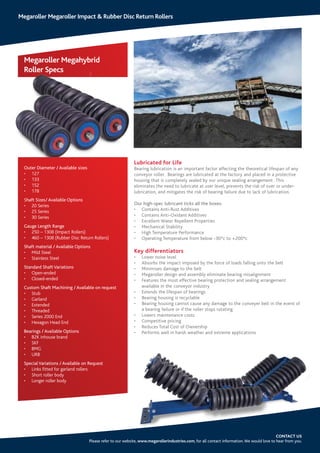

Megaroller is a world leader in conveyor idlers that offers proven, patented technologies for load bearing and high impact rollers. Their key technologies include an advanced sealing arrangement and a high-impact bearing and seal housing that effectively seals rollers and absorbs impacts. Megaroller's impact and rubber disc return rollers utilize these technologies to deliver strength and durability for handling large loads of falling materials in conveyor systems.