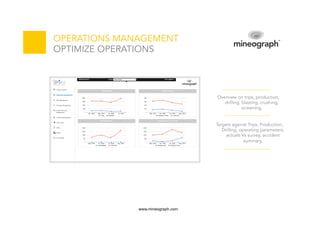

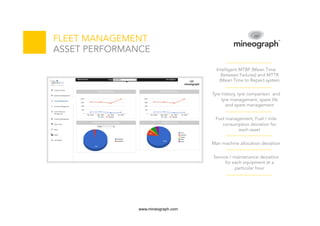

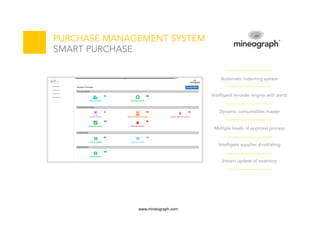

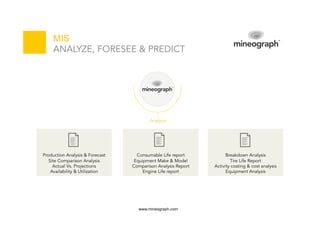

Mineograph is a comprehensive online mining software that aims to empower and optimize mining operations through increased productivity, cost reduction, and improved planning. The software provides modules for inventory management, human resource management, purchase management, project management, operations management, and fleet management. It utilizes telematics data from GPS, IoT, and OBD devices to provide real-time tracking of assets, production, and operations. The dashboard and business intelligence features allow users to analyze performance, costs, and deviations to better manage the business.