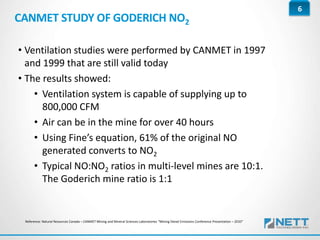

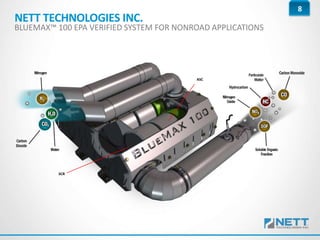

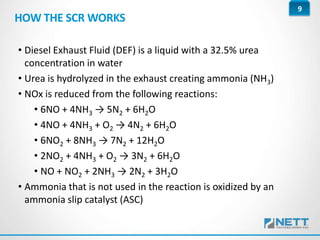

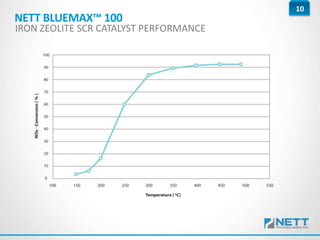

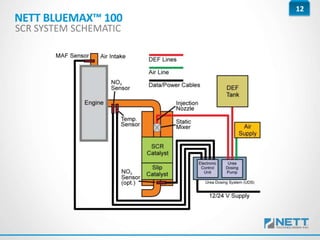

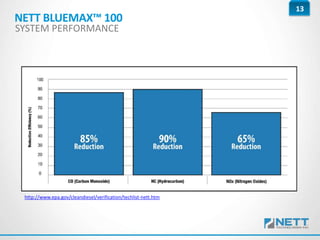

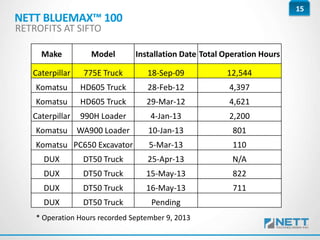

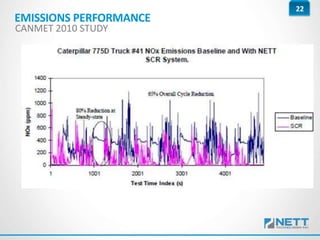

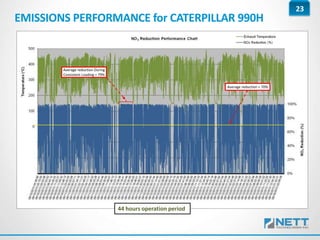

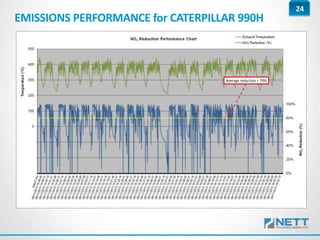

Nett Technologies Inc. presented a summary of the selective catalytic reduction (SCR) emissions retrofit solutions implemented at Sifto Canada's salt mine, focusing on the significant NOx reductions achievable with urea-based SCR systems. The 2010 demonstration project revealed a 65% reduction in NOx emissions for the Nett Bluemax 100 system, making it the preferred choice for future retrofits in the mining fleet. SCR systems are highlighted as effective pollution control technologies adaptable to various mining equipment, ensuring regulatory compliance and operational efficiency.