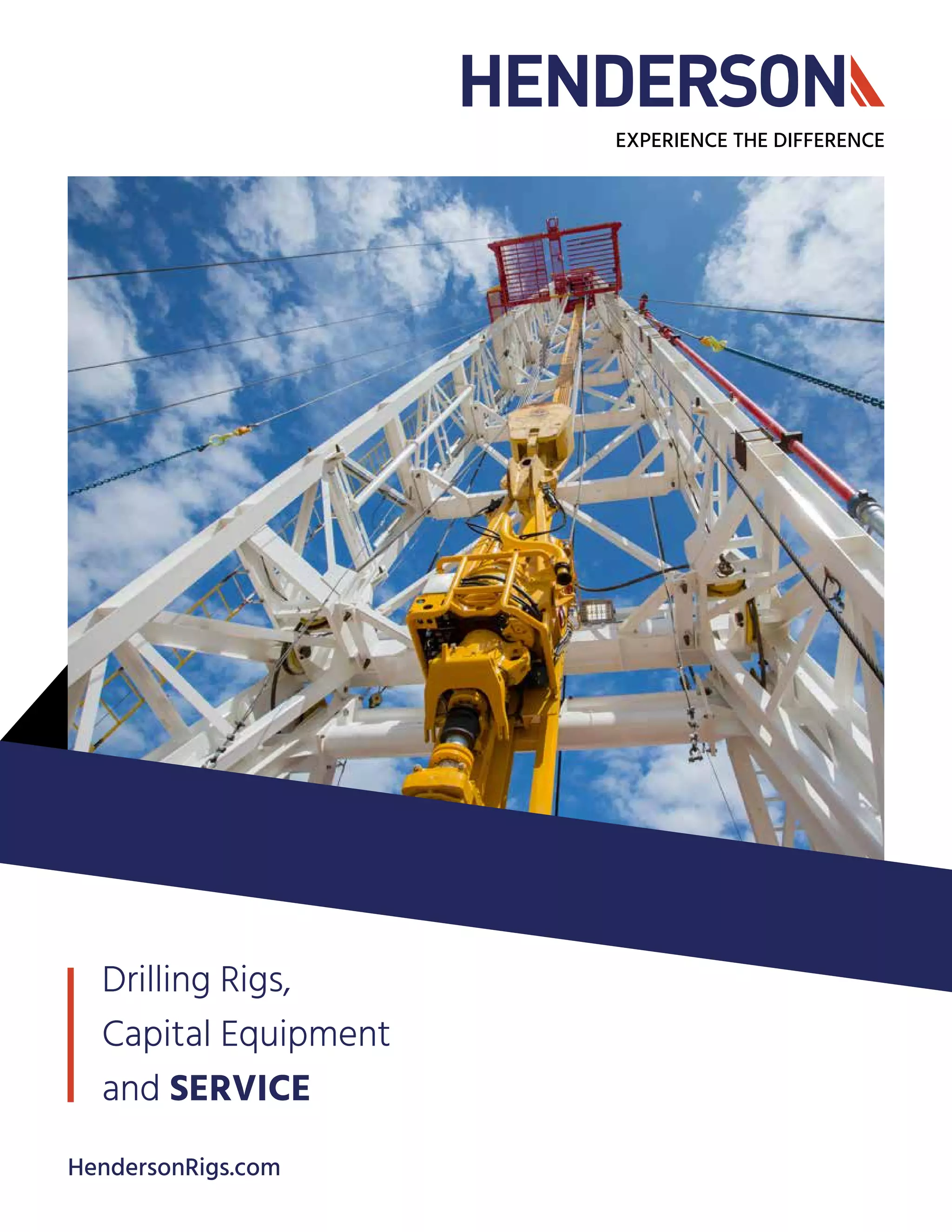

Henderson is a Houston-based manufacturer of drilling equipment for the oil and gas industry, focusing on quality, safety, and environmental responsibility. The company offers a range of products and services, including the design and sale of drilling rigs, high-pressure piping, and comprehensive field service support, all while prioritizing employee well-being. With a commitment to quality and transparency, Henderson aims to build long-lasting relationships with its clients through reliable products and services.