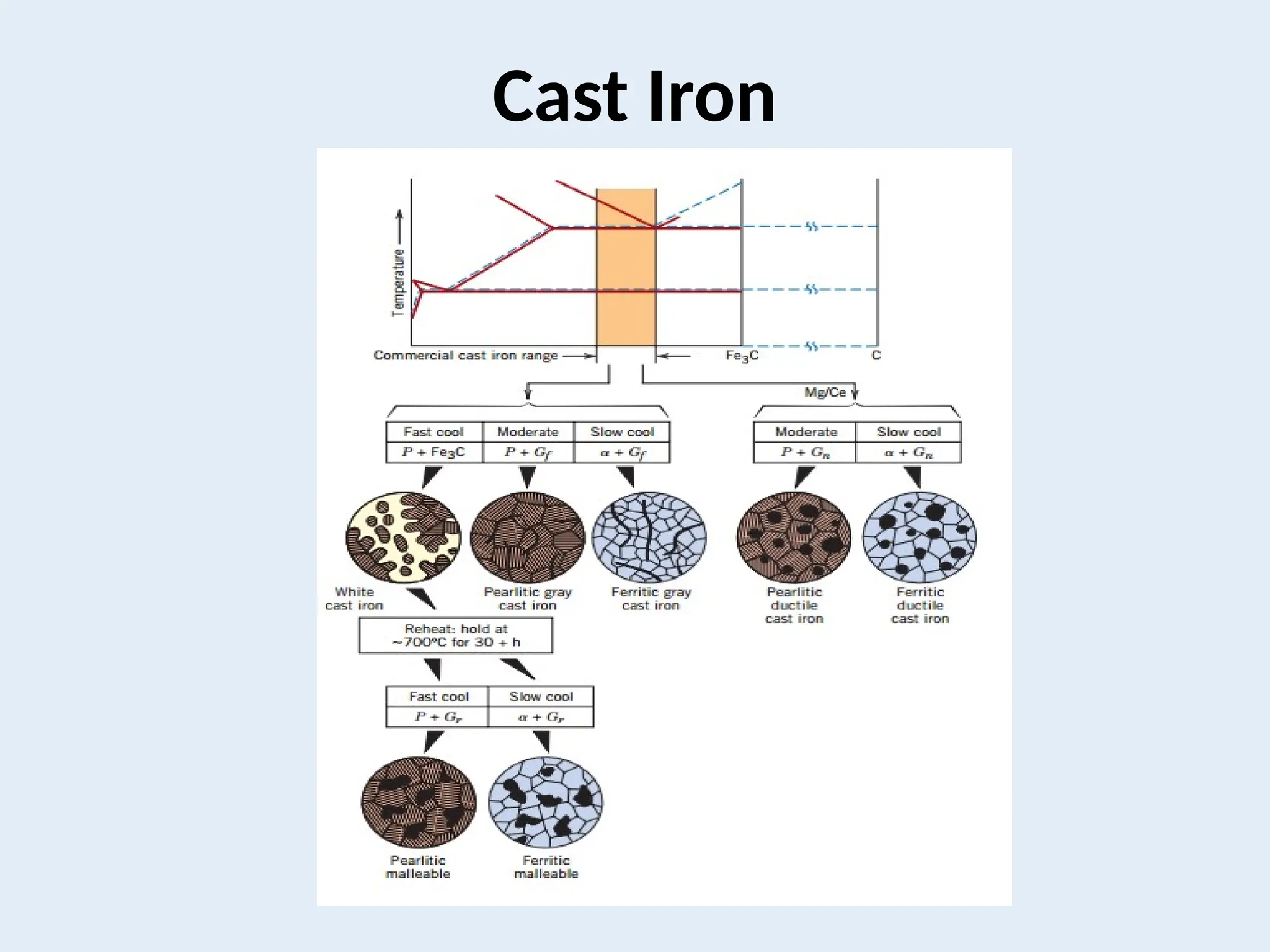

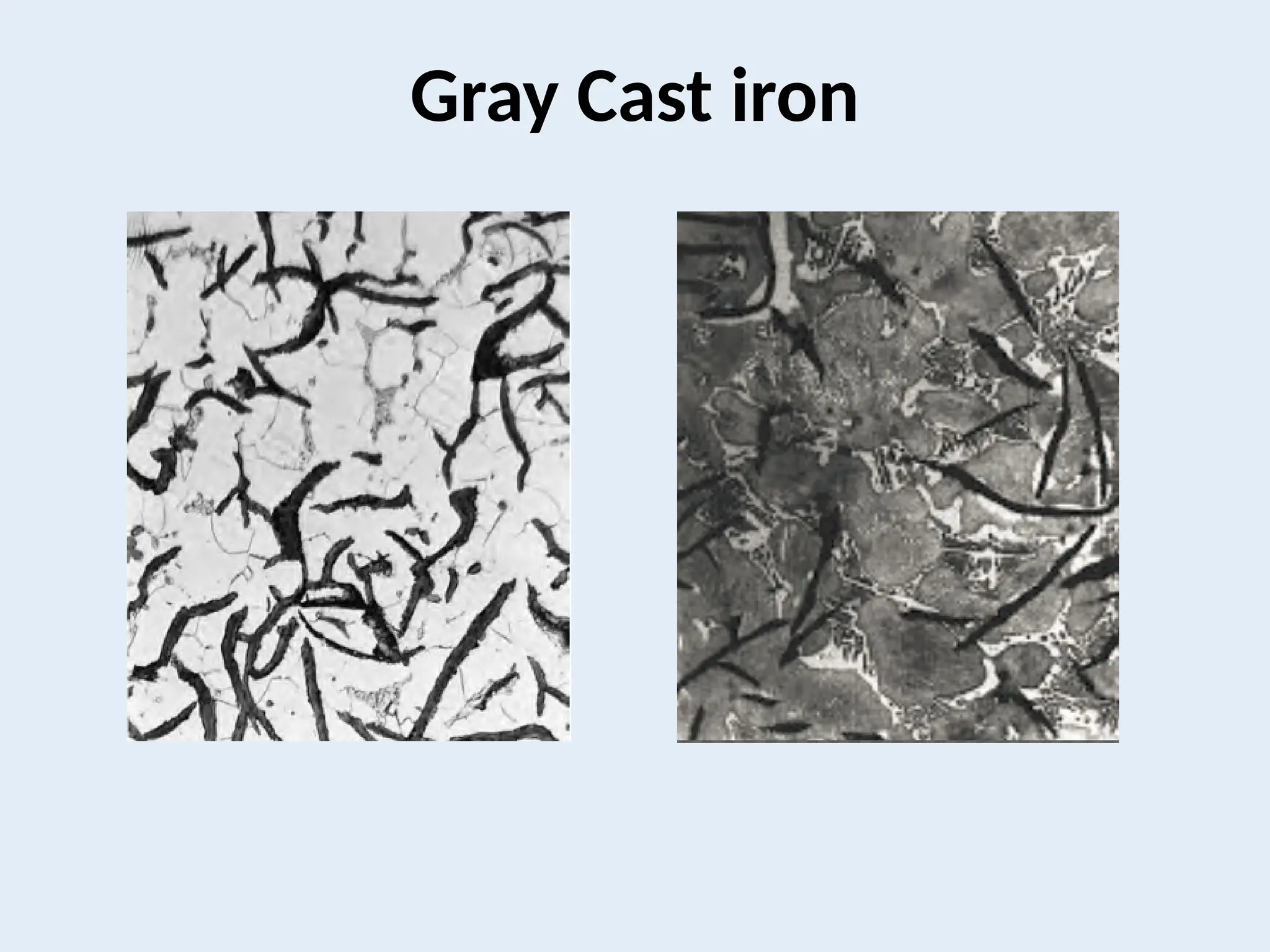

The document discusses cast iron, emphasizing its composition (2-4.5% carbon, 0.5-3% silicon) and properties, including strength, ductility, and castability. It outlines the impact of cooling rates and composition on microstructure, distinguishing between gray and white cast iron, with gray iron known for its graphite flakes and high wear resistance, while white iron is characterized by its hardness and brittleness. Applications for these materials range from heavy machinery to wear-resistant surfaces, highlighting their industrial utility.