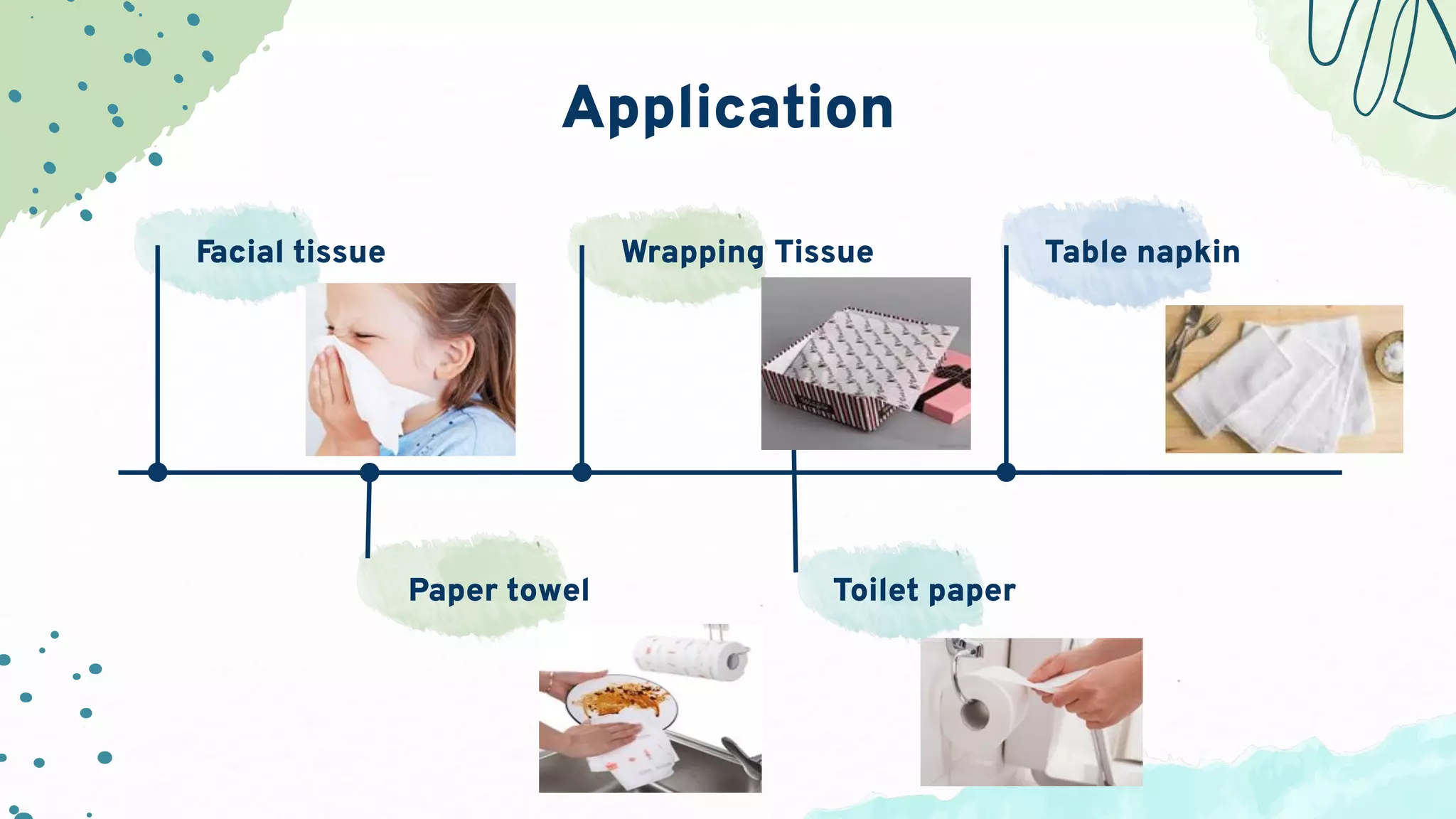

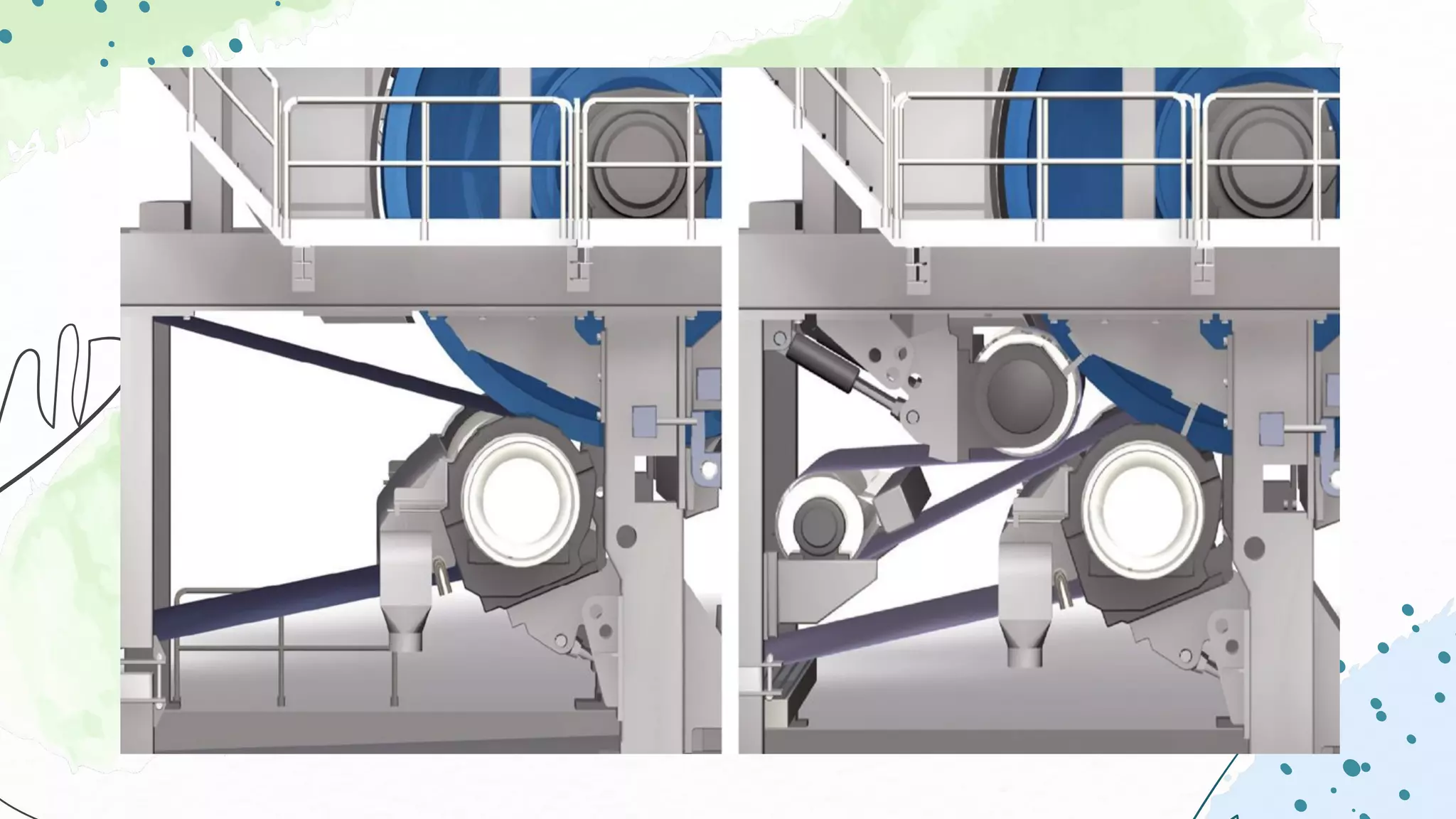

The document provides a detailed overview of tissue paper, including its applications, manufacturing process, materials, and properties. It outlines the various types of tissue products such as facial tissue, paper towels, and toilet paper, highlighting their uses and characteristics. Additionally, it identifies Kooka Paper Manufacturing Sdn Bhd as the Malaysian company responsible for producing these products.