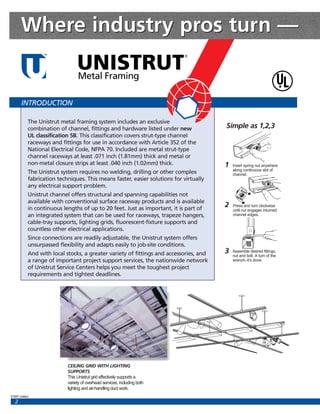

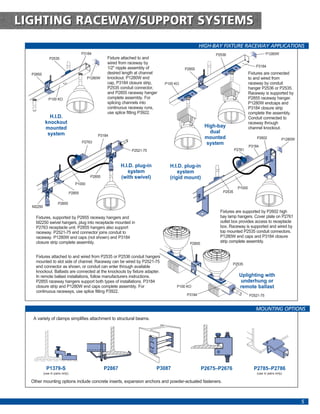

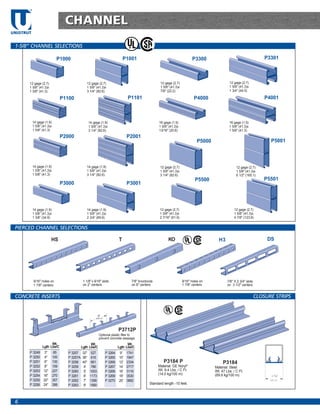

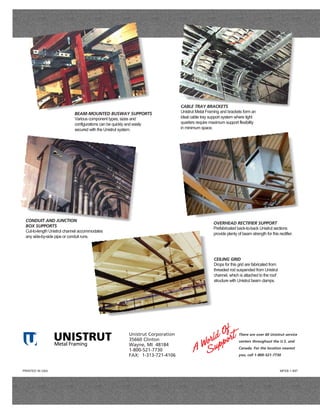

The document provides an overview and guide for using Unistrut metal framing systems for electrical construction applications. It describes that Unistrut channel and fittings are listed under UL classification 5B for use as strut-type channel raceways per NEC Article 352. The system requires no welding or complex fabrication, offering flexibility and easy adjustments. Unistrut provides integrated solutions for raceways, hangers, supports and more applications to help meet project requirements.