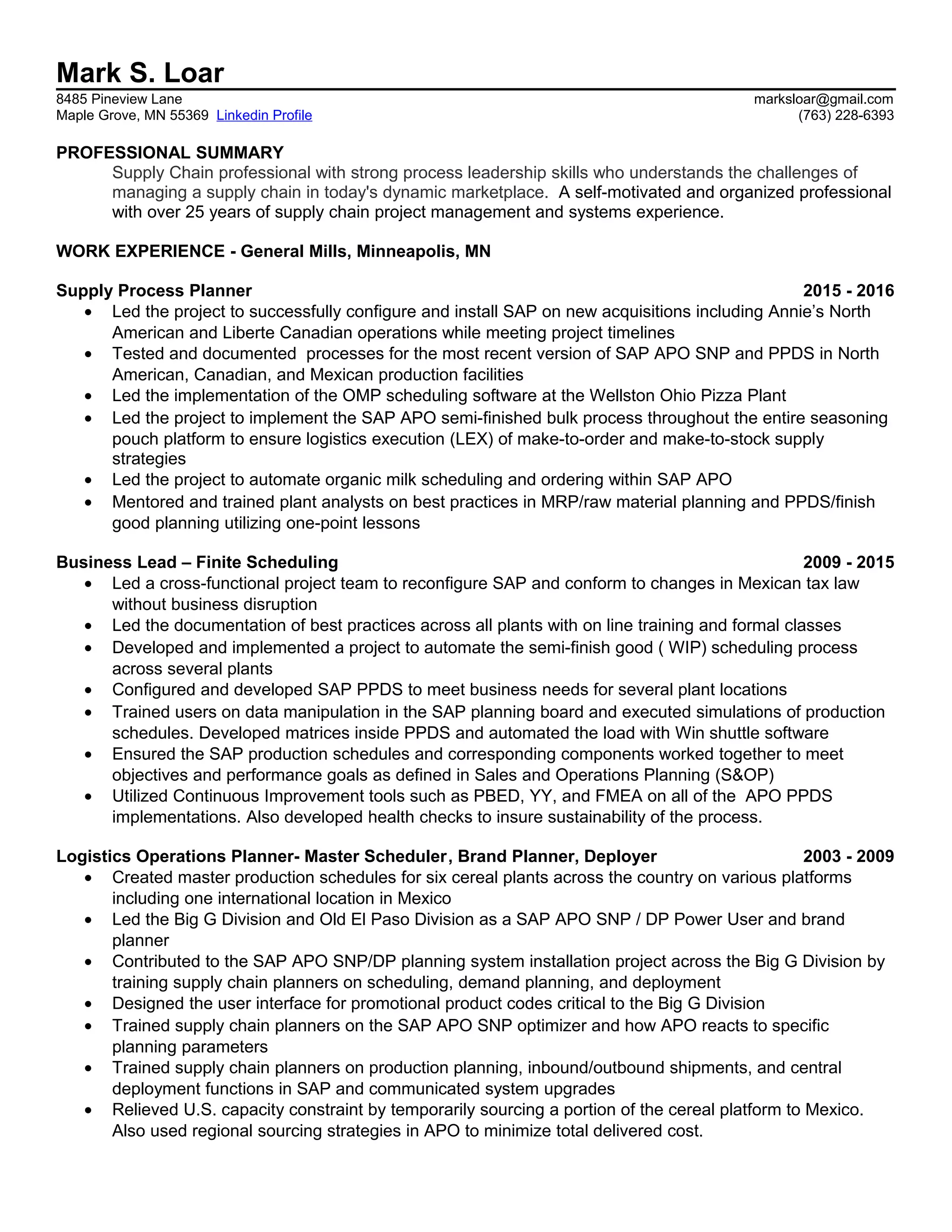

Mark S. Loar has over 25 years of supply chain experience, including project management, systems implementation, and process leadership roles at General Mills. He has extensive experience implementing and configuring SAP modules like APO, SNP, PPDS, and WMS. Most recently, he led projects to configure SAP for new acquisitions and automate scheduling and ordering processes. Loar mentors colleagues and develops training programs to share best practices.