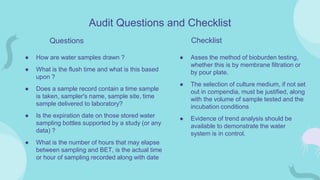

The microbiology laboratory audit presentation outlines procedures for the microbiological evaluation of water, raw materials, and environmental monitoring. It includes guidelines for sampling, testing of water quality, and prevention of bacterial diseases, emphasizing adherence to WHO norms and the importance of method validation. Additionally, it presents a checklist for auditing processes and monitoring techniques used in microbiological testing.