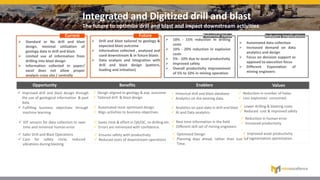

The document discusses the benefits of integrating and digitizing drill and blast operations. Currently, drill and blast design utilizes minimal geology data and information from drilling is limited in blast design. Data is also collected in paper and excel formats that do not allow for proper analysis. With digitization and integration, drill and blast design can be tailored to geology and expected blast outcomes. Data can be collected, analyzed, and used for future blasts. This can result in 10-15% reduction in drilling costs, 10-20% reduction in explosive costs, and 5-10% improvement in asset productivity and overall mining operation productivity. It also improves safety. The industry will see automated data collection, increased demand for data analytics and decision support, and