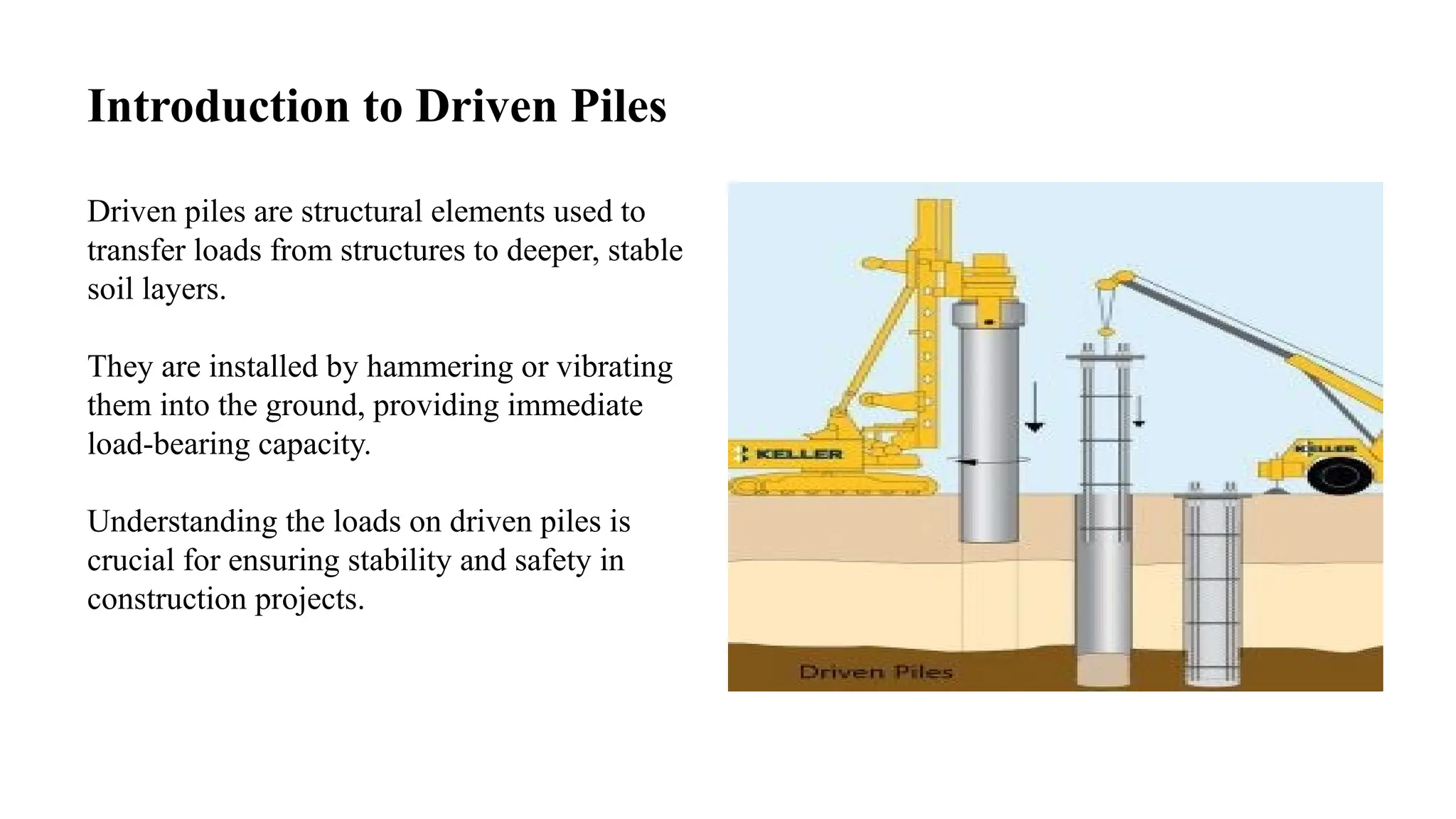

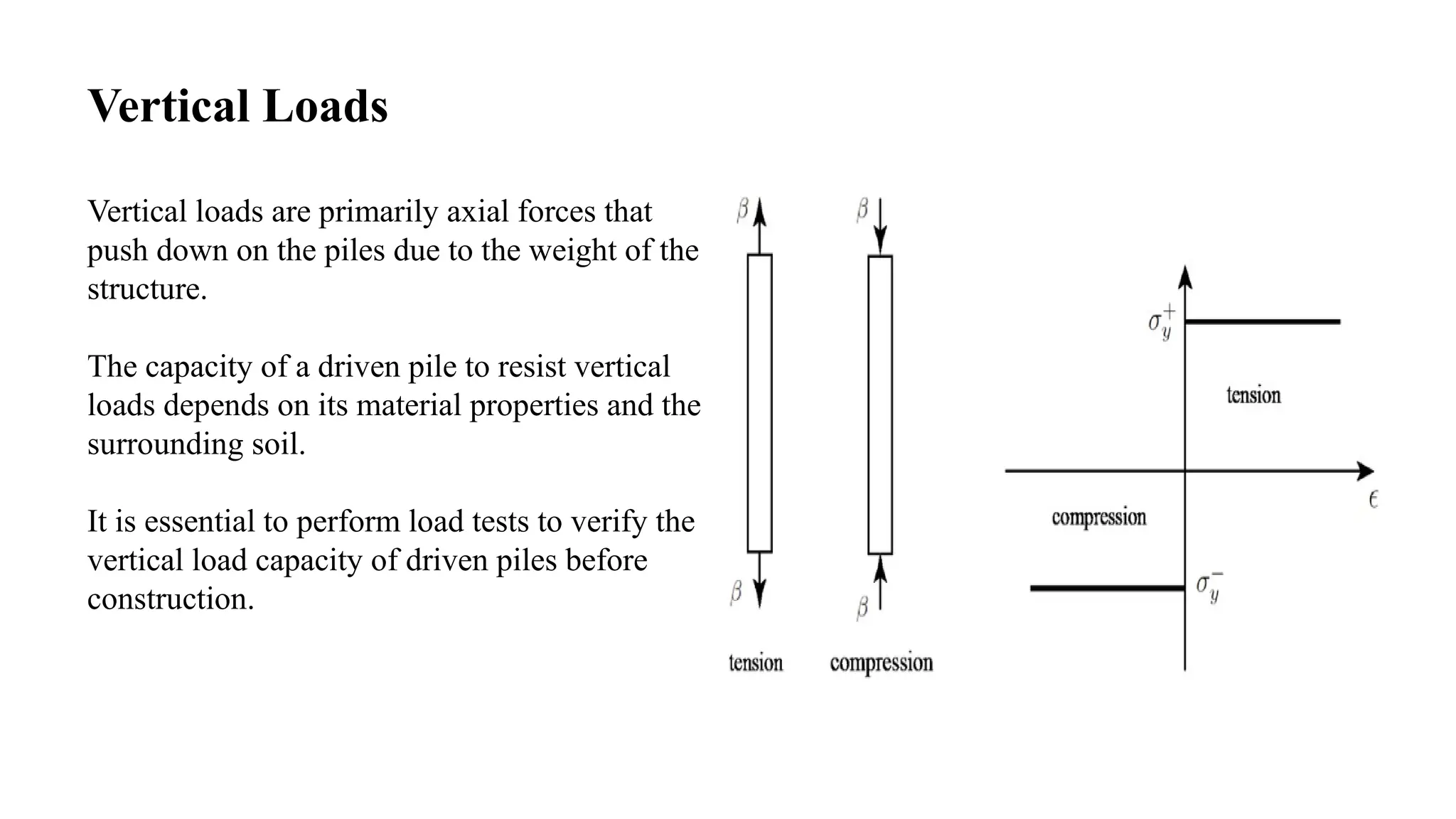

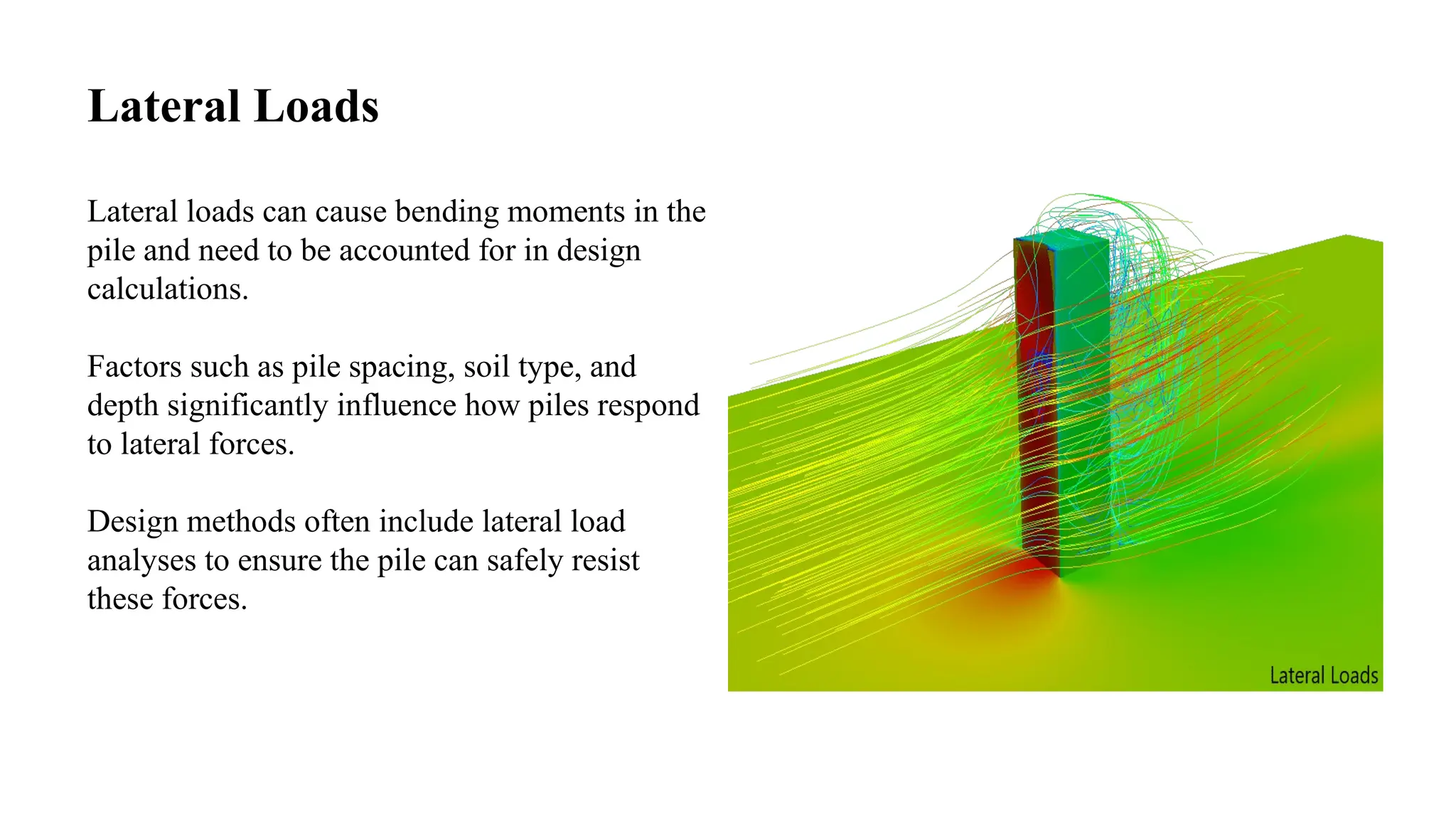

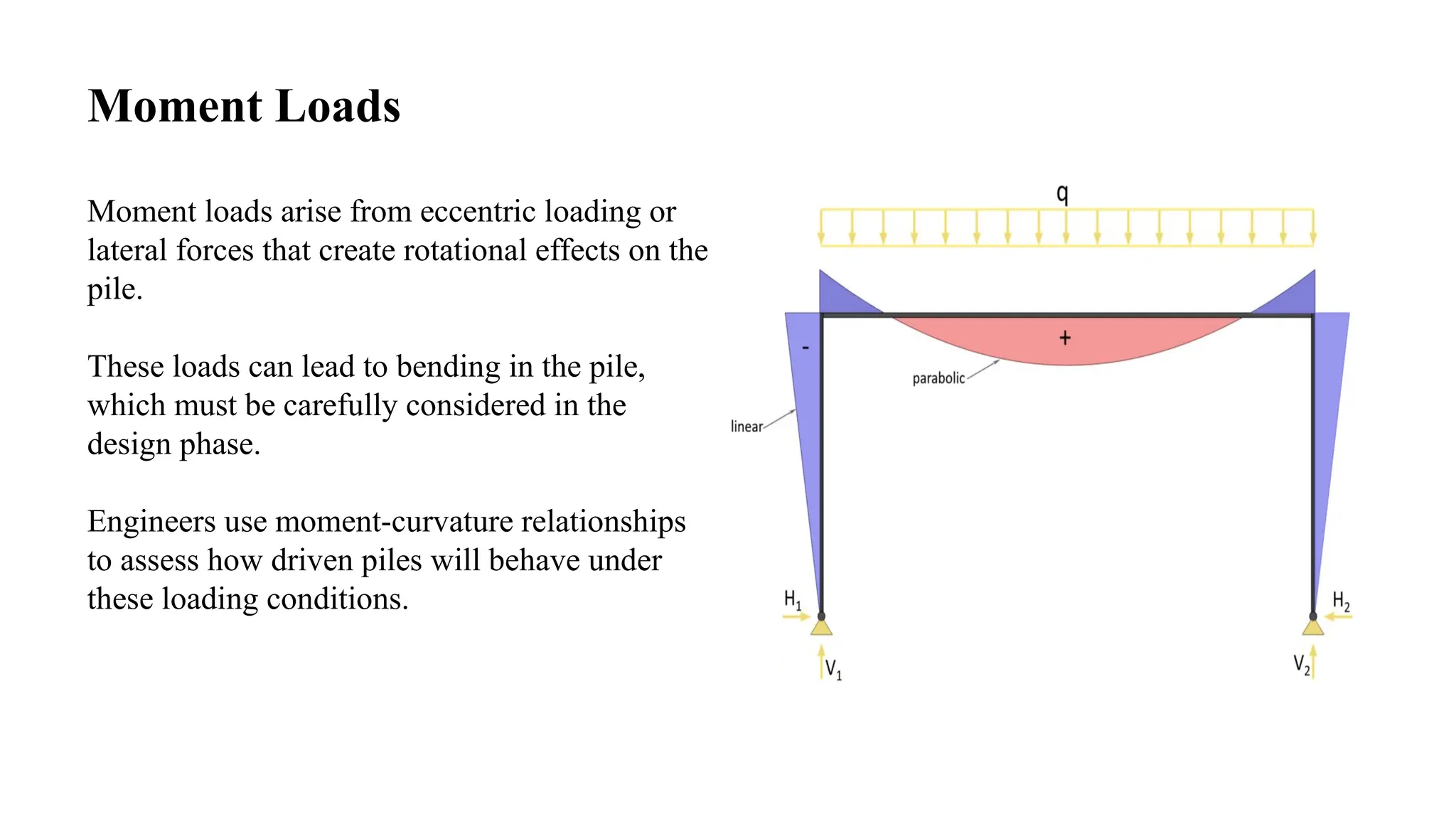

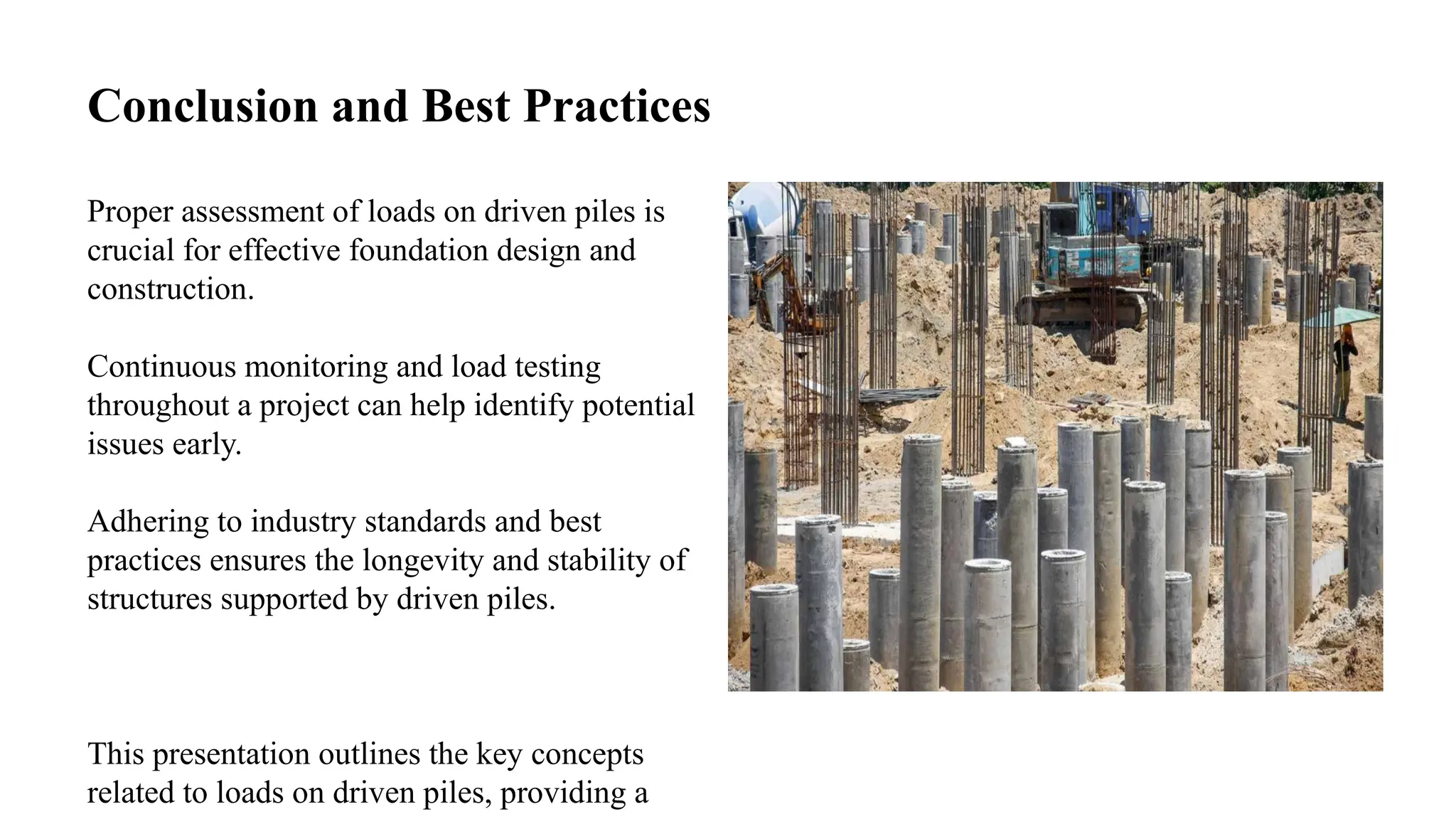

Driven piles are structural elements designed to transfer loads to stable soil layers, with crucial load types including vertical, lateral, and moment loads. Key factors affecting their load capacity include soil type, material properties, installation method, and penetration depth, necessitating thorough load testing methods for safety. Continuous monitoring and adherence to best practices during construction are essential for ensuring the stability and longevity of structures using driven piles.