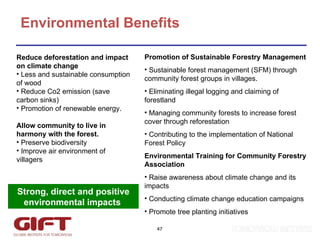

- The document provides background information on Cambodia, including its population, economic growth, poverty levels, and environmental challenges like deforestation.

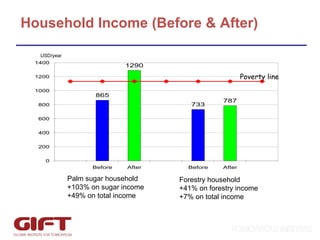

- It introduces Eco-Biz, a social enterprise created in 2007 to develop market opportunities for sustainable forestry products in Cambodia. Eco-Biz aims to improve livelihoods while protecting the environment.

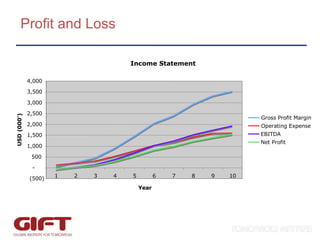

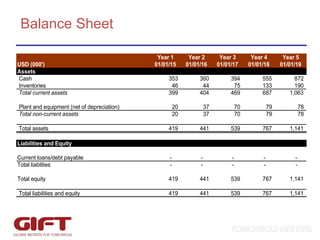

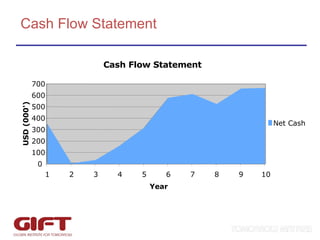

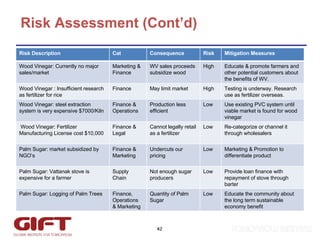

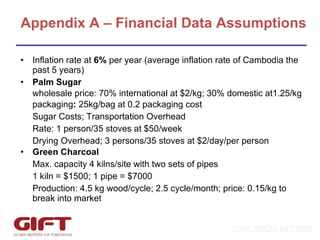

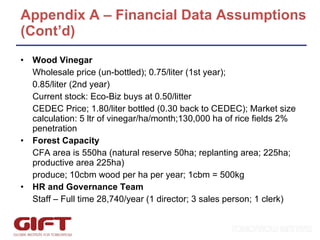

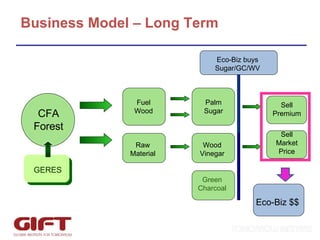

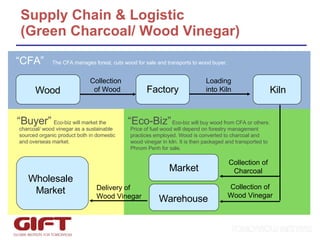

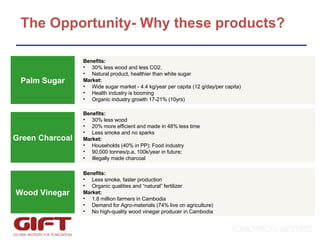

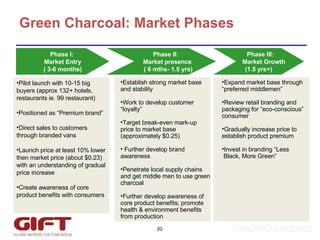

- Eco-Biz produces and sells palm sugar, green charcoal, and wood vinegar. The document outlines Eco-Biz's business model, production methods, supply chain, quality assurance, and marketing plan to sell these products domestically and internationally.

![Forging Multi-stakeholder Partnership Creating a viable business model for village community products Village Community CFA - develop supply of sustainable wood as fuel/raw material for production Domestic palm producers - the seller of the unpackaged product at source GERES assist and educate CFA to develop sustainable wood supplies build Vattanak stoves for the domestic palm producer Consumers CEDAC - Education and penetration of small scale agriculture markets for wood vinegar Others (e.g. Restaurant) build [and maintain] the Yoshimura kiln for Eco-Biz educate CFA in Phase to operate Yoshimura kiln as a co-operative Eco-Biz GERES Consumers Village Community](https://image.slidesharecdn.com/masterdeckmay081230am-124216507629-phpapp01/85/Business-Case-for-EcoBiz-27-320.jpg)