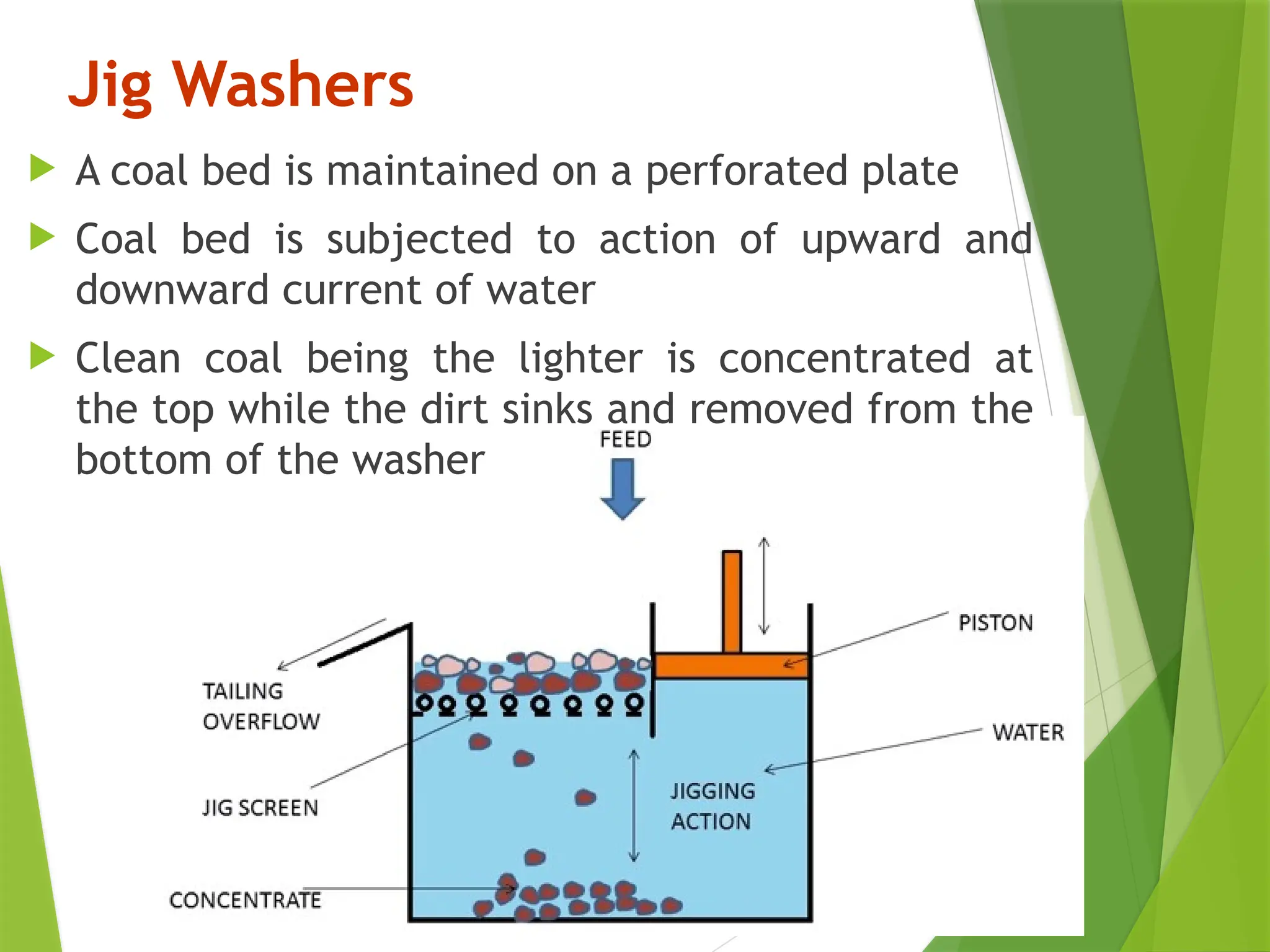

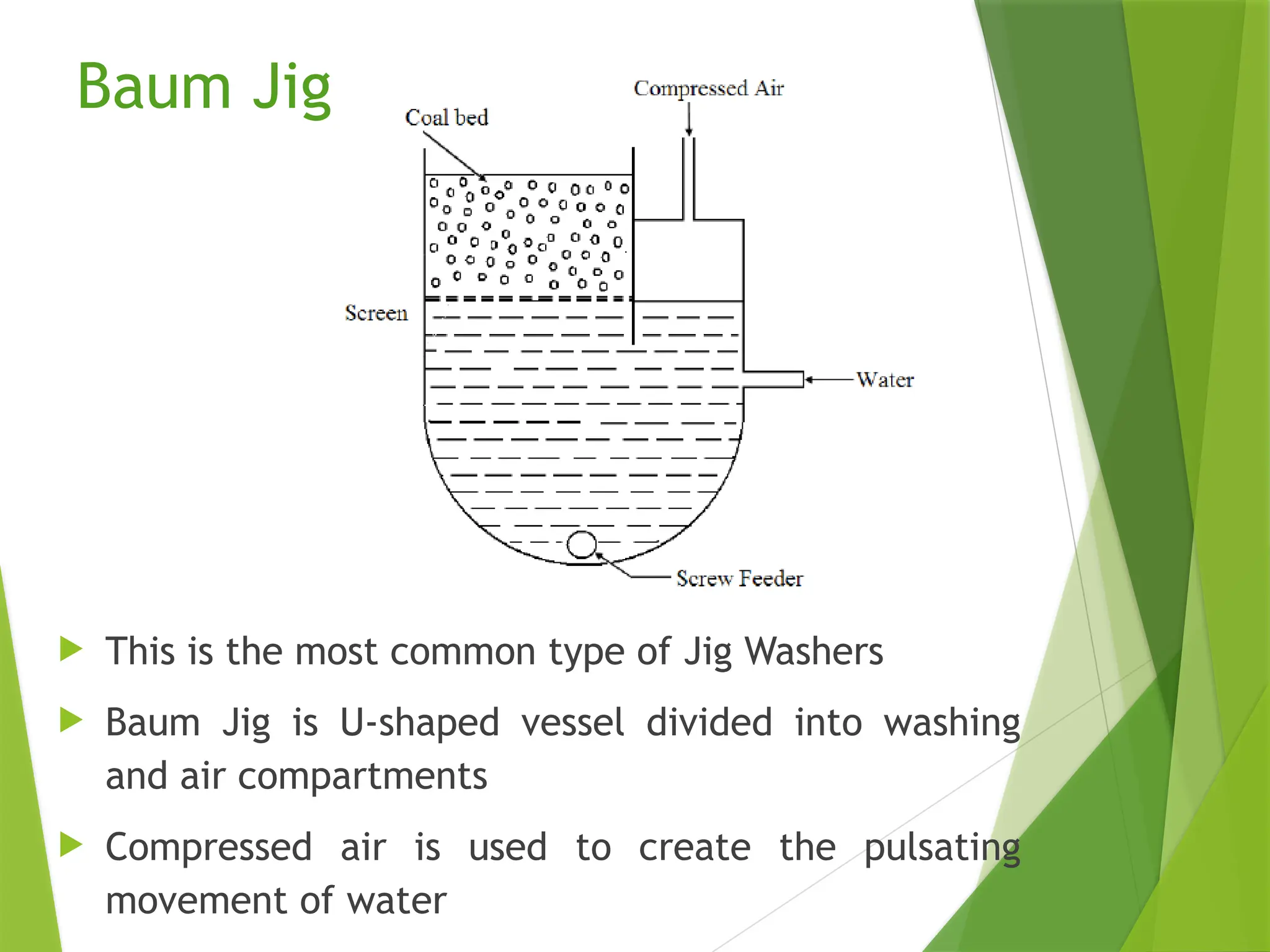

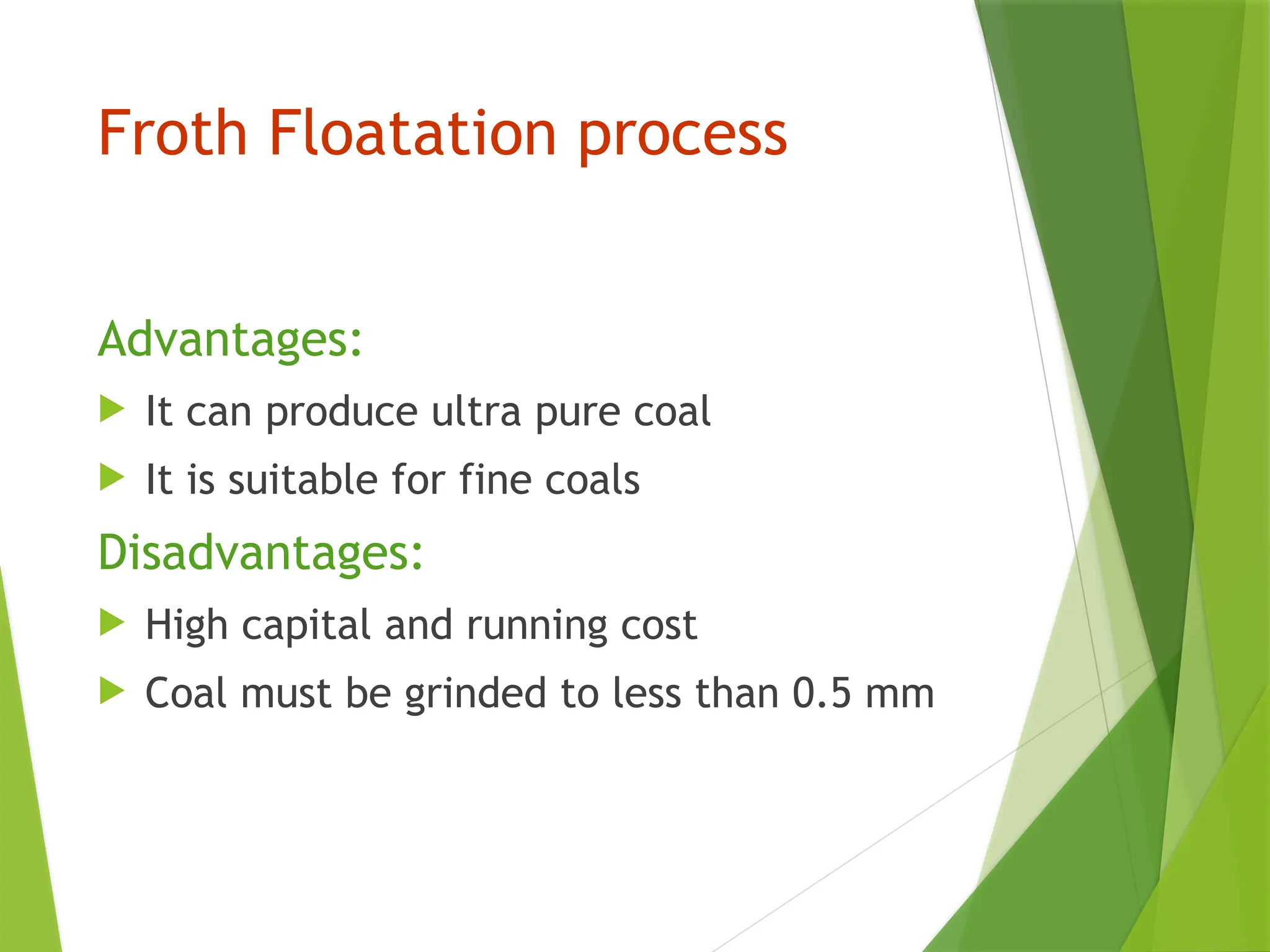

The document discusses various coal washing methods including jig washers, cyclone washers, and froth flotation processes. Each method has its own advantages in terms of separation efficiency and operational flexibility, but also presents challenges such as higher power consumption and costs. Additionally, it outlines coal storage requirements to ensure sufficient supply during peak firing rates.