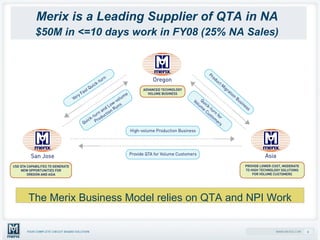

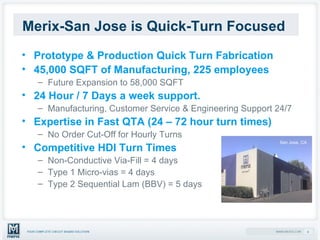

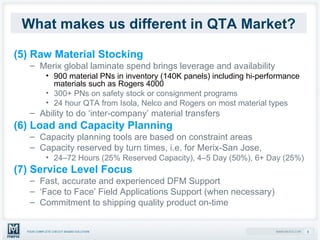

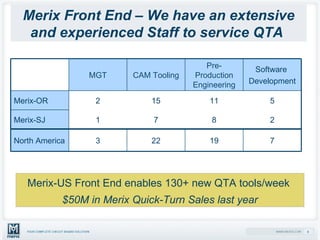

Merix is a leading provider of quick-turn circuit board manufacturing in North America, with over $50 million in sales from quick-turn orders in the previous fiscal year. They have two quick-turn focused manufacturing facilities in San Jose, CA and Forest Grove, OR that offer 24/7 support and turnaround times as fast as 24 hours. Merix differentiates itself from competitors by offering a full suite of quick-turn and engineering services to support customers throughout the entire product development process.