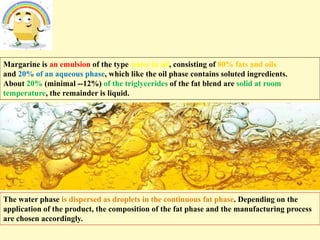

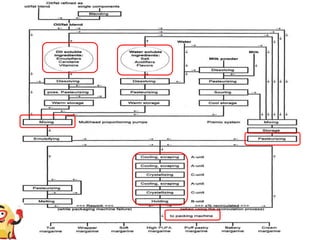

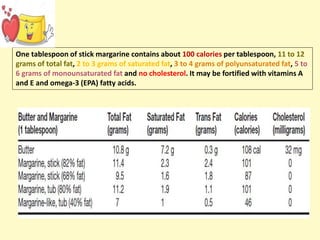

Margarine is an emulsion consisting of 80% fats and oils and 20% of an aqueous phase. It is produced through several steps including preparation of the water and fat phases, emulsion preparation, pasteurization, chilling, crystallization, kneading, and packing. Margarine provides around 100 calories and contains saturated, polyunsaturated, and monounsaturated fats while being fortified with vitamins and minerals. It is a designed food staple that can be tailored to provide nutritional and functional benefits.