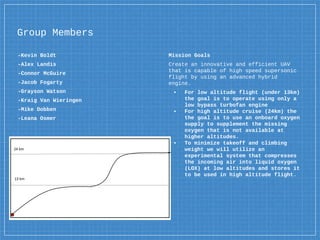

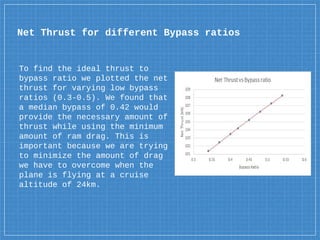

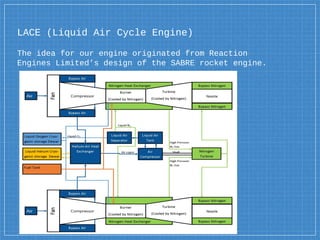

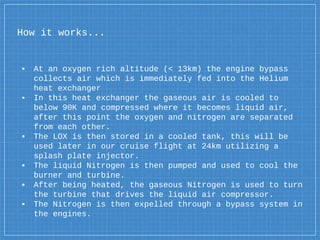

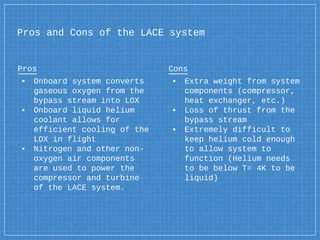

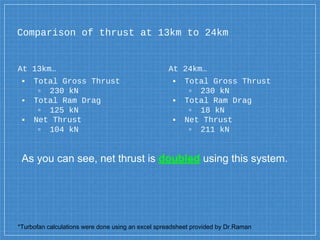

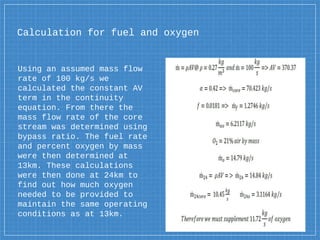

The document describes a proposed hybrid engine for a supersonic UAV capable of high-altitude flight. It would use a turbofan engine below 13km and switch to liquid oxygen stored onboard via a Liquid Air Cycle Engine (LACE) system at higher altitudes. The LACE compresses air into liquid oxygen and nitrogen at low altitude, then injects the oxygen at 24km for comparable thrust. Calculations show net thrust doubles at high altitude due to lower drag. However, liquid oxygen storage adds significant weight, and compressing/storing it in-flight is challenging due to temperature and pressure constraints. The design aims to overcome limitations of air-breathing engines at extreme altitudes but faces technical hurdles