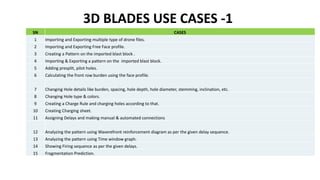

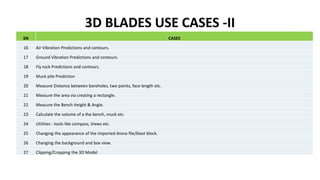

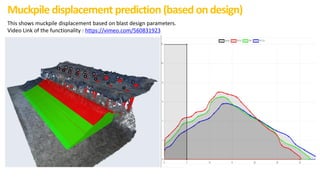

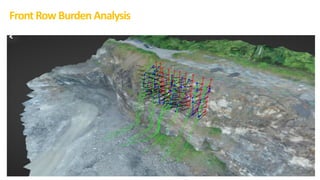

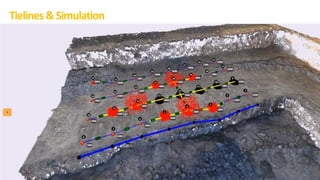

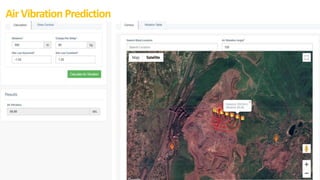

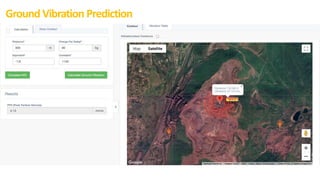

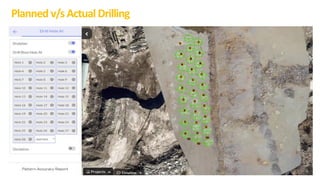

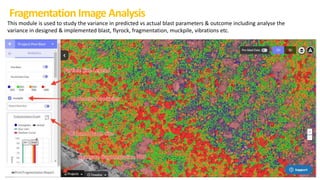

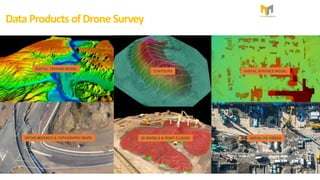

The document discusses various applications of drone data and MineExcellence's drone platform for mining operations. Some key applications mentioned include blast design and optimization, drilling and MWD data collection and analysis, blast information management, fragmentation analysis, and utilities like volumetric analysis. The platform allows import of various file formats from drone surveys and integration of drilling and blast data to optimize blast design and assess variances. Case studies demonstrate benefits like faster data processing, improved recovery and accuracy, and potential cost savings from reducing overdrilling.