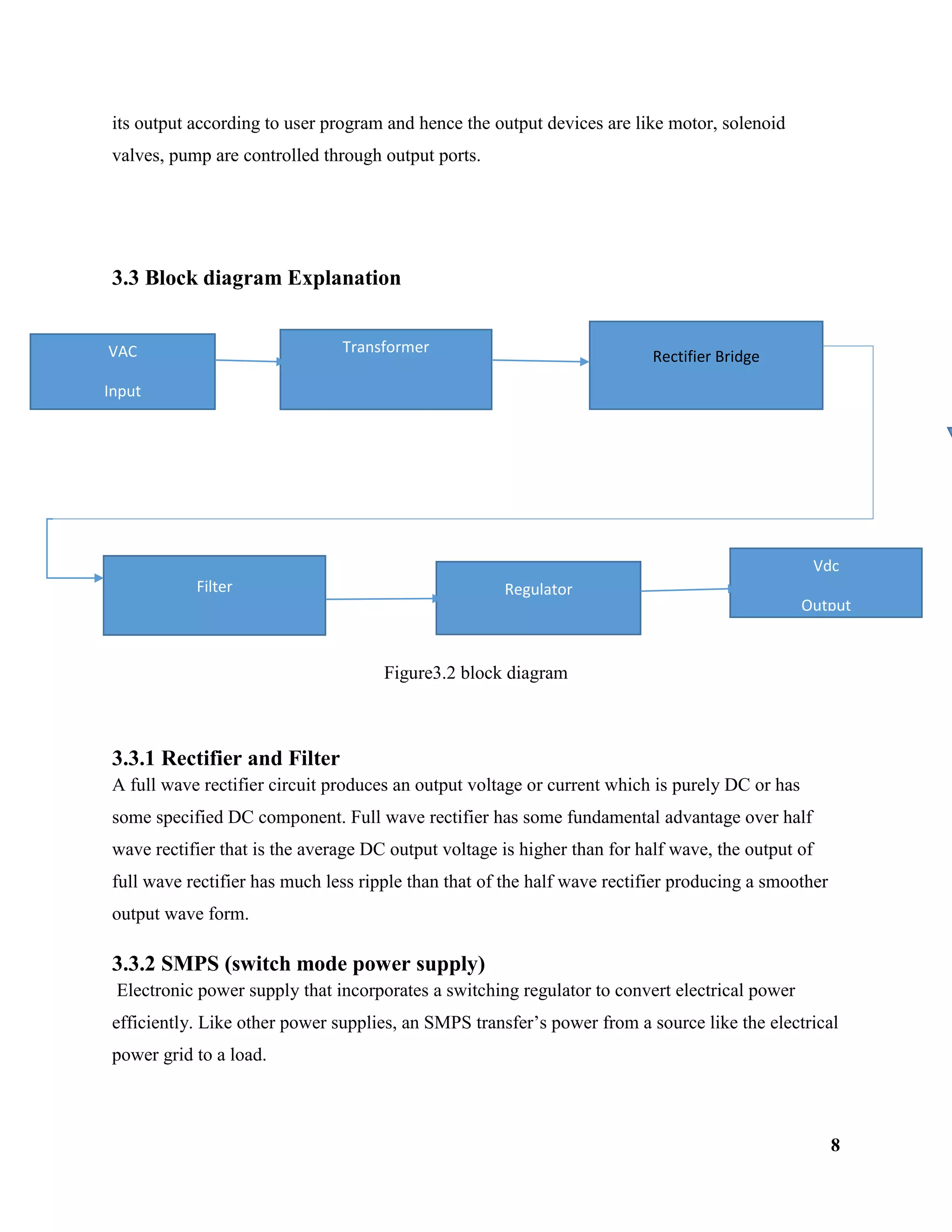

This document describes an automatic water level controller project using a programmable logic controller (PLC). The project was completed by three students for their Electrical and Computer Engineering department. It uses two capacitive sensors and actuators including a pump and valve to control the water level in a tank. When the water reaches the high level sensor, the valve opens to decrease the level to the low sensor. When the low level is reached, the valve closes and pump operates to increase the level again. The PLC is programmed to control the water inflow and outflow to maintain the level automatically.

![5

CHAPTER TWO

LITERATURE REVIEW

Tank Water Level Indicator and Controller Using Arduino by Amrit Kumar Panigrahi, Chandan

Kumar Singh, Diwesh Kumar, Nemisha Hota [13]. This paper gave the idea of using echo

method. It also helped us in making the system’s mechanism simpler. When the sound waves are

transmitted in the environment, they are reflected back as ECHO. Waves generated by the

ultrasonic sensors is sent to the water tank and their time of travelling and coming back is noted

and after few calculations we can estimate the level of water in the tank. The motor pump is

automatically turned ON when the water level becomes low and turned OFF when the tank is

full. But this project is some limitations on its complexity during installation, costly, and when

the medium which wave signal transmitted is varied the ultrasonic sensor is not measure

properly.

Yuriy H. [1] designed a PLC based system to control liquid level by using Radar sensor

remotely. This system measures the liquid level, volume, temperature, and pressure and controls

these measurements remotely. The system consists of the Radar sensor, temperature sensors,

discrete level sensors and a programmable logic controller. The PLC is programmed by the FBD

programming language. To transfer data between all the components, the communication method

that the authors choose is RS 485 bus with an ASCII based protocol. The authors state that

communication protocol actually reduces or eliminates interference during the process of data

transmission. In order to monitor the system, the authors also design a human machine interface

(HMI). Finally, the experimental result corroborates the exactitude and reliability of their system.

Pooja A. [2] carried a test on a PLC based single water tank control system using PID controller.

In their system, an HMI which is programmed on NI-Lab VIEW is connected to an Allen

Bradley Micro830 PLC through the Modbus RTU communication protocol. According to Pooja

A., this system is designed for training purpose in order to have a complete understanding of

PLC based process control system design. In their literature, some necessary modeling is

introduced, such as the water tank modeling, transducer modeling, and the control valve

modeling. Some parameters, such as the resistance of the control valve, and current to pressure

(I/P) converter, are estimated depending on the experimental data by using the method of least

squares. Furthermore, Pooja et al. applied PID algorithm into the PLC to achieve a better result.](https://image.slidesharecdn.com/45888487651299822393-220402081418/75/power-pfd-11-2048.jpg)

![28

REFERENCE

[1] Yuri H. “PLC based system to control liquid level by using Radar sensor remotely”, 2015.

[2] Pooja A. “PLC based single water tank control system using PID controller”, 2015.

[3] V.R Jadhav “Programmable logic controller”, 2016.

[4] Pty Ltd. Rota-Loo “Environmental Equipment Composting Toilet Brochure”, 2006.

[5] L.A. Bryan and E. A. Bryan “Programmable controller Theory and implementation.”

[6] Joon Heo.A. “Security Mechanism for Automation Control in PLC-based Networks.”

[7] Jon S. Wilson “Google Books Sensor Technology Handbook.”

[8] M Gauger “automation applications that integrate wireless sensor networks.”

[9] M .varchola. Zigbee “Automation wireless sensor network.” 2007.

[10] Prof. Hesham Khairy “Automation Technology”.

[11]Crispin A.J. “Programmable logic controller and their engineering application”, first

Edition, books Britain, 1996.

[12] Stevenson J. “Fundamentals of programmable logic controller”, first edition, prentice hall,

1998.

[13] Amrit Kumar Panigrahi, Chandan Kumar Singh, Diwesh Kumar, Nemisha Hota “Tank

Water Level Indicator and Controller Using Arduino.” And al et.](https://image.slidesharecdn.com/45888487651299822393-220402081418/75/power-pfd-34-2048.jpg)