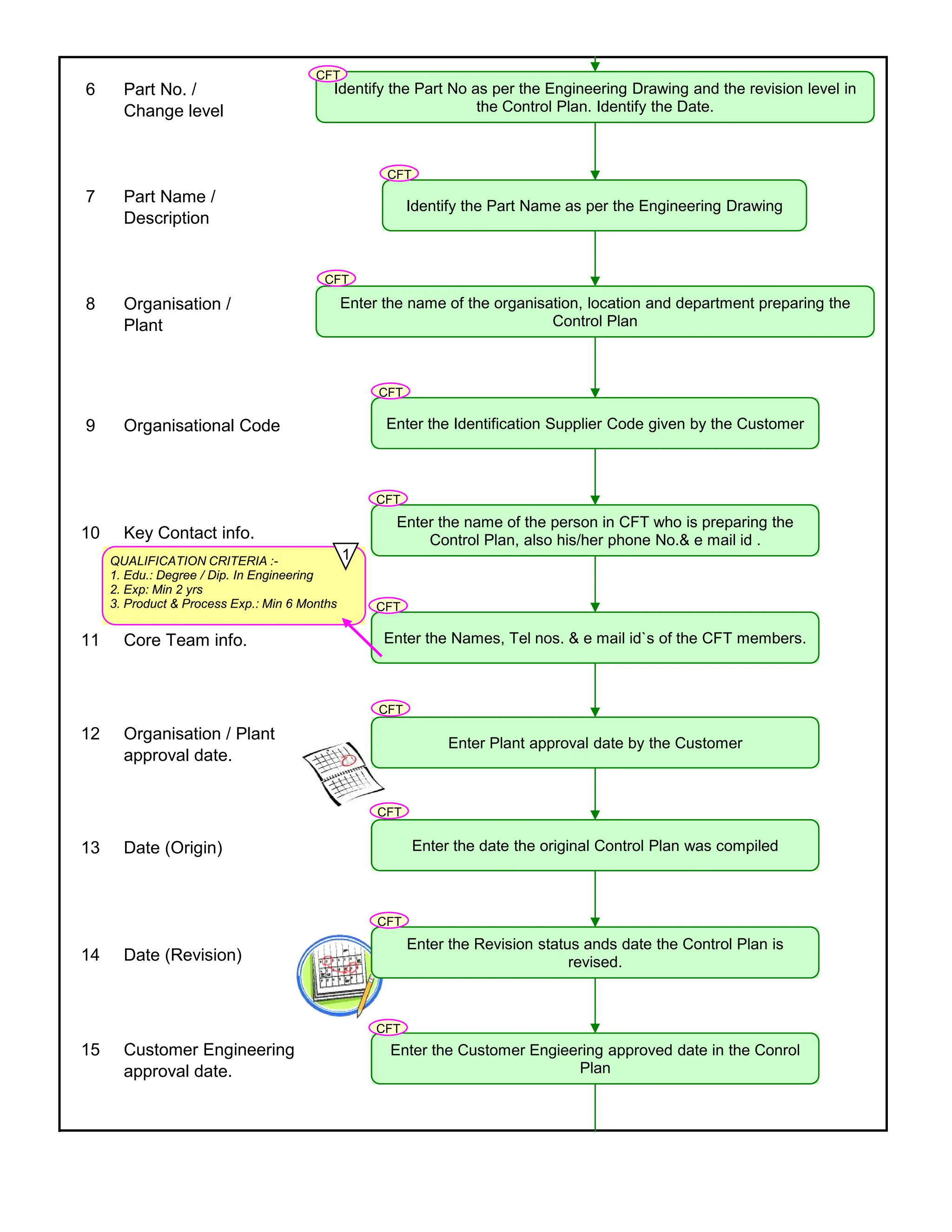

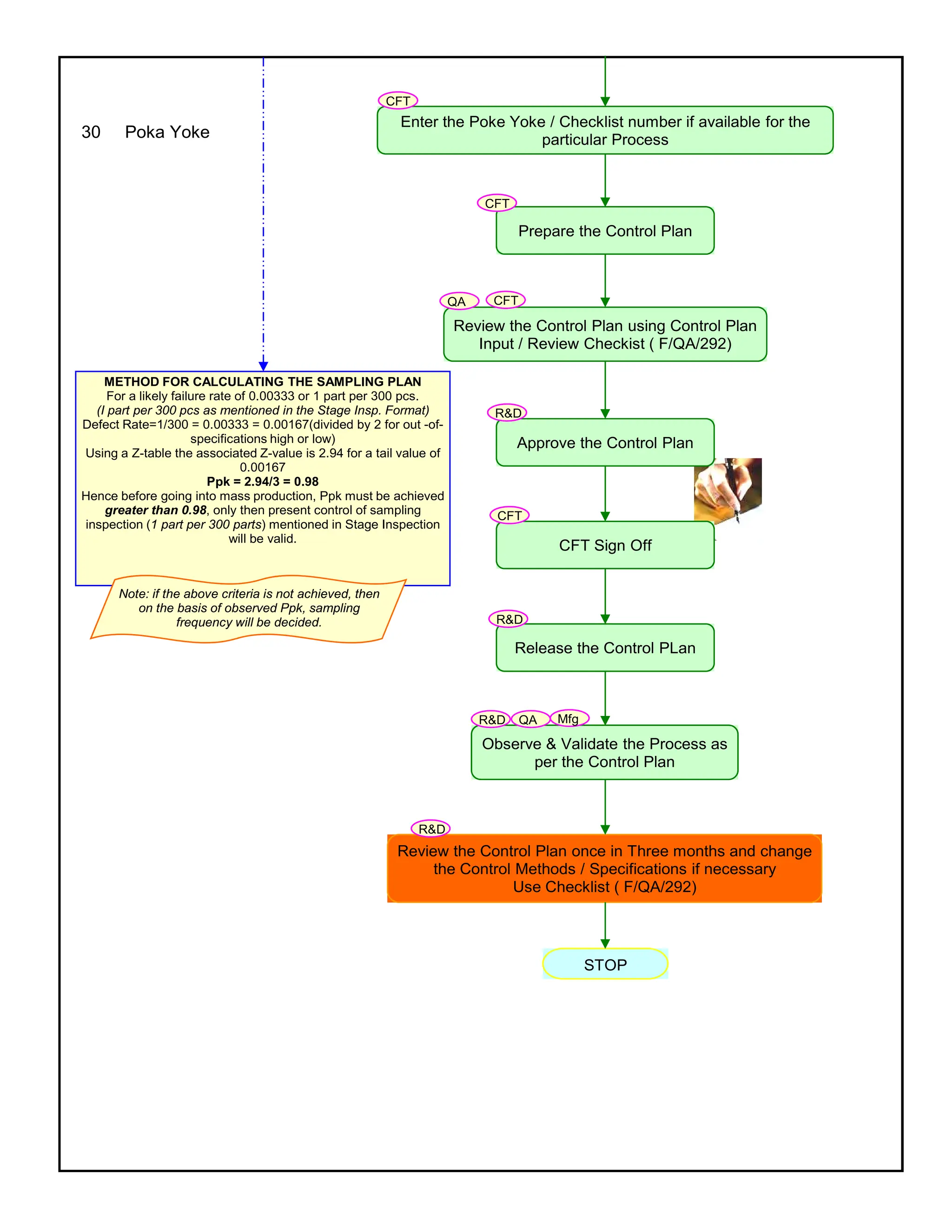

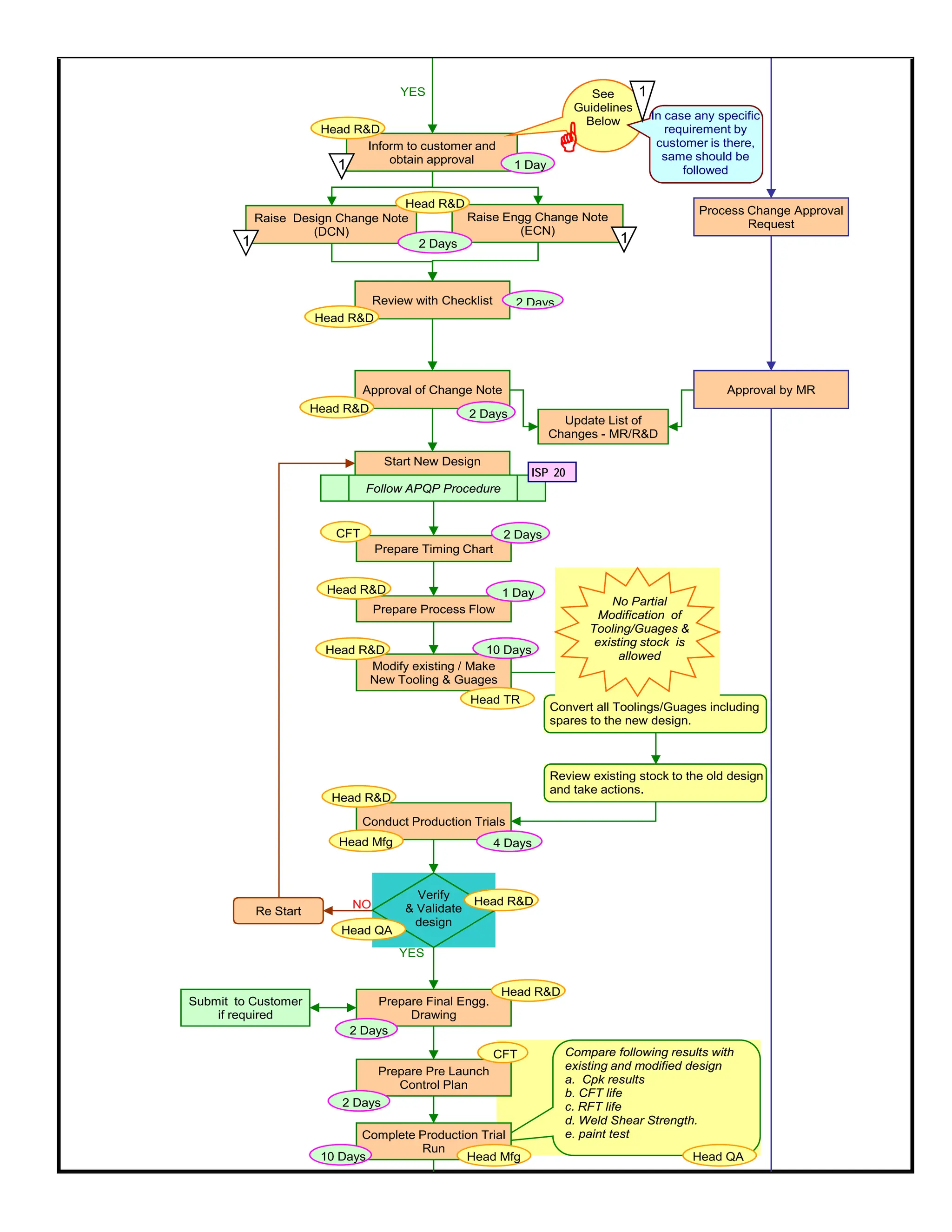

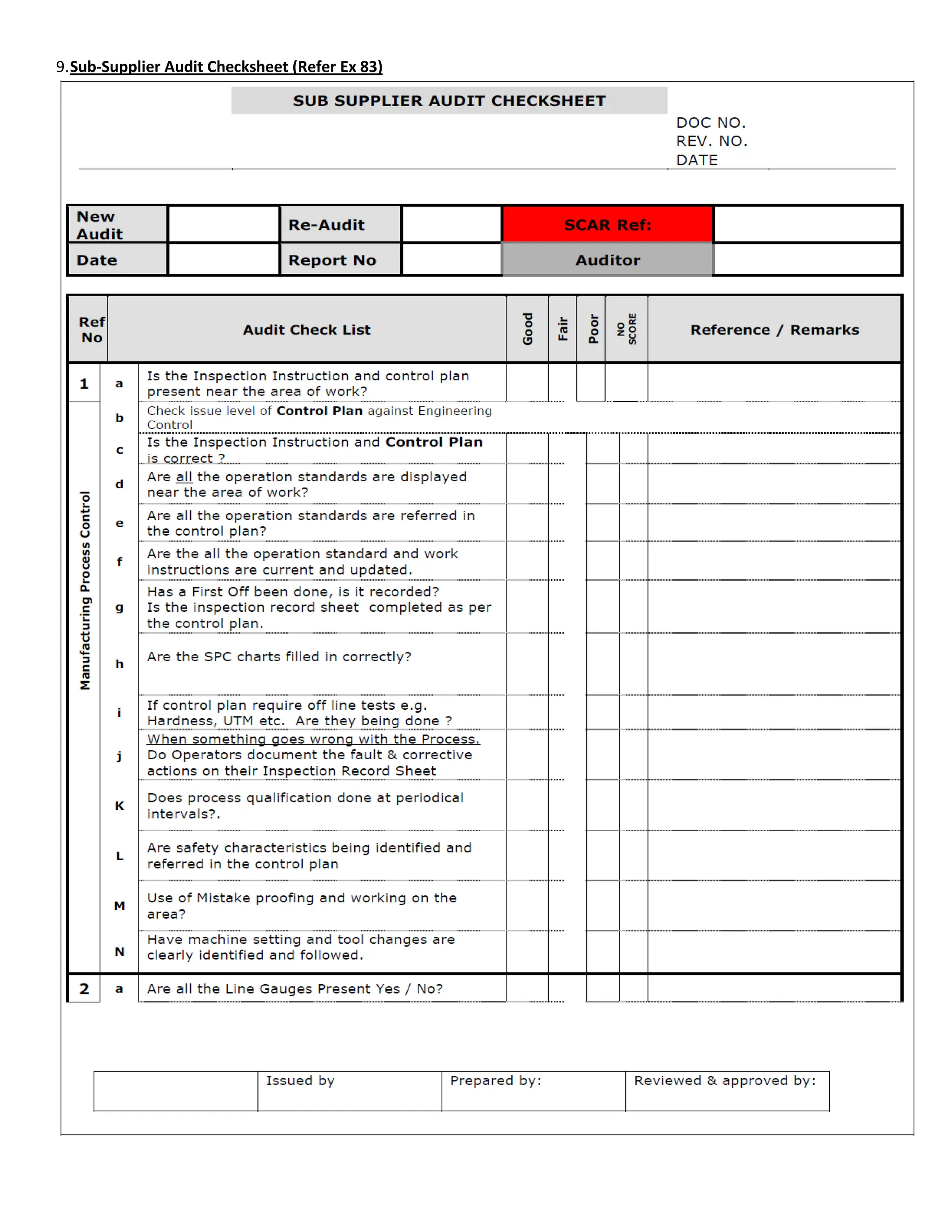

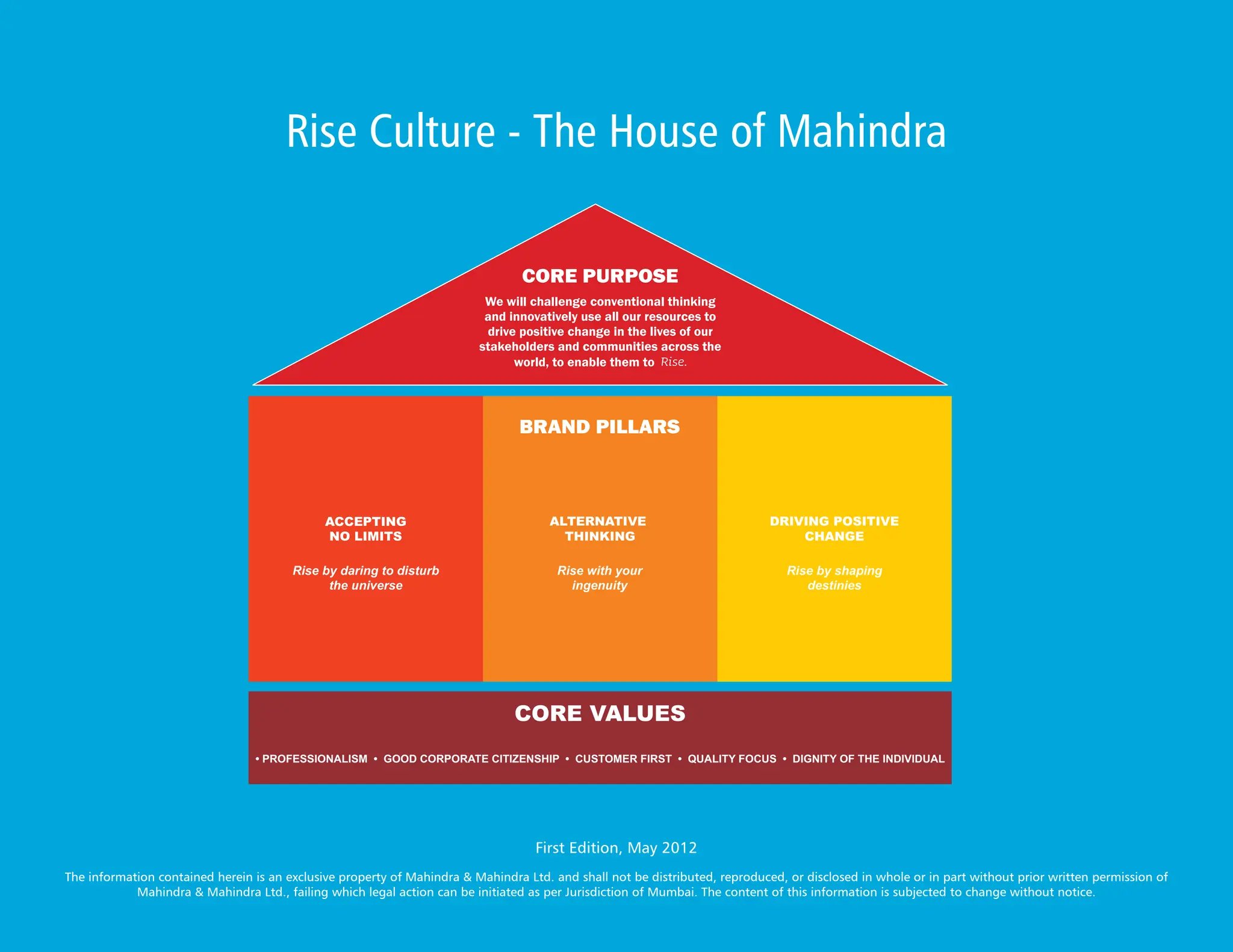

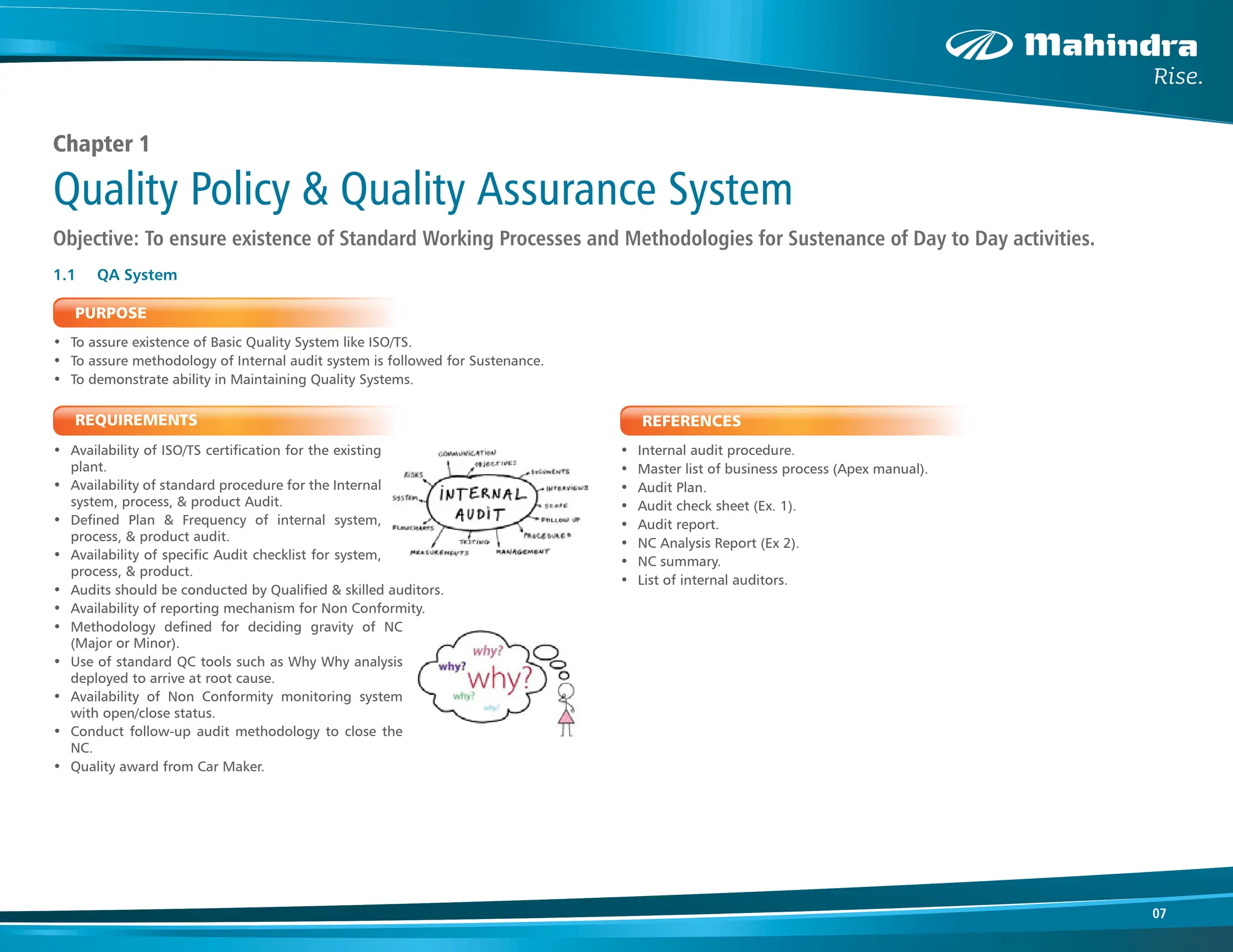

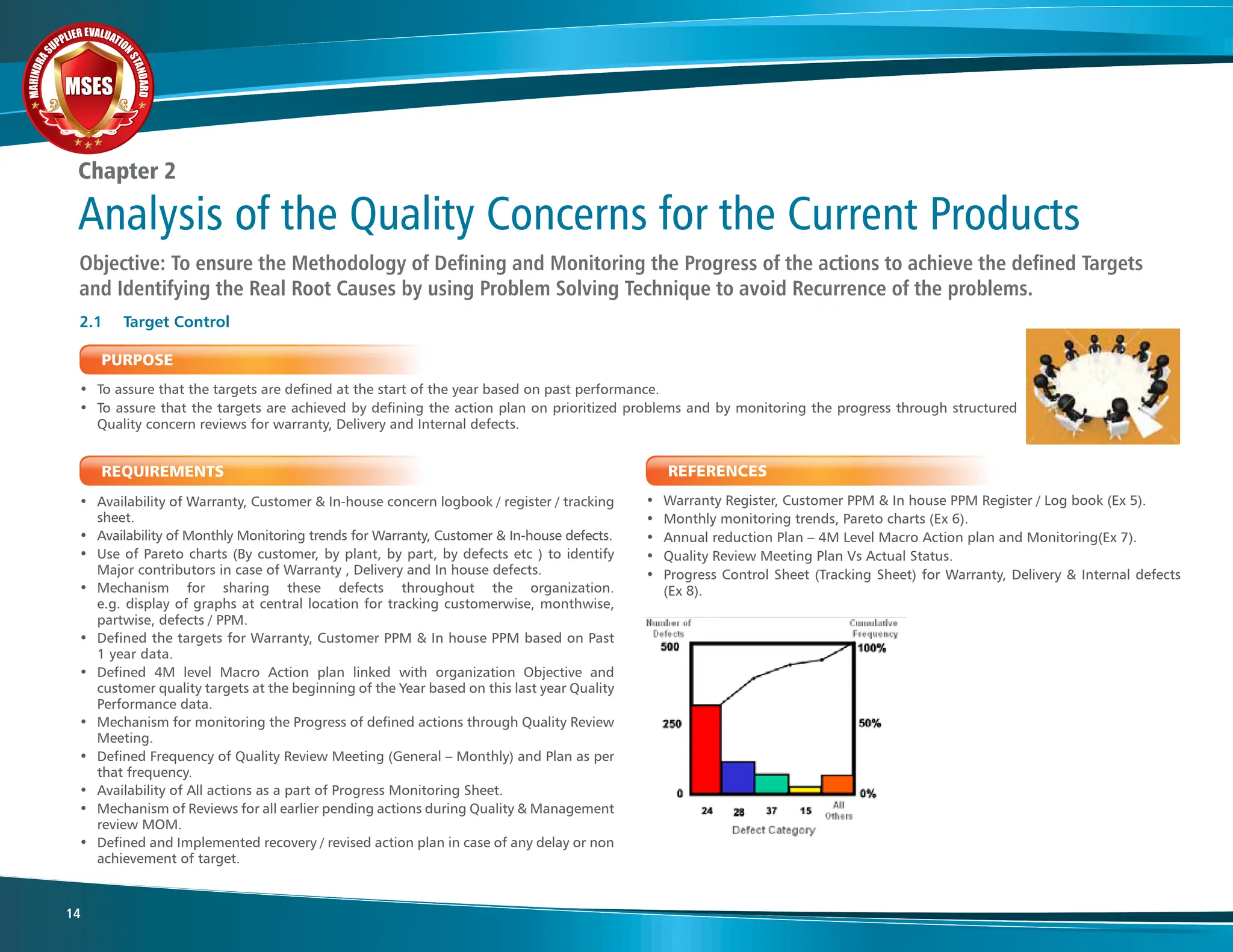

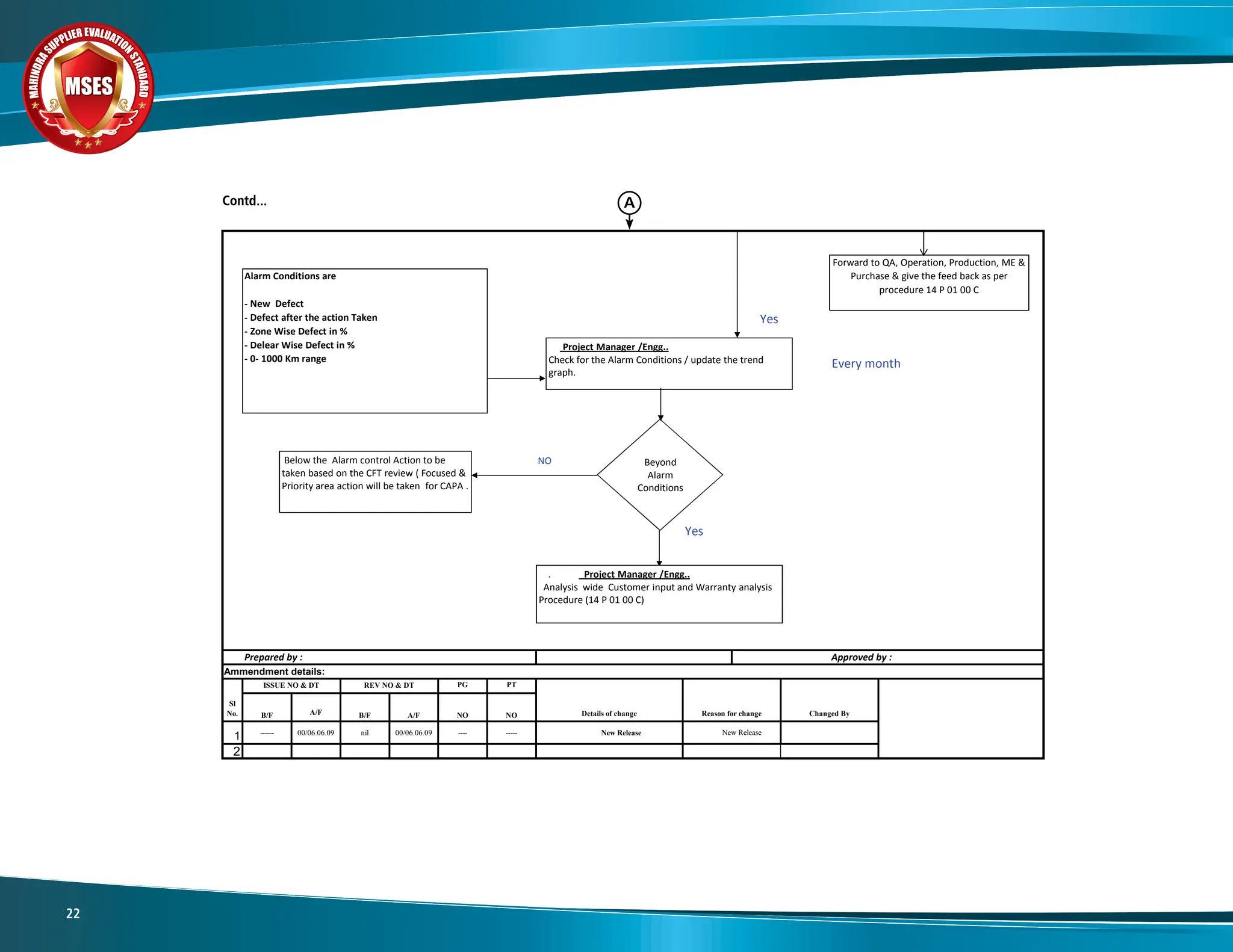

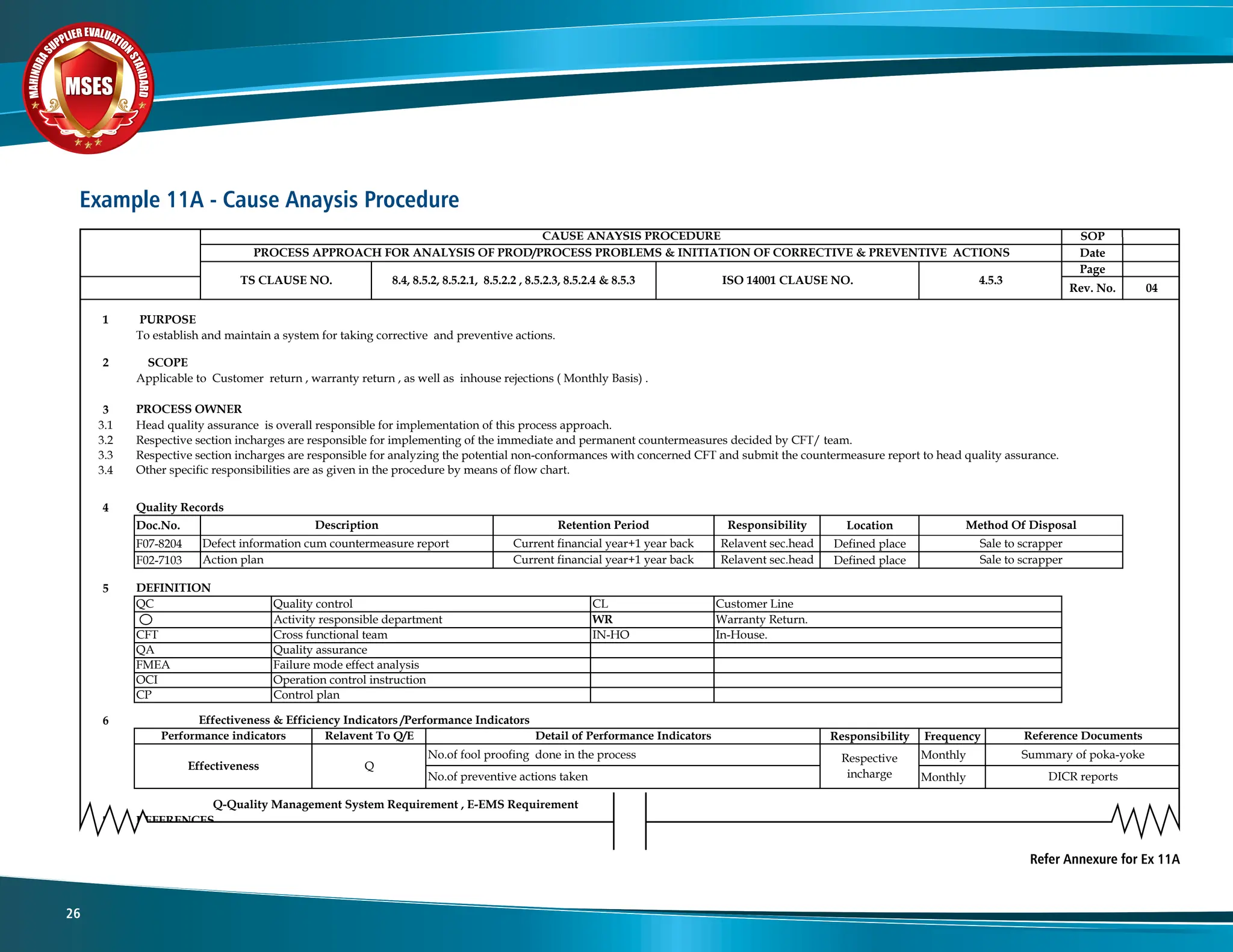

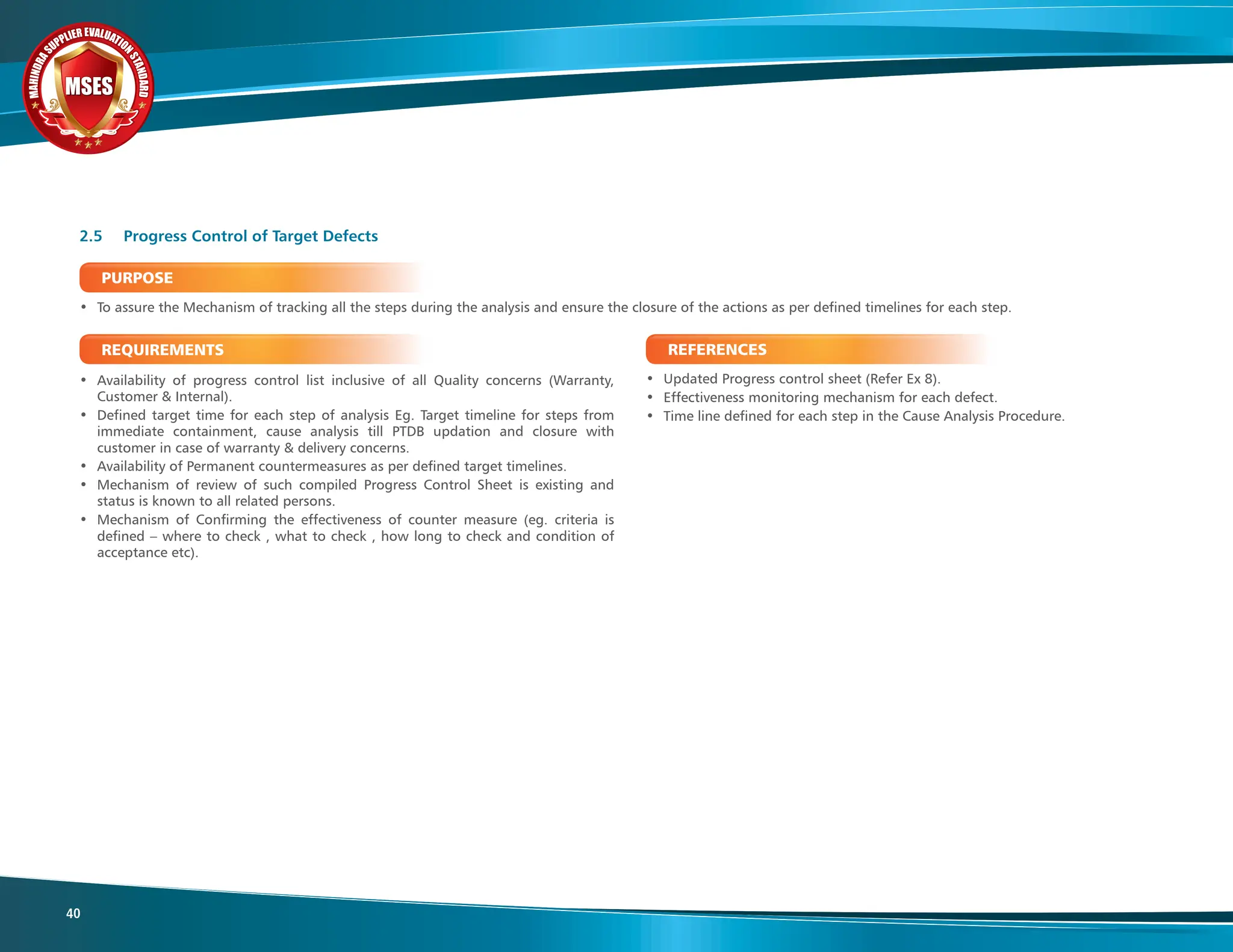

Sr. no. DO'S DON’T

Always ensure the Crorugated cap on the Plastic Socket Do not take without cap part for assembly

hmaoSaa Qyaana do kI plaasTIk saa^koT pr kaorugaoToD k^p lagaa huAa hO. kop ko ibanaa paT- AsaoMbaila ko ilayoa na lao.

Ensure perfect guide when lock set is placed in the fixture.

Do not clamp the assembly if the lock set is not located in the stearing

column

laa^k saoT kao iFkscar mao rKnao sao phlao ]saka gaa[D saih hO yaa naih yao

jaaca lao.

yaid laa^k saoT sToirnga ka^lama mao laaokoT naih hao rha tao Asaomabaila na kro.

Recommendation Sheet for Lock Set

This will Damage /bend the terminals of the plastic socket causing electrical assembly failure.

1

RISK

2

yah plaasTIk saa^koT ko Trimanala kao baoMD yaa D^maoja krgaa ijasasao [laokT/Ikla AsaoMblaI nahI haogaI .

Locking Screws

Location for

Stearing lock

assly

During Handling always keep the lock set in this position

Do not place the parts at any other position ( the terminals may touch

the floor)

laa^k saoT kao [stmaala krto samaya inacao idKayao tirkosao hI rKo. paT- kao ikisaBaI AaoOr paoJaISana maoo na rKo Trimanala jaimana kao laga sakta hoO.

M&M - Stores ( Name,Sign & Date ) M&M -TCF ( Name,Sign & Date )

Approval

3

RISK

[sao la^ca laa^k Aoaor sToirnga ka^lama ko ibaca kaif jyaada [MTrfosa banaogaa ijasasao sToArIMga laa^k Aa^proT nahI haogaa .

RISK

yah plaasTIk saa^koT ko Trimanala kao baoMD yaa D^maoja krgaa ijasasao [laokT/Ikla AsaoMblaI nahI haogaI .

This will creat high interference between Latch lock & stearing column due to which stearing lock will not operate.

This will Damage /bend the terminals of the plastic socket causing electrical assembly failure.

Example 14 - Approved Recommendation Sheet with DO’s & DONT’s](https://image.slidesharecdn.com/msesmanual1-240229040801-aabc191f/75/MSES-Manual-Mahindra-Mahindra-customer-specific-requirements-36-2048.jpg)

![M

A

H

I

N

D

R

A

SUPPLIER EVALUATIO

N

S

T

A

N

D

A

R

D

MSES

MSES

MSES

86

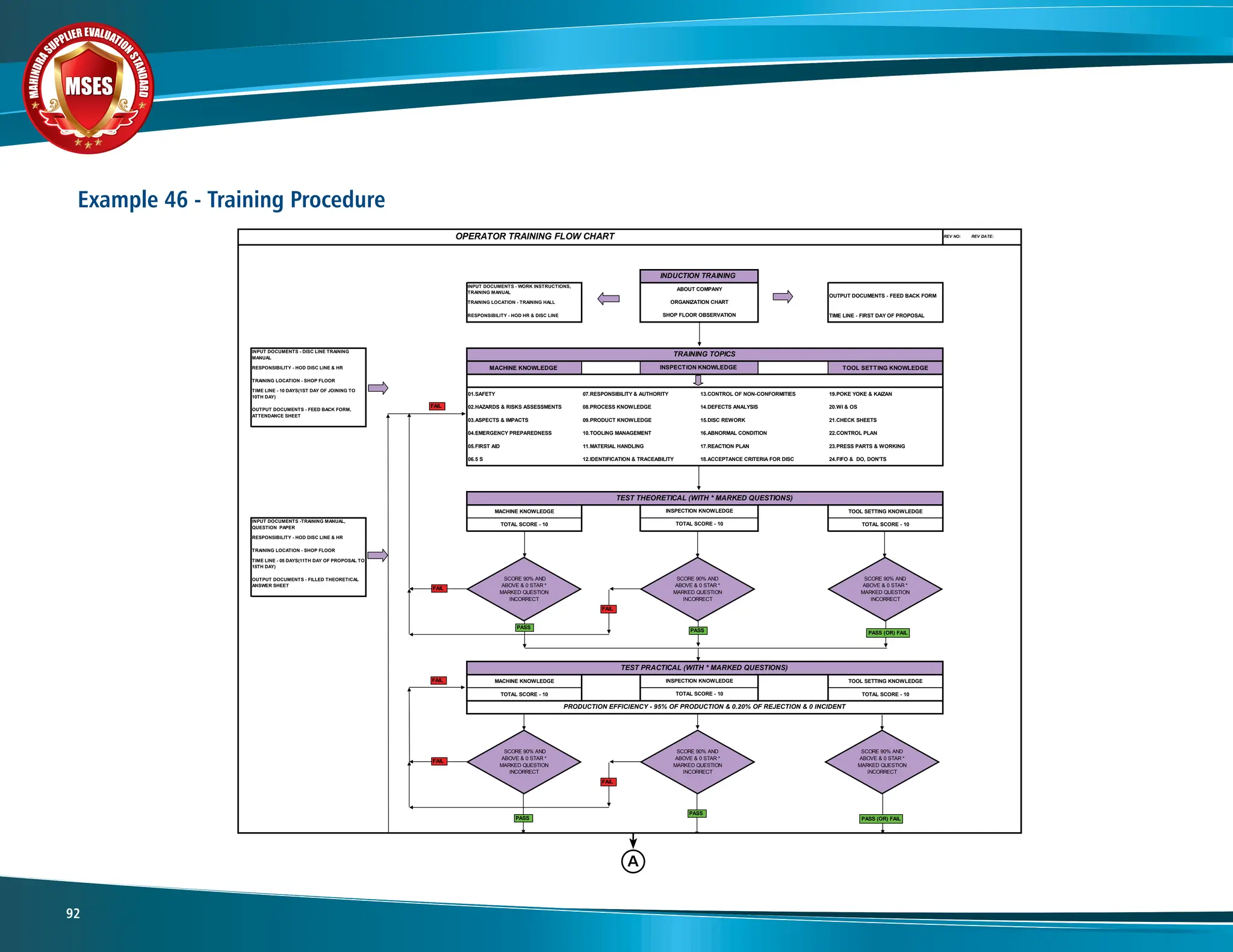

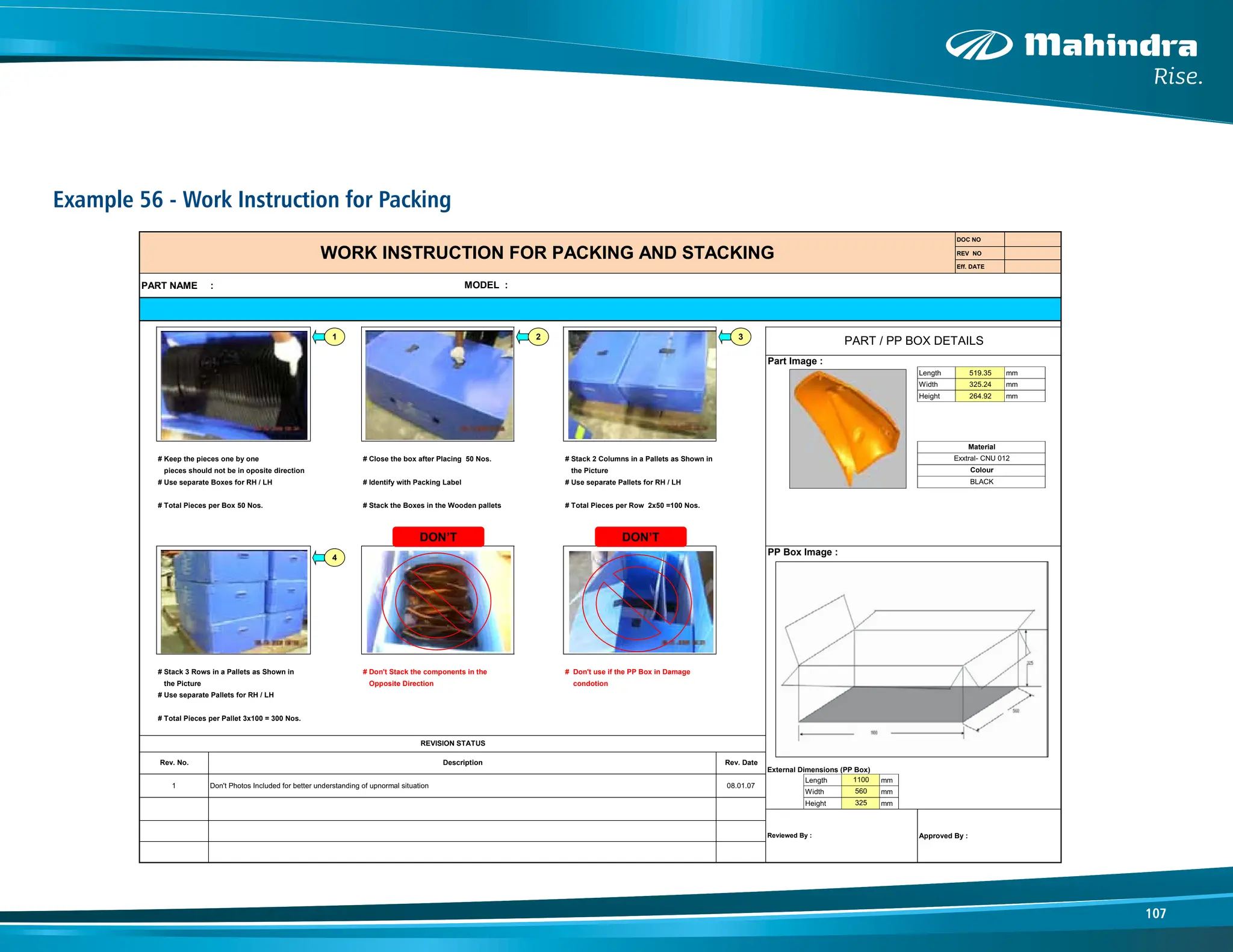

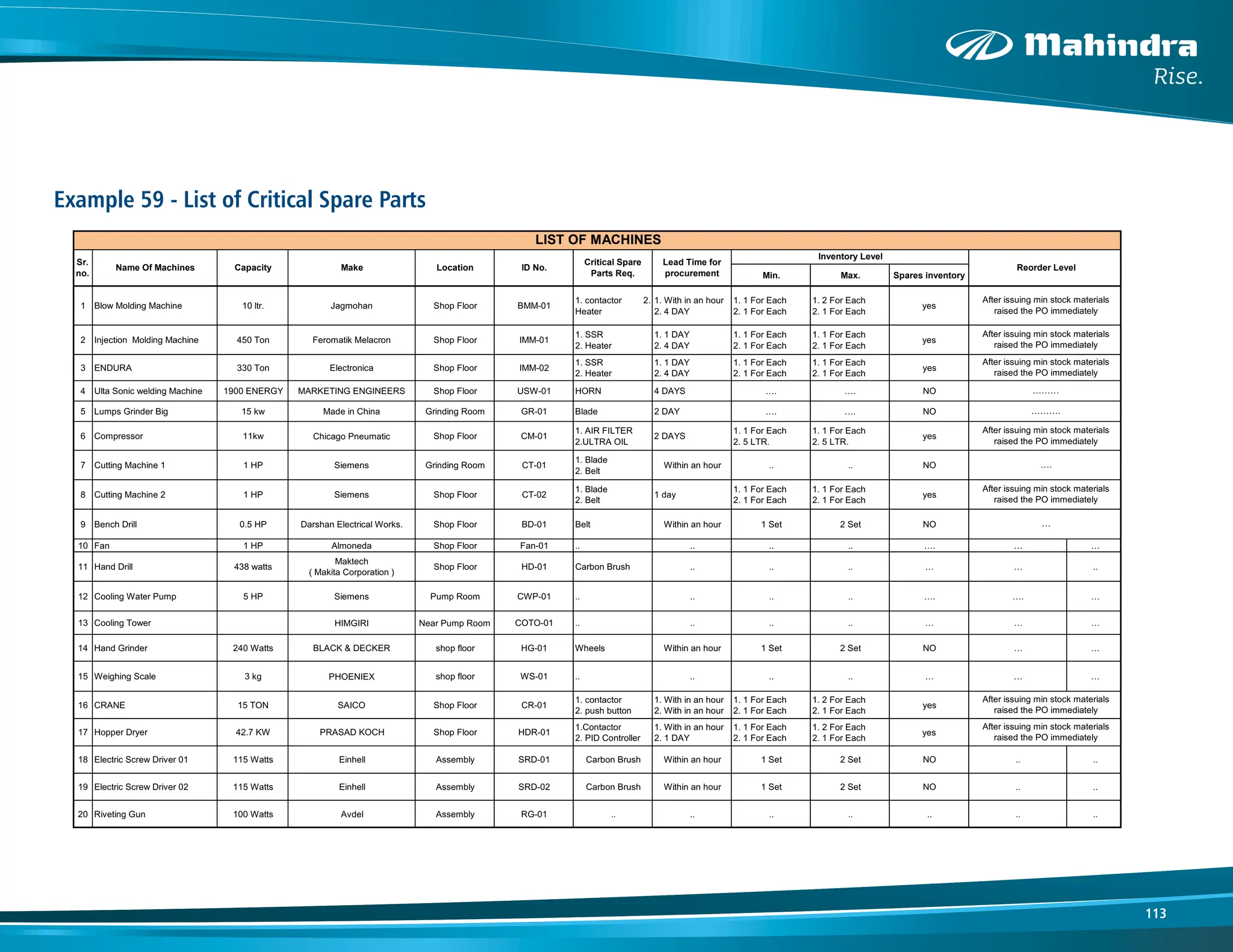

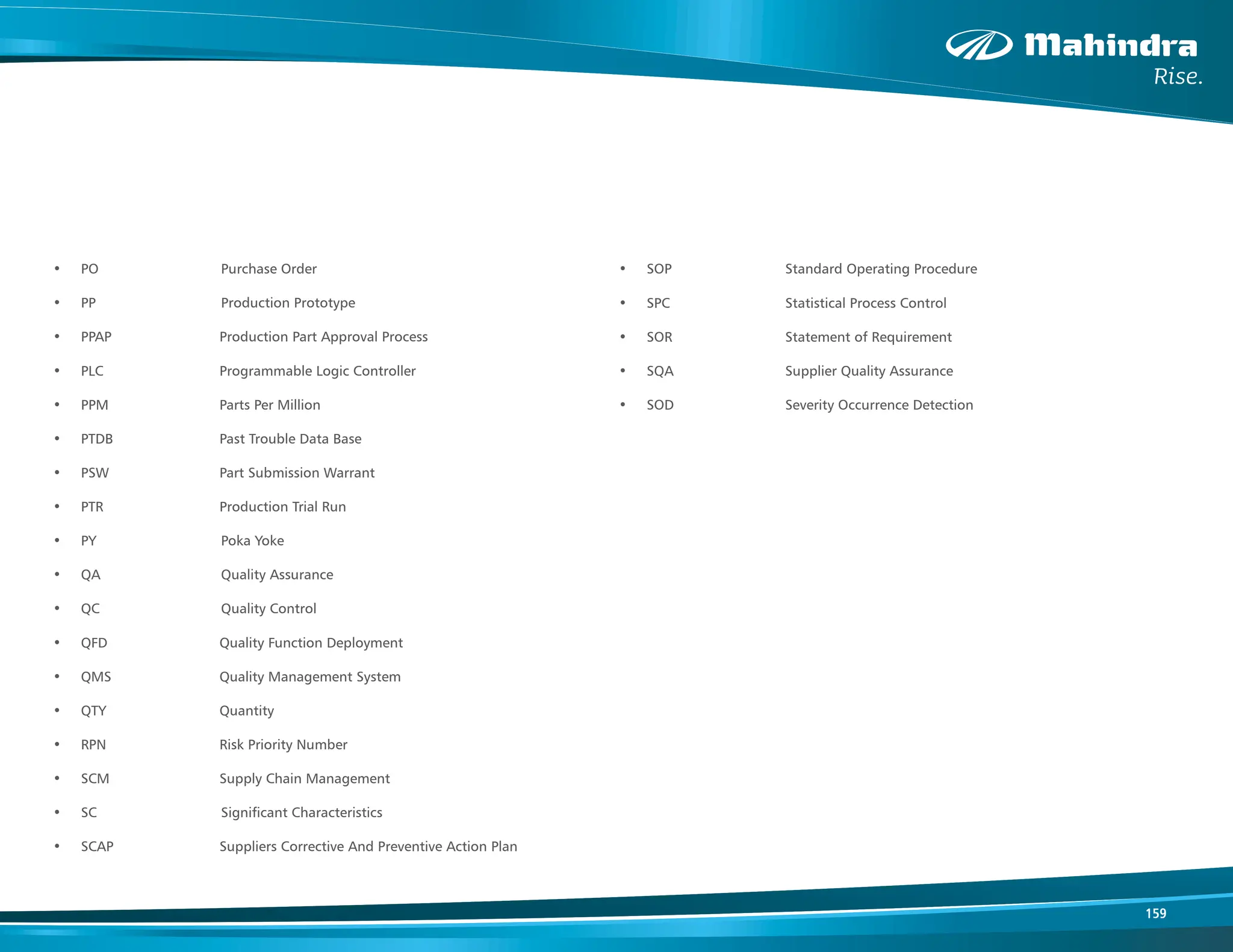

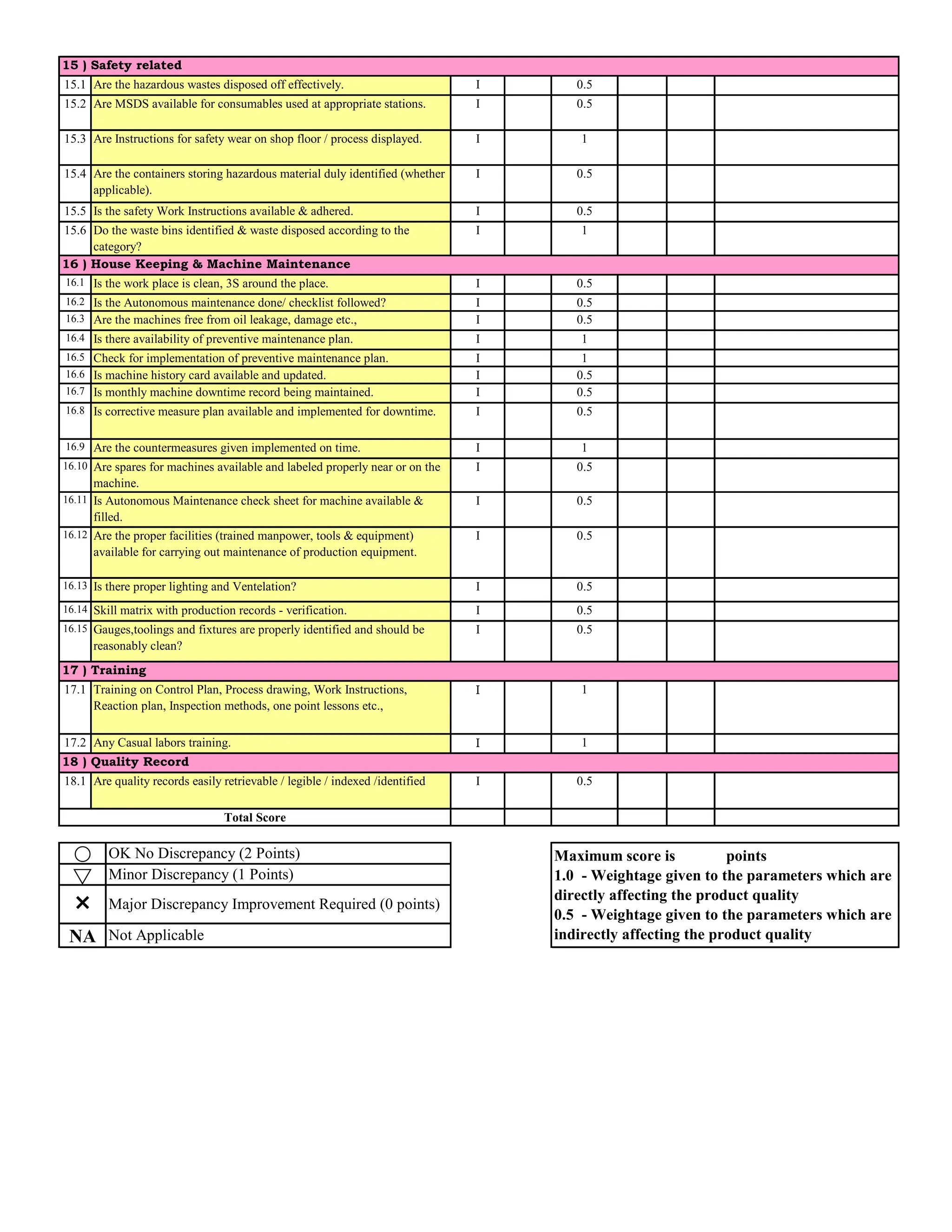

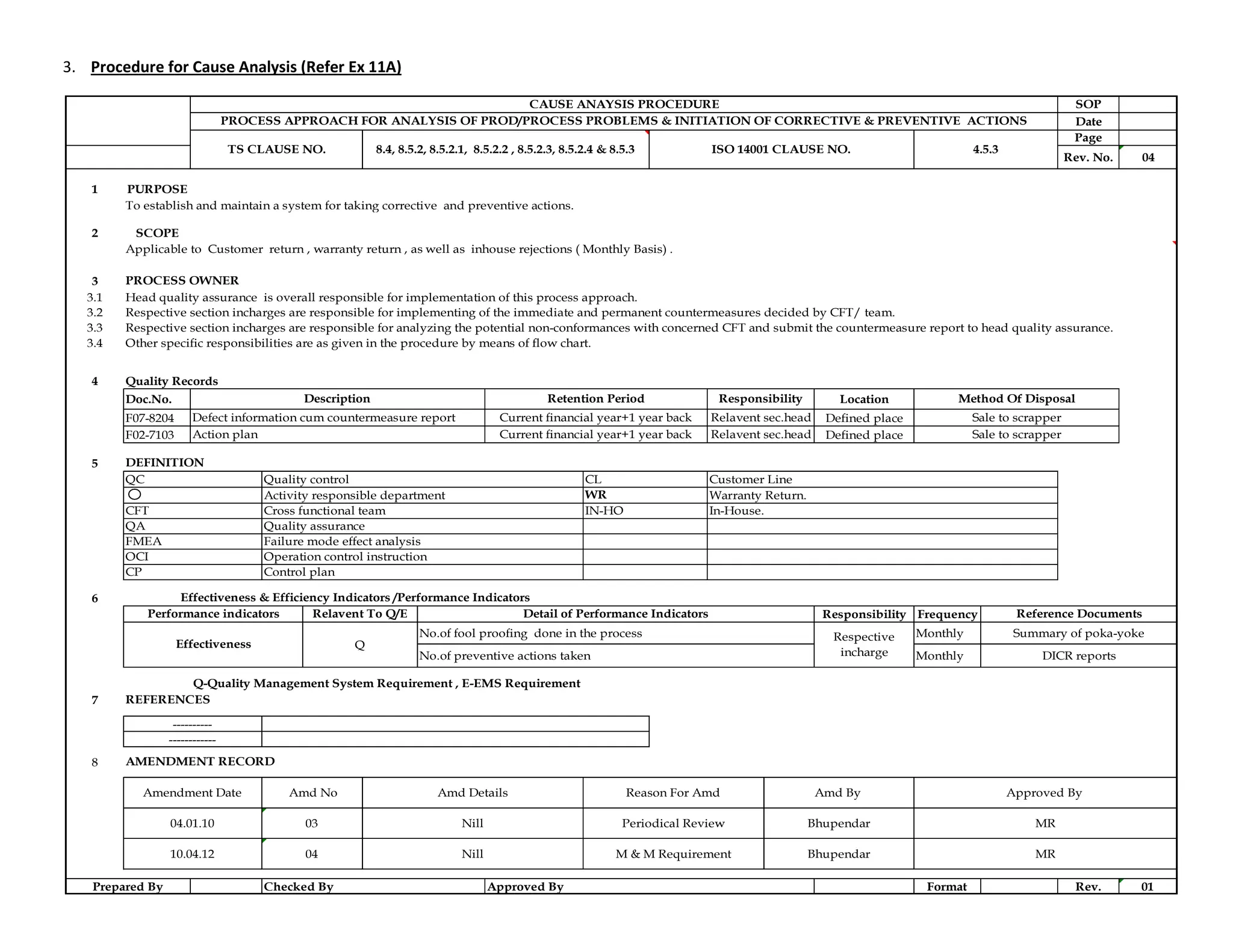

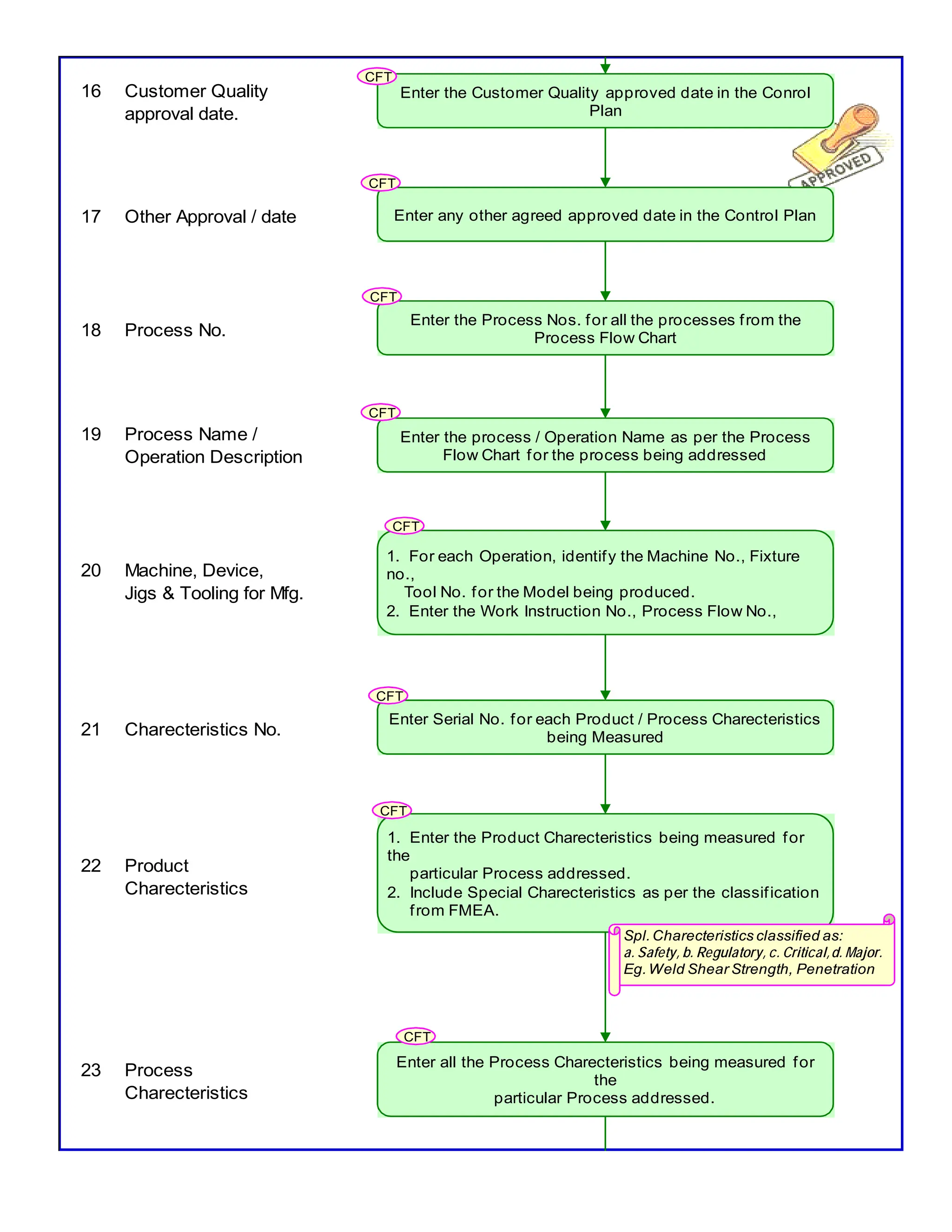

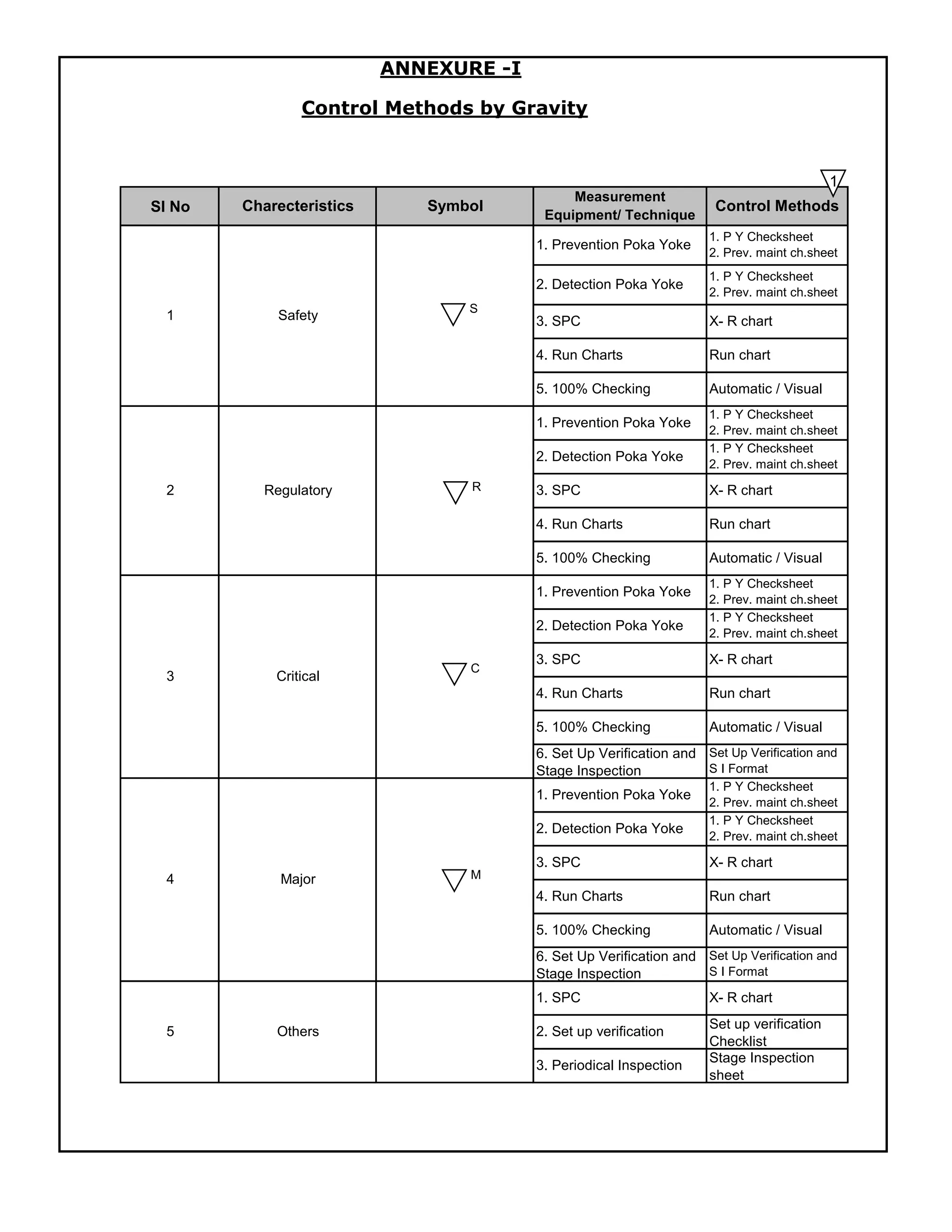

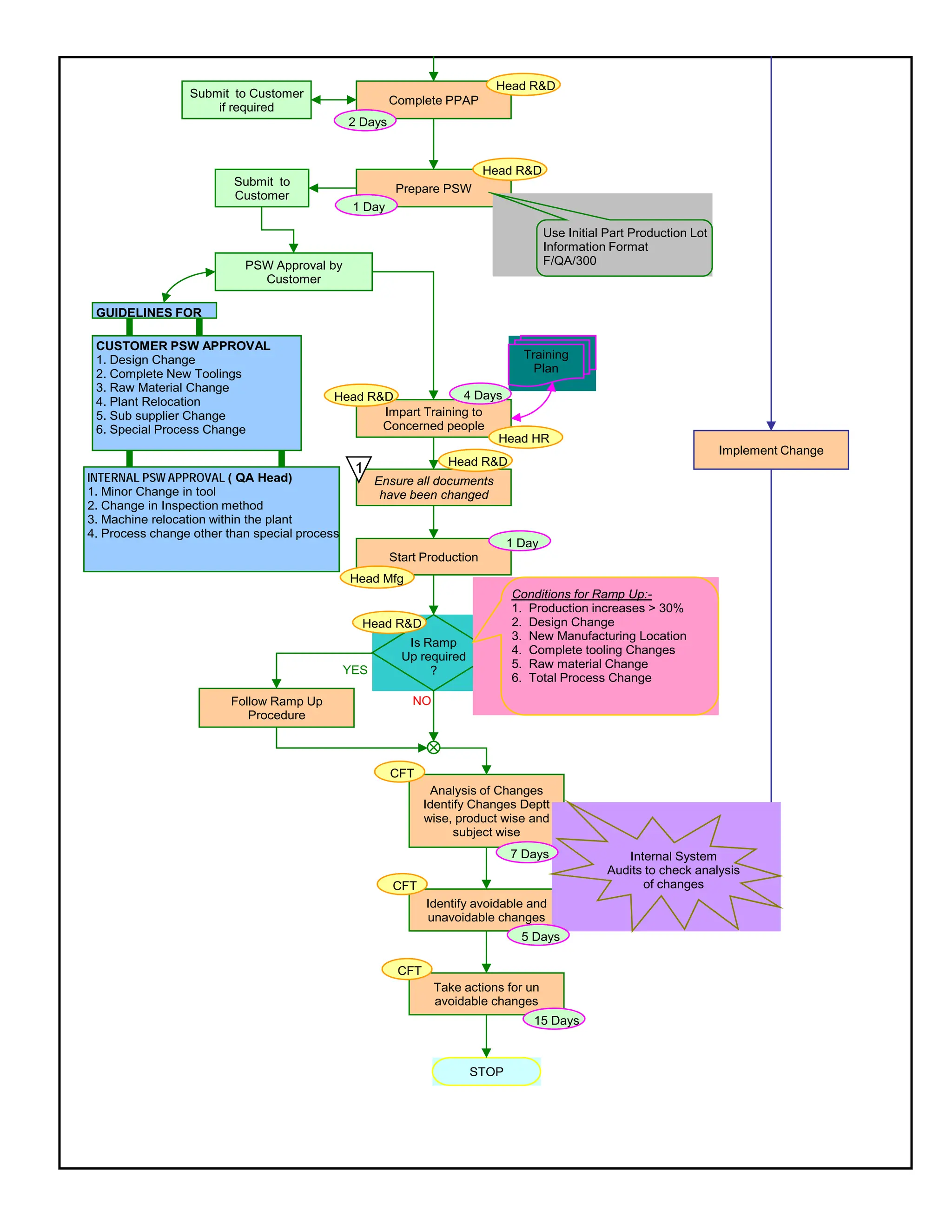

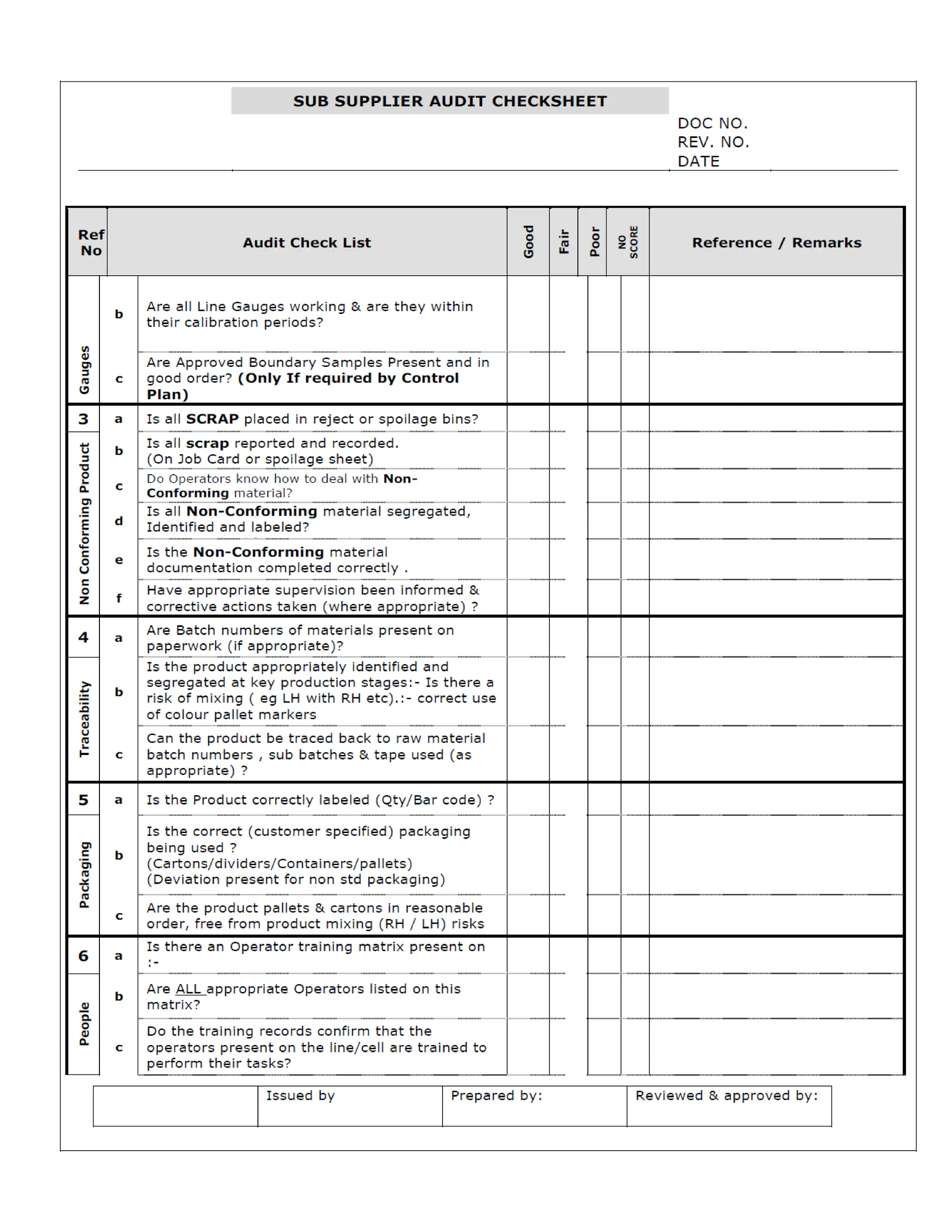

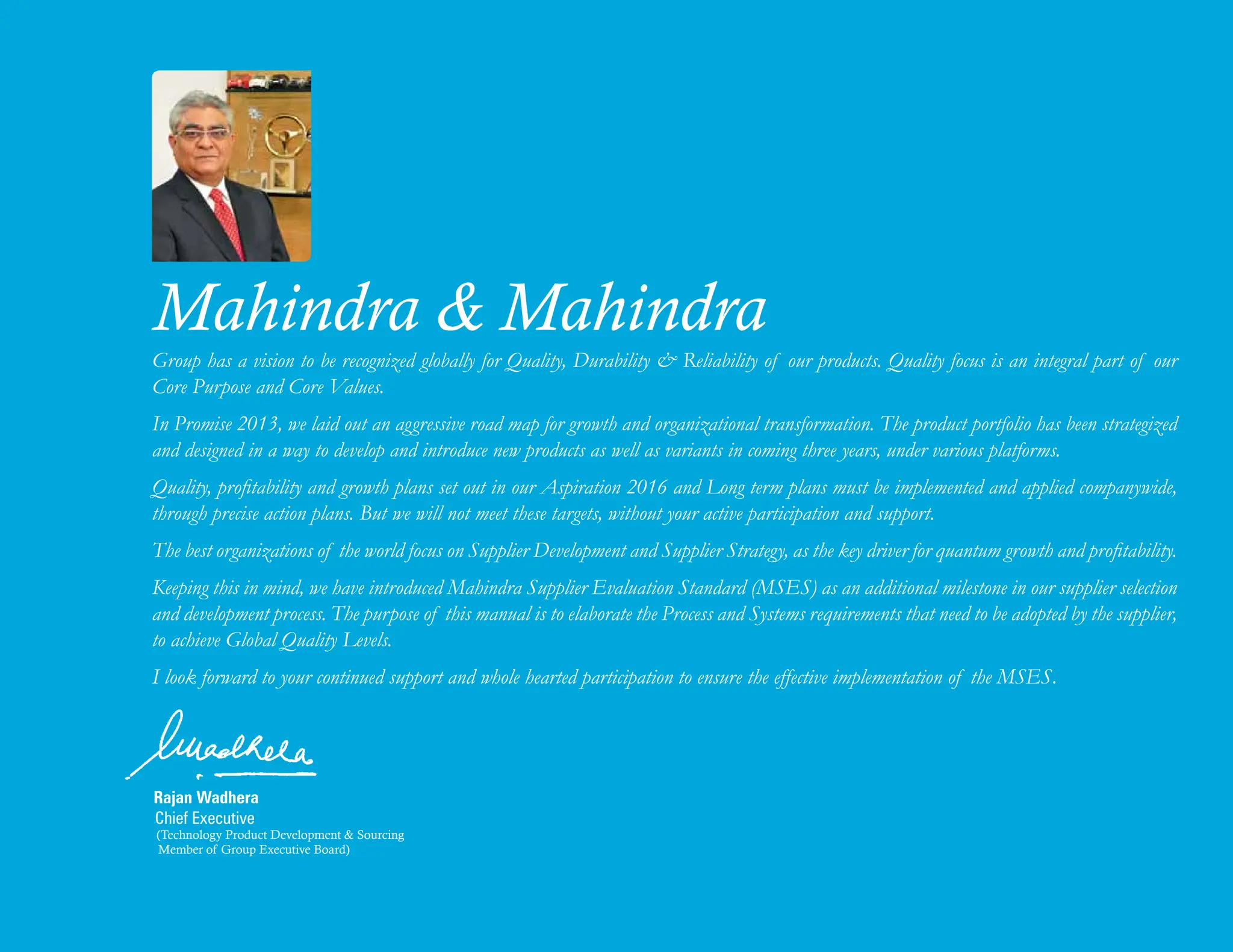

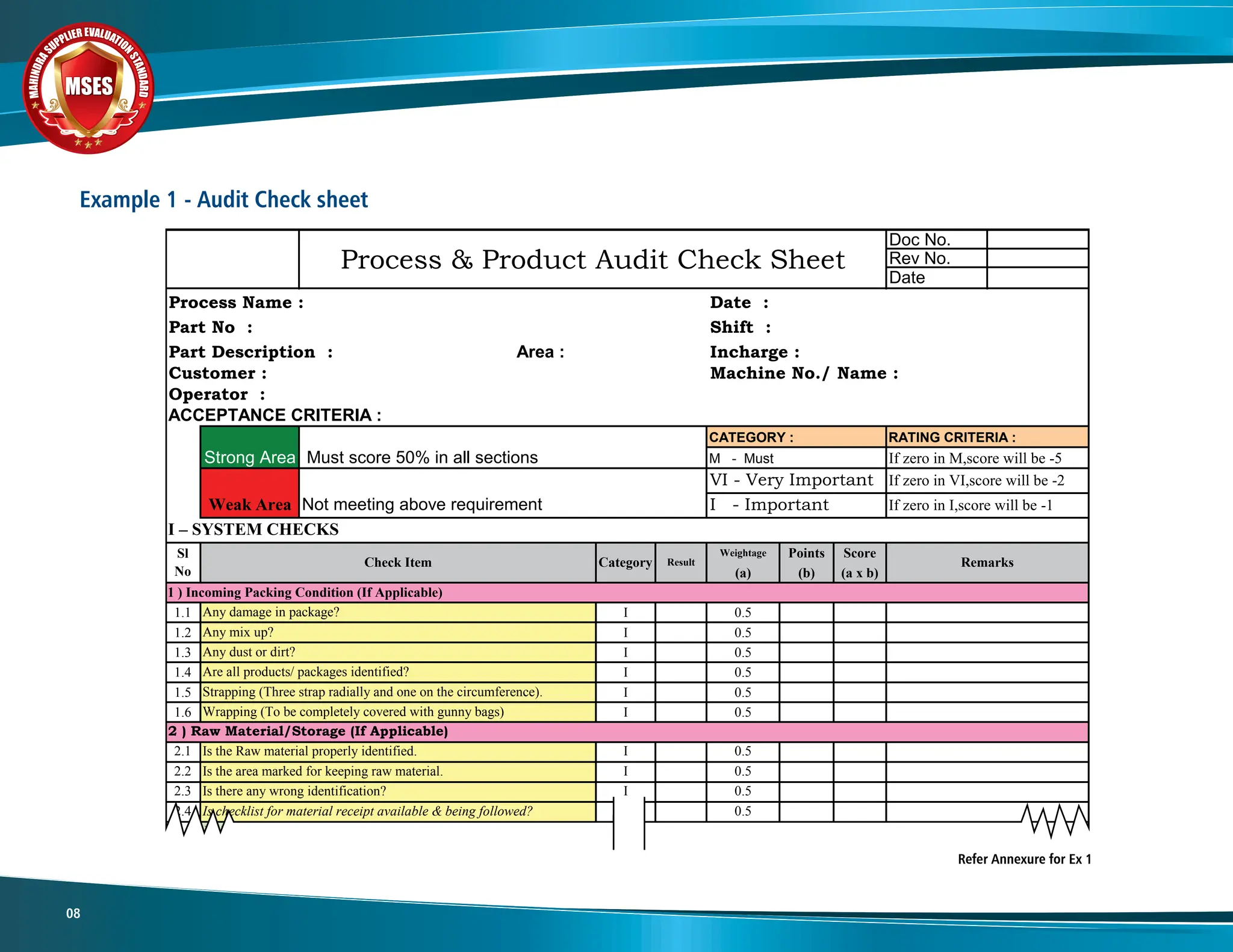

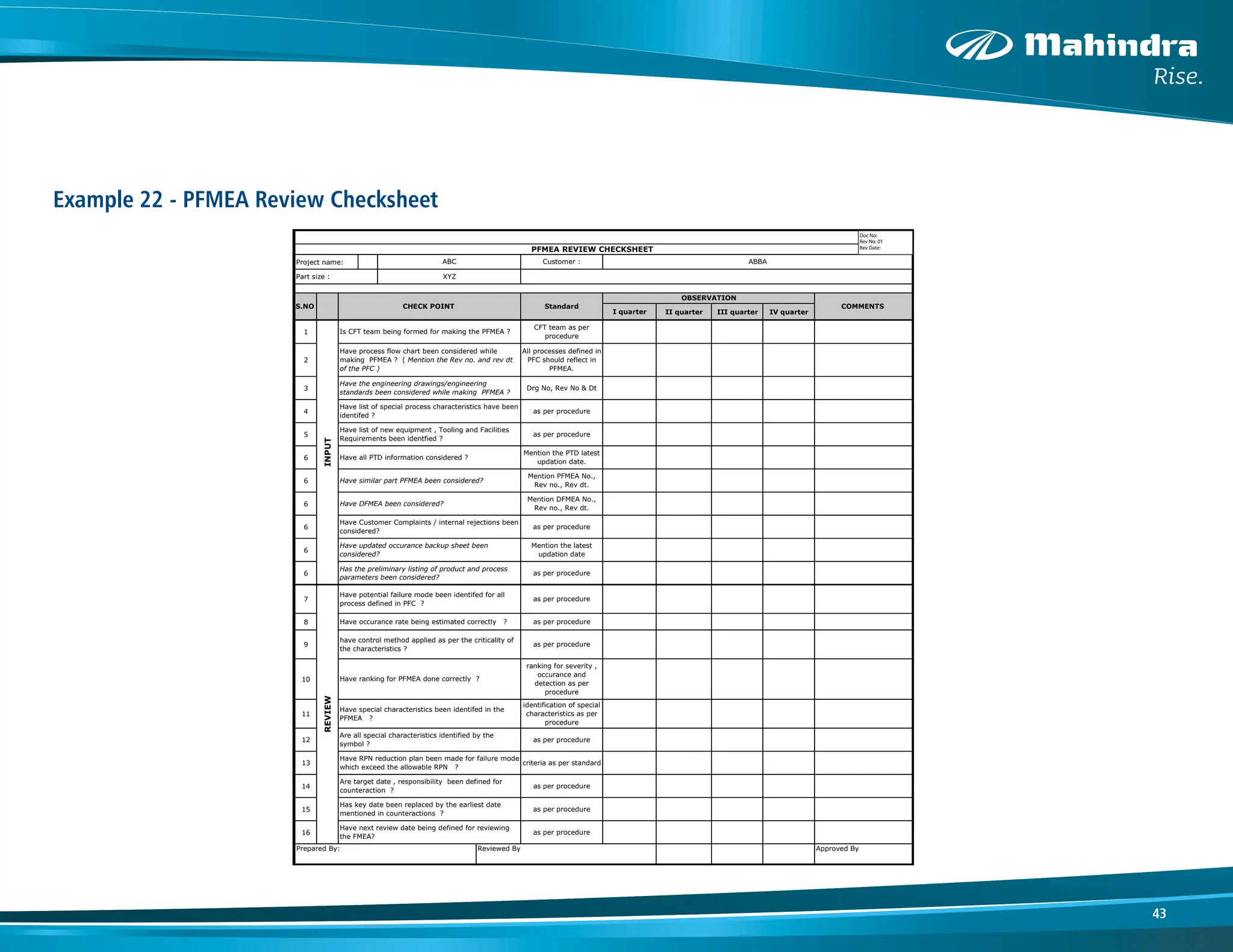

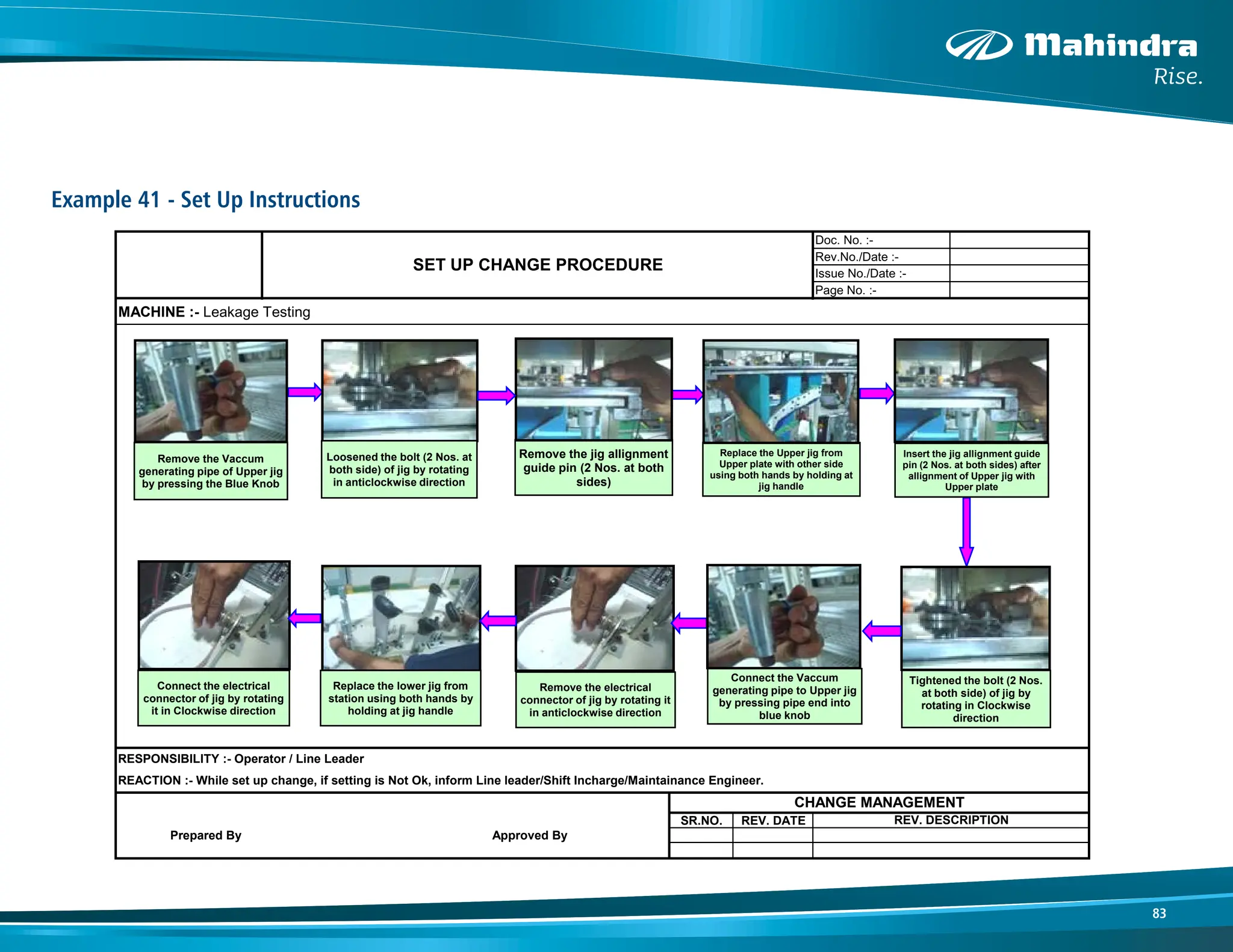

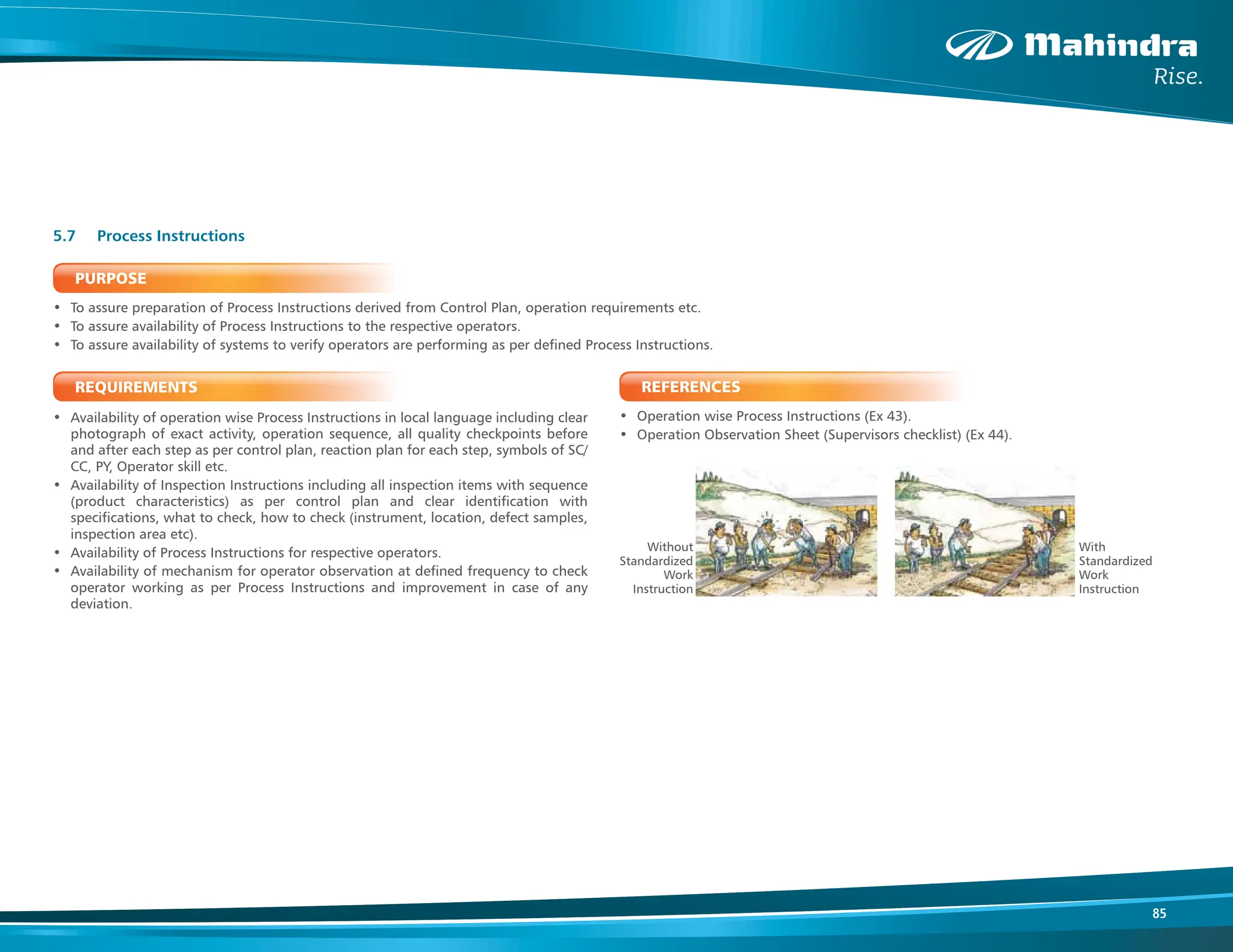

Example 43 - Operationwise Process Instructions

Agalao p`aosaosa (Operation) kao “0” iDfo@T dogao.

p`aosaosa Flaao:

Legends:

@ kaya- p`NaalaI

© caOk PvaaM[-T

® ireo@Sana Plaana

OK

p`aofa[la

kiTMga va

iD/ilaMga

maaoliDMga

iT/imaga va

[nsaT- laa[na kao icapkanaa

i@lap

[nsarT

Inspection

Packing

pOikMga

STANDARD OPERATING SHEET Operation:- Moulding

Department/SBU Signature Document No.

Part Name Name Issue Date

Part No. Authority Prepared By Reviewed By Rev.No.

Date Rev.Date

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

ijammaodarI : AaproTr

@ puranao kpDo sao maSaIna kI safa[- krooM.

@ AavaSyaktaa pDnao pr maaolD kao Tolune tqaa

vaayar ba`uSa kI sahayata sao saaf krooM.(maSaIna caok

ilasT raoja maSaIna caok krnao ko baad AvaSya Baro.)

© maaolD maoM kao[- rbar tqaa Anya pda-qa nahI icapka

haonaa caaihyao.

® icapka haonao pr maaolD Kraba Aayaogaa.

@ maaoilDga ko saaro pOramaITr samaaPt haonao pr maaolD

Kaolakr saavaQaanaIpUvak pIsa sao [nsarT inakalao.

© saBaI pOramaITr samaaPt haonao sao phlao maSaIna

nahI KulanaI caaihe tqaa saavaQaanaIpUva-k [nsarT na

inakalanao Par jvaa[T k,ok hao sakta hO.

® saBaI pOramaITr samaaPt haonao sao phlao maSaIna Kuloana

pr sauprvaa[jar kao saUicat kro tqaa jvaa[T k,ok

haonao pr dubaara maaolD kro.(safod maak- lagaakr

irmaaolD kro.)

@ phlao T,MaijaSana jvaa[MT lagaayaoM , icat/,anausaar maSaIna

mao p,,aofa[-la ka jaoa isara maaolD mao jaanaa hao ]sao

]sa trf lagaayao.icat/ RH ka hO va LH ko ilayao

]lTa lagaayaoM.

© Qyaana do ik jaao p,aofa[-la ijasa kOivaTI mao laganaI hao

]sa ]saI kOivaTI mao lagaayao.varnaa pIsa kI ilap dbaogaI

AaOr pIsa irja@T hao jaayaogaa.

® irja@T pIsa kao sak,Op kr do.

@ sTop nambar 1 va 2 puna : daohrayaoM va B ipbar

jvaa[MT lagaanao ko ilayao icat/anausaar maSaIna mao p,,aofa[-la

ka jaoa isara maaolD mao jaanaa hao ]sao ]sa trf lagaayao.

icat/, RH ka hO va LH ko ilayao ]lTa lagaayaoM. va

]sako baad sTop 4 sao 8 tk daoh

© Qyaana do ik jaao p,aofa[-la ijasa kOivaTI mao laganaI

hao ]sa ]saI kOivaTI mao lagaayao.varnaa pIsa kI ilap

dbaogaI AaOr pIsa irja@T hao jaayaogaa.

® irja@T pIsa kao sak,Op kr do.

@ saOT ikyao gayao vajana ko Anausaar hI kmpa]ND

maaolD kOivaTI mao Dalao,.

© Qyaana do ik kmpa]nD ka vajana kma yaa jyaada

haonao pr pIsa AnDrifla yaa AaovarFlaao hao sakta

hO.

® eosaa haonao pr kmpa]nD ko vajana kI jaa^ca

krayao.

@ maSaIna kao baMd kr do ijasasao maaolD gama- hao

jaayao.

@ maSaIna ko p`aosaosa pOramaITr maSaIna pr lagaI p`aosaosa

SaIT ko Anausaar saOT kroM.

© Actual pOramaITr p`aosaosa SaIT ko Anausaar hI

Aanao caaihyao.

® sahI na haonao pr iSaFT [-ncaa-ja kao batayaoM tqaa

sahI haonao pr hI maSaIna calaayaoM.

@ maaolD mao iDfo@T kI jaa^ca kro.

© maaolD mao AnDrifla ,jvaa[T ko,k ,gaOsa maak- AaOr

Aaovariflaao nahI haonaa caaihe.

® kao[- BaI samasyaa haonao pr dubaara maaolD kro.

(safod maak- lagaakr irmaaolD kro.)

@ p,aofa[-la kao maaolD mao banaI laaoiDMga laa[na tk

laaoD kro.

© Qyaana do ik p,aofa[-la laa[na saoo Aagao yaa pICo laaoD

na hao.Anyaqaa pIsa irja@T hao jaayaogaa.

® irja@T pIsa kao QyaanapUva-k kaT kr dubaara

maaoilDga kro.(safod maak- lagaakr irmaaolD kro.)

@ sTop nambar 1 va 2 puna : daohrayaoM va c ipbar jvaa[MT

lagaanao ko ilayao icat/anausaar maSaIna mao p,,aofa[-la ka jaoa isara

maaolD mao jaanaa hao ]sao ]sa trf lagaayao.icat/, RH ka

hO va LH ko ilayao ]lTa lagaayaoM. va ]sako baad sTop

4 sao 8 tk daoh

© Qyaana do ik jaao p,aofa[-la ijasa kOivaTI mao laganaI hao ]sa

]saI kOivaTI mao lagaayao.varnaa pIsa kI ilap dbaogaI AaOr pIsa

irja@T hao jaayaogaa. qYaana doM ik pIsa mao bala na Aayao.

® irja@T pIsa kao sak,Op kr do.

@ maaolD mao kmpa]nD Dalakr maSaIna ko saa[D mao lagao

dao puSa baTna dbaayao tqaa Qyaana do ik saBaI pOramaITr

caalaU hao jaayao.

© maaolD maSaIna ek baTna sao nahI calanaI caaihe.

® maSaIna ek baTna yaa nahI calaanao kI dSaa mao

sauprvaa[jar kao saUicat kro.

“kaya- krnao sao pUva- jaaMcao :

• raojaanaa A iSaFT mao Daily Machine Check Sheet ko saaro Pvaa[MT caOk kro tqaa ]saka sToTsa SaIT mao Baro.

• galat haonao pr iSaFT [ncaaja- kao saUicat kroM.

pyaa-varNa eMva saurxaa inado-Sa:

• p%yaok haqa maoM dao - dao dstanao phnao

• maaoilDMga maSaIna maoM Aayala laIk nahI haonaa caaihyao.

sambainQat Da@yaUmaoMT:

• Asaamaanya isqait inado-Sa

• Final Inspection Std. baa]MDrI saompla

• irvak- ina-doSa

Significant Characteristic:

• p`aoD@T :

• p`aosaosa:

CC BB

AA BB

CC

AA

hmaara laxya

1

9

8

7 10

2 3 4 5](https://image.slidesharecdn.com/msesmanual1-240229040801-aabc191f/75/MSES-Manual-Mahindra-Mahindra-customer-specific-requirements-90-2048.jpg)