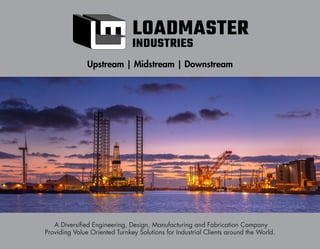

Loadmaster Industries was founded in 1986 and has over 30 years of experience providing engineering, manufacturing, and construction services to the upstream, midstream, and downstream oil and gas industries. It offers turnkey solutions such as designing, fabricating, testing, and installing large steel structures, piping systems, and equipment. Loadmaster has capabilities in structural steel, mechanical equipment, piping, vessels, and provides field services from its facilities in Louisiana and Texas.