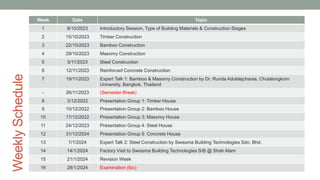

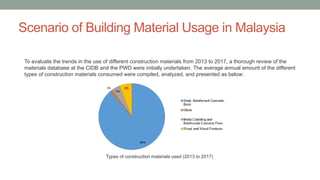

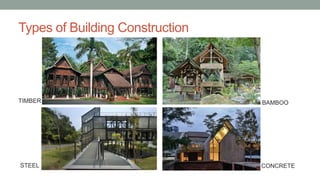

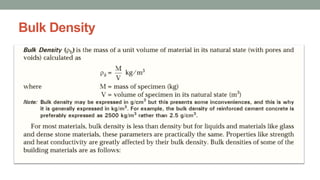

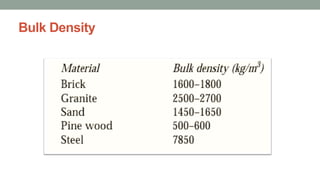

The document outlines the course 'Materials and Construction I' (BIA1021) for the Bachelor of Science in Architecture, including an introduction to basic construction materials and techniques for two-story domestic structures. It details course objectives, assessment methods, weekly topics, and references, and emphasizes understanding construction processes through group assignments and individual projects. The course also provides a schedule of expert talks and factory visits related to various construction materials such as timber, bamboo, steel, and concrete.