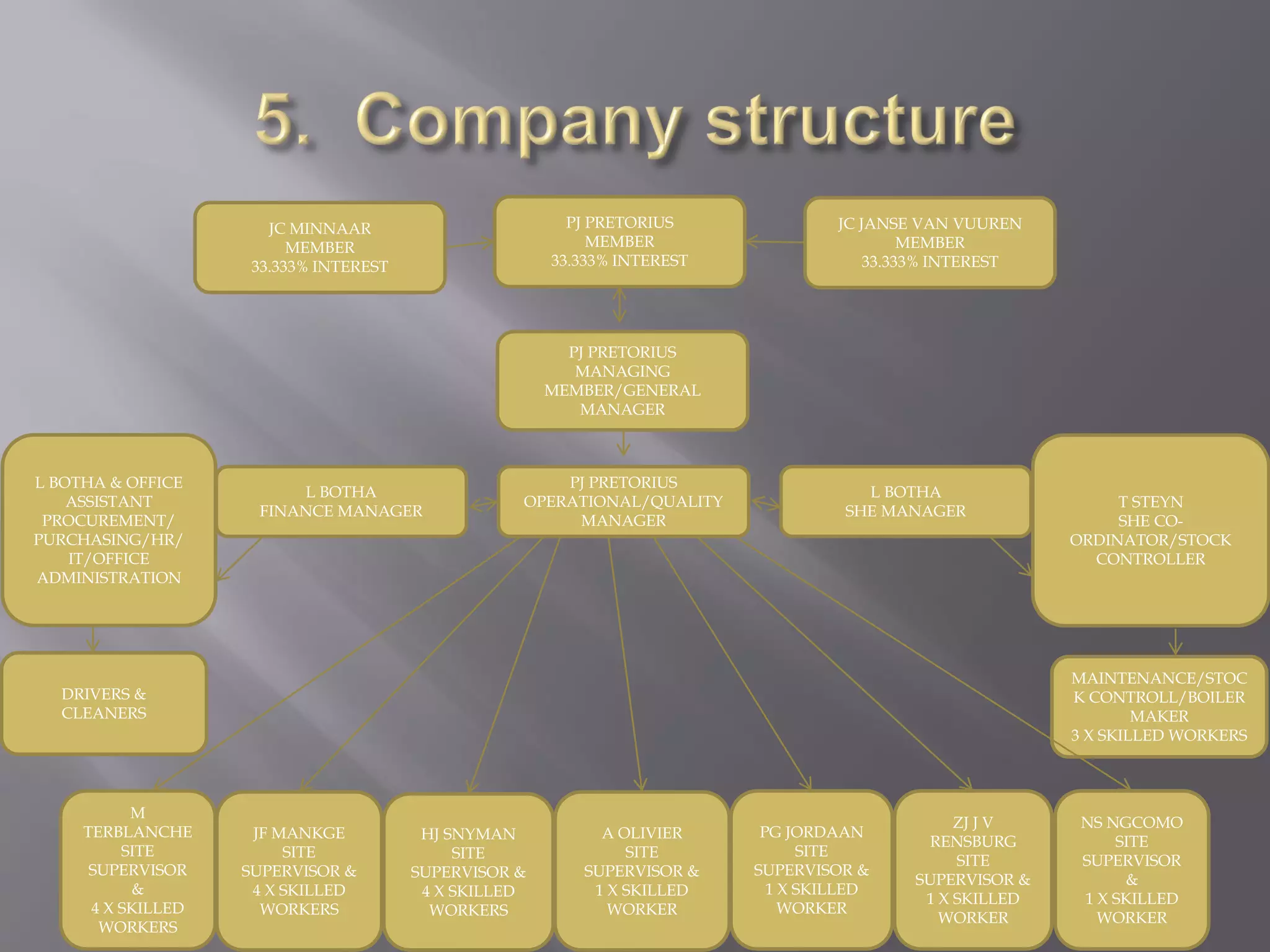

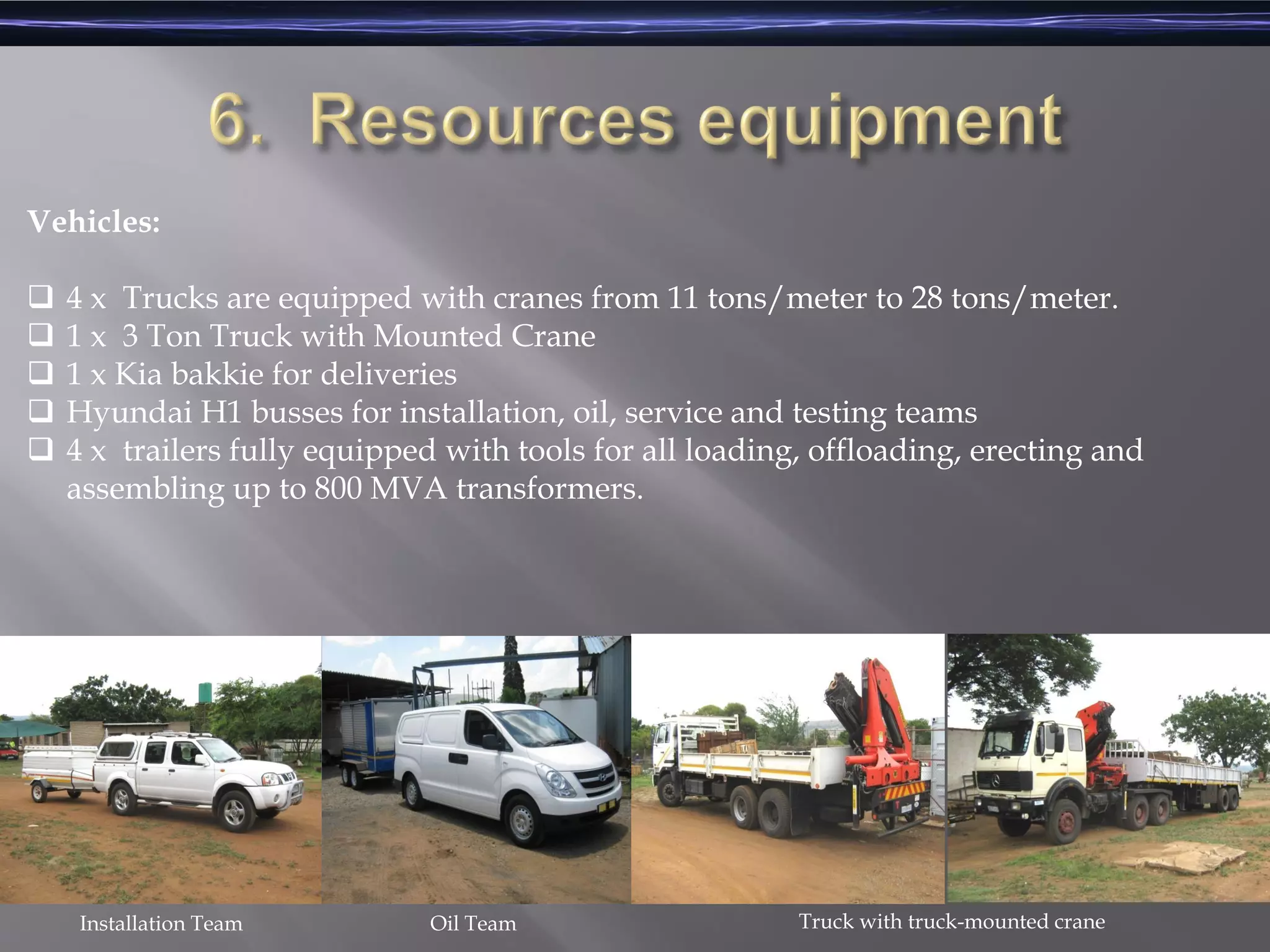

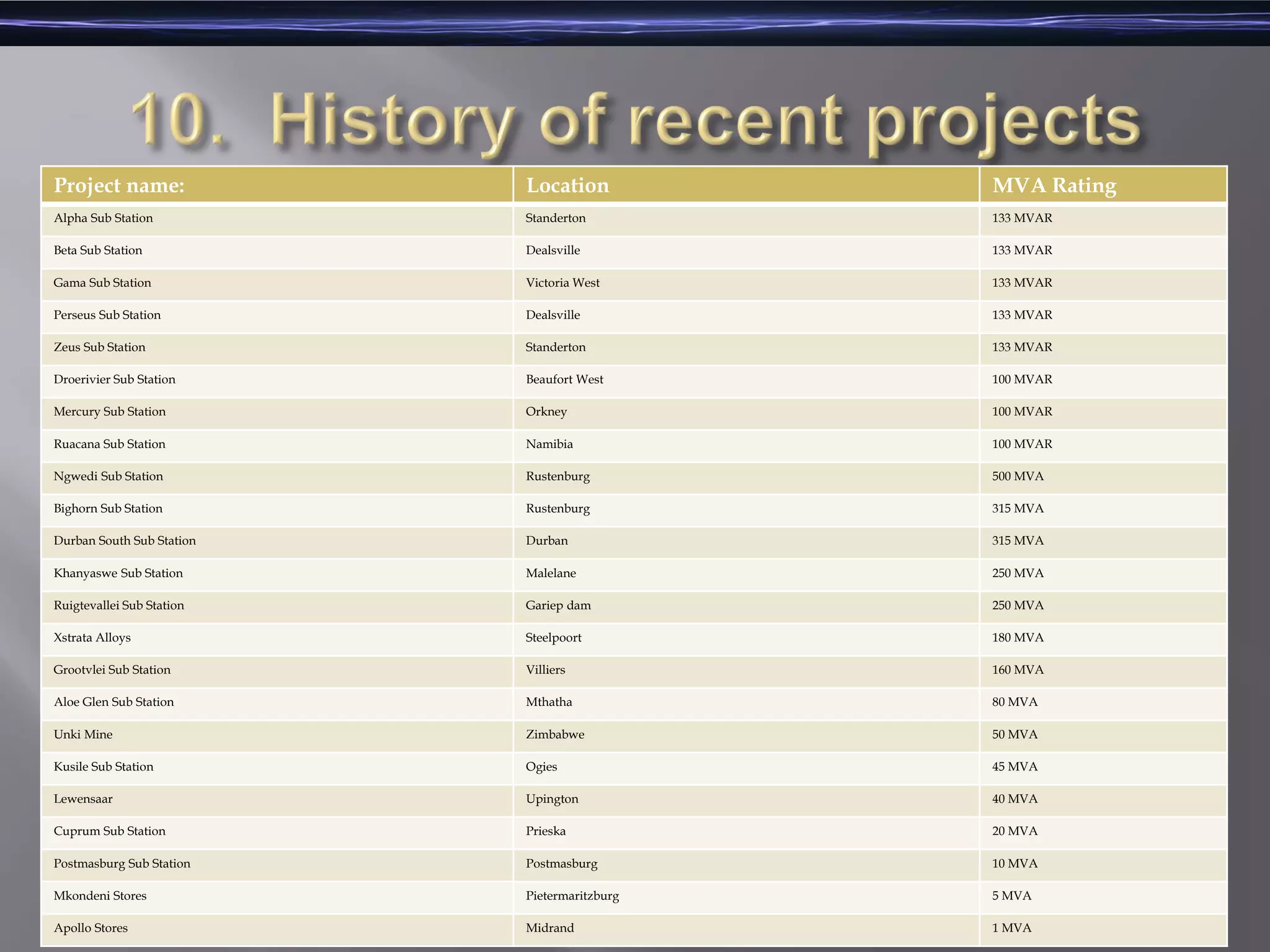

BS Rigging and Construction specializes in transporting, installing, maintaining and commissioning power transformers and reactors up to 800 MVA. The company was established in 2009 in Pretoria and has a staff of 30 covering areas such as sales, marketing, installation and safety. It has the equipment, vehicles, skilled workforce and safety standards to reliably handle projects throughout South Africa and neighboring countries.