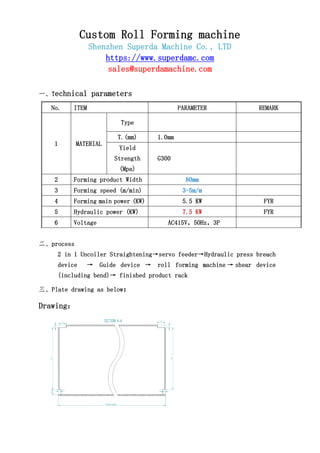

This document summarizes the specifications of a custom roll forming machine. The machine can form materials from 1.0mm to 1.6mm thick into profiles up to 80mm wide at speeds of 3-5m/min. The main components include an uncoiler and straightener, servo feeder, hydraulic punching system, guide device, 10-station roll forming machine, hydraulic shear, and a flat collection rack. The electrical control system uses a PLC and touch screen interface to automatically control the process and monitor equipment status.