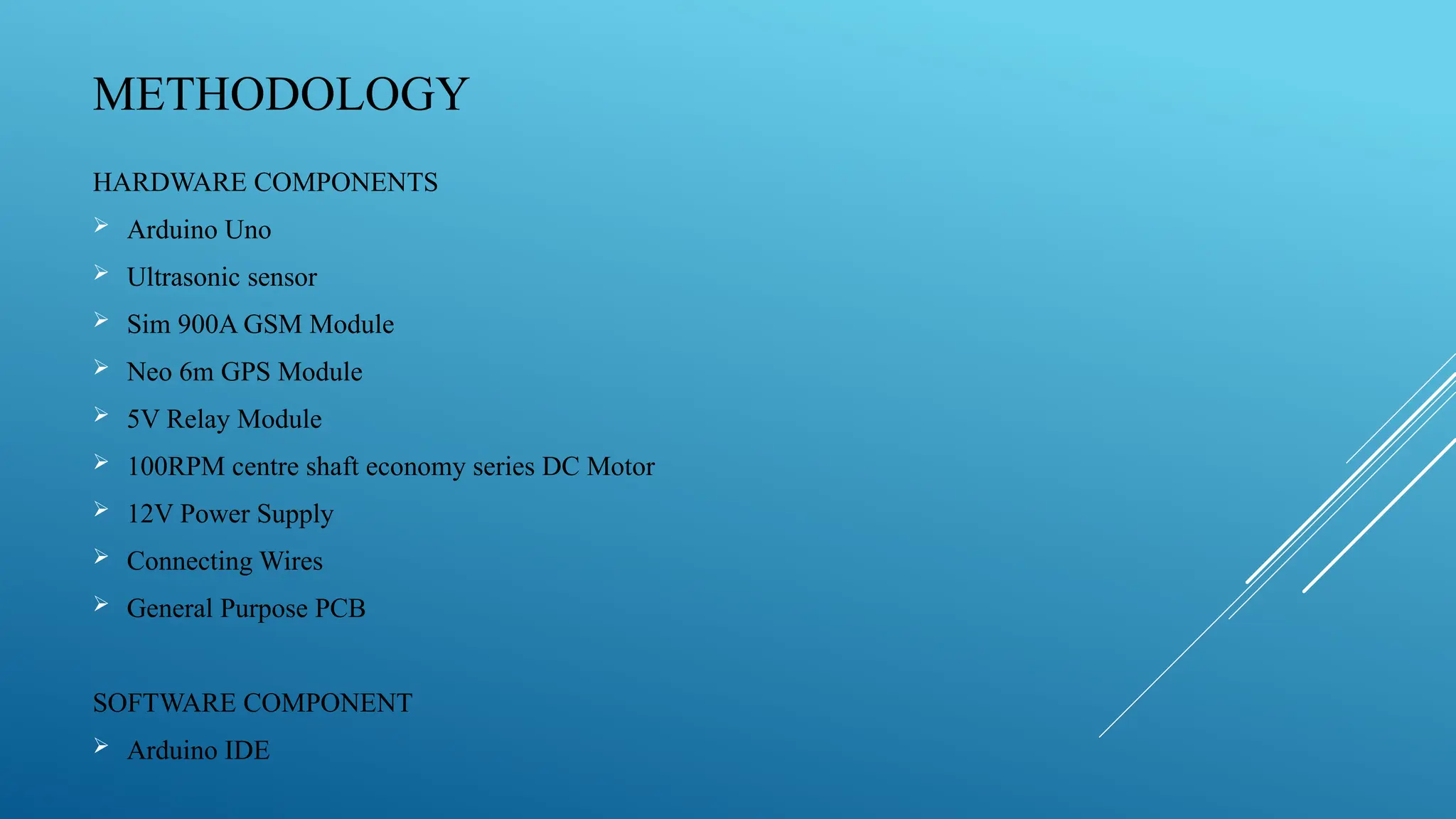

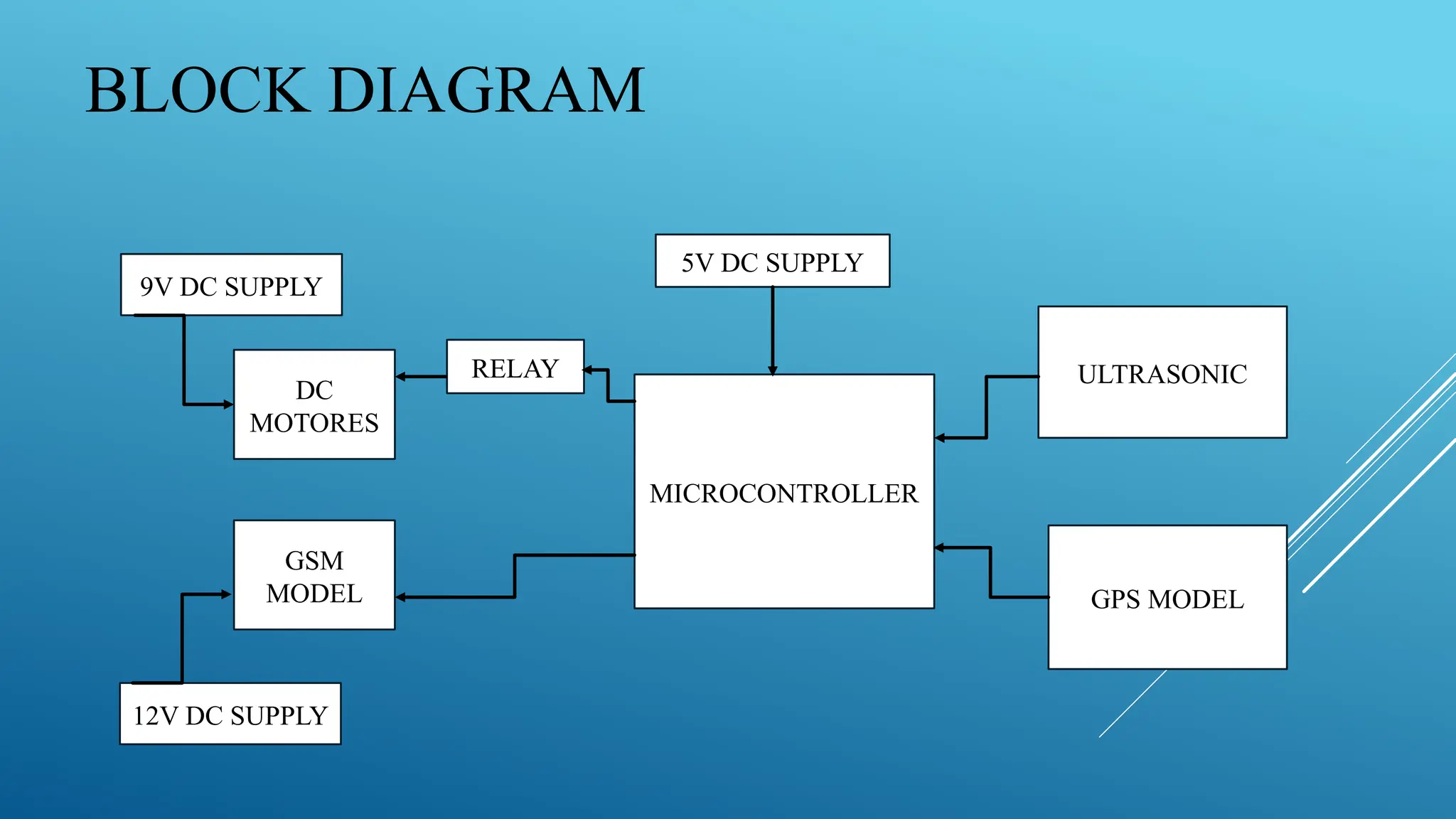

The document outlines a project for developing a robust railway crack detection system using ultrasonic sensors integrated with an Arduino controller to enhance railway safety by detecting cracks in tracks automatically. It highlights the significant problem of railway accidents caused by undetected cracks and proposes real-time monitoring and location reporting functionalities. The project aims to improve safety, reduce maintenance costs, and enhance the overall efficiency of the railway network.