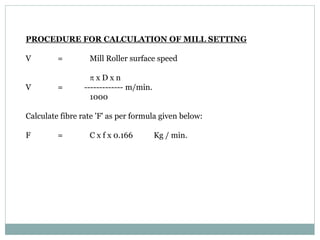

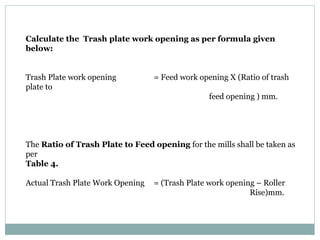

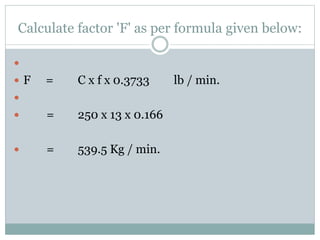

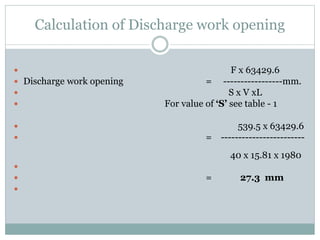

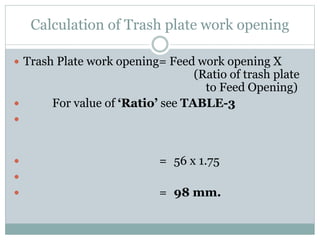

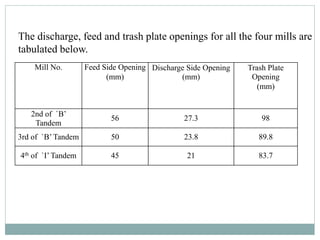

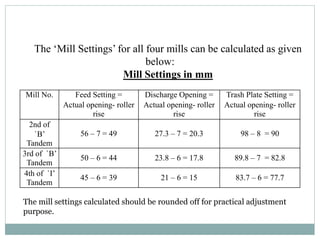

This document provides instructions for calculating mill settings for a sugar cane mill. It defines key terms like mean effective diameter and work openings. It lists required data like crush rate, fiber percentage, roller dimensions, and speed. Formulas are provided to calculate the fiber rate and determine the discharge, feed, and trash plate work opening sizes based on this data and adjustment ratios from provided tables. An example calculation is shown for a specific mill. The resulting recommended mill settings for the discharge, feed, and trash plate openings are presented in a table.