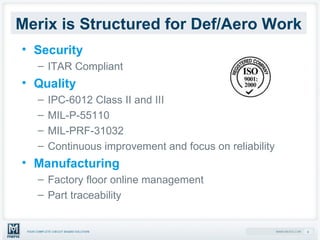

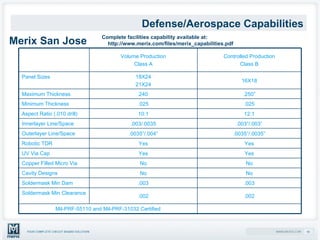

Merix Corporation provides circuit board solutions for the defense and aerospace industries. They have multiple facilities certified to quality and reliability standards required for these markets. Merix focuses on advanced technology, engineering support, and quality management to deliver reliable boards for critical programs such as the B787 Dreamliner, Falcon III radio, and Rockwell Collins systems. Their goal is to grow defense and aerospace sales to over 25% of their business.