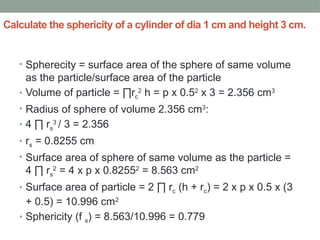

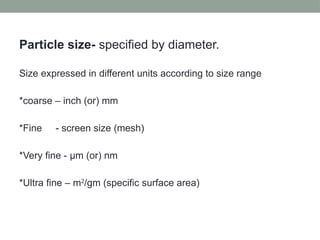

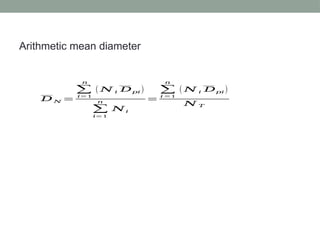

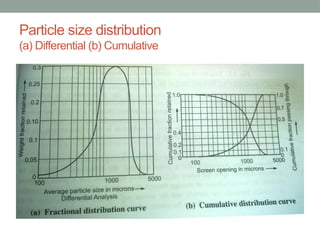

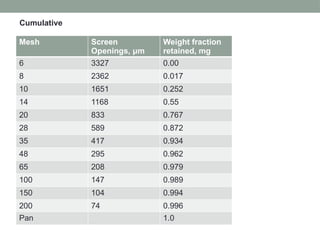

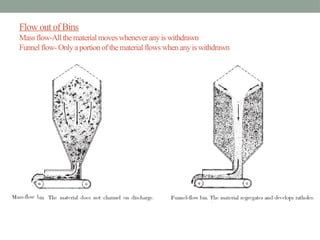

The document outlines mechanical operations in chemical engineering, focusing on particle size analysis, including concepts of shape, size, distribution, and methods such as screening and sedimentation. It discusses the calculation of particle sphericity, mean diameters, and the importance of screening in ensuring the correct sizing of materials for processing. Additionally, it addresses storage methods for solids, with examples involving pressure estimation in silos filled with different materials.

![Spherecity of cube

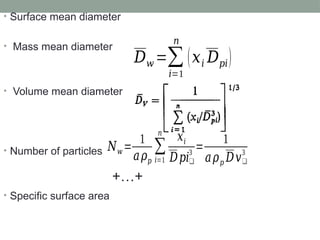

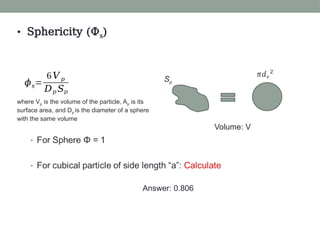

• Ψ = As / Ap Where: As is the surface area of the equivalent

sphere and Ap is the measured surface area.

The sphericity can have a value ranging from 0-1, where Ψ = 1

for an ideal sphere.

• The volume of a spherical particle is:

• Vp= (1/6) π dp

3

Where: dp is the diameter of the particle.

• The surface area of a sphere is:

• As = π dp

2

= π [ (6 Vp / π)(1/3)

]2

Thus, for a particle, Ψ can be

calculated by measuring its volume and surface area:

• Ψ = As / Ap = π (6 Vp / π)(2/3)

/ Ap An example: A cube measuring

1 × 1 × 1 cm has a volume of 1 cm3

, and a surface area of 6 ×

(1 × 1) = 6 cm2

. Its sphericity is:

• Ψ = π × (6 × 1 / π)(2/3)

/ 6 = 0.806](https://image.slidesharecdn.com/momodule1-240812110231-353ce302/85/Mechanical-Operations-slides-for-chemical-engineers-6-320.jpg)