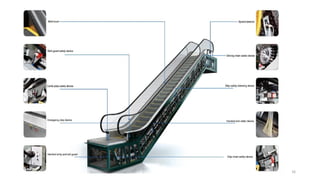

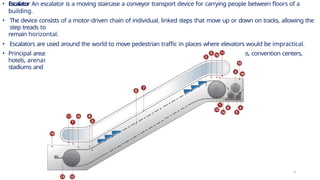

Escalator An escalator is a moving staircase a conveyor transport device for carrying people between floors of a building.

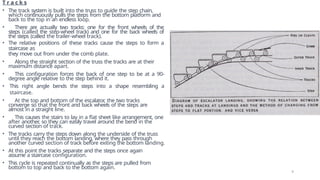

The device consists of a motor-driven chain of individual, linked steps that move up or down on tracks, allowing the step treads to

remain horizontal.

Escalators are used around the world to move pedestrian traffic in places where elevators would be impractical.

Principal areas of usage include department stores, shopping malls, airports, transit systems, convention centers, hotels, arenas,

stadiums and public buildings.

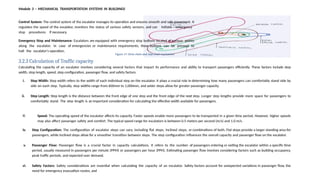

![• The Advantages and Disadvantages of Escalators, like moving walkways, are often powered by constant-speed

alternating current

motors and move at approximately 0.3 - 0.6 m per second.

• The typical angle of inclination of an escalator to the horizontal floor level is 30 degrees with a standard

rise[clarification needed] up to about 18 m.

• Modern escalators have single-piece aluminum or stainless steel steps that move on a system of tracks in a

continuous loop.Advantages Disadvantages

Have the capacity to transport

large number of people at

shorter time.

Only convenient for short vertical

distance, better to use lifts for

lengthier vertical distance

Faster mode of transportation for

short vertical distances

Takes up space to install

Can be placed/substituted as normal

staircase even during malfunction.

Higher risk of injuries

No waiting internal except during

heavy traffic

May be weather – proved for outdoor

use

Moves at a constant speed at

approximately 0.3-0.6m per second

with a standard rise up to about 18m

4](https://image.slidesharecdn.com/m3escalators-250801044748-1baf30fa/85/M3-ESCALATORS-BUILDING-SERVICES-III-ARCHITECTURE-4-320.jpg)