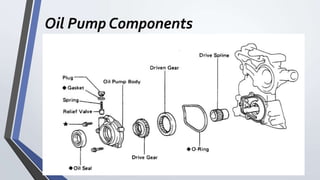

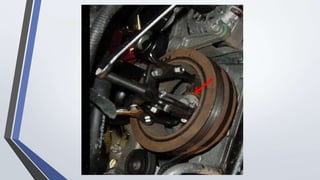

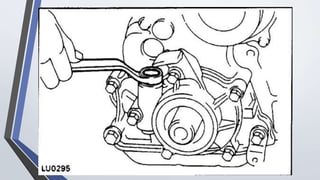

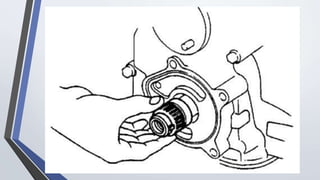

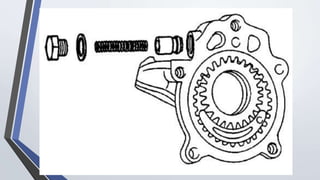

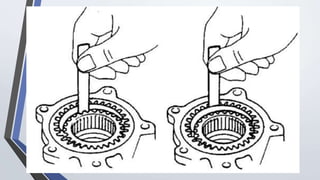

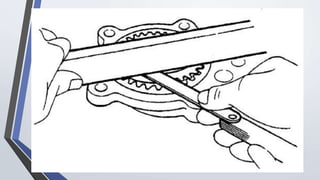

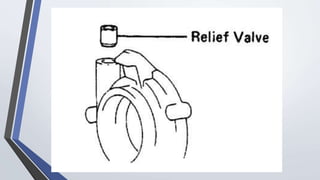

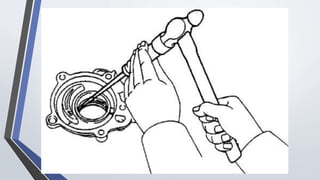

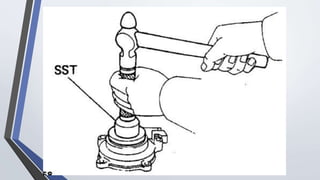

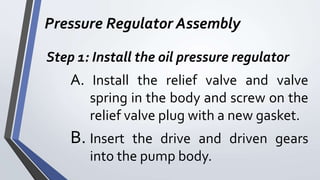

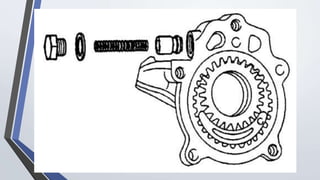

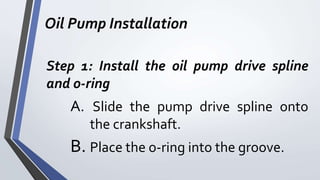

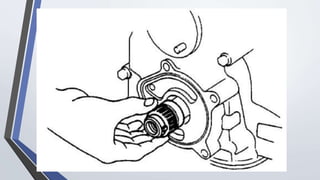

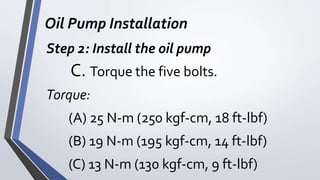

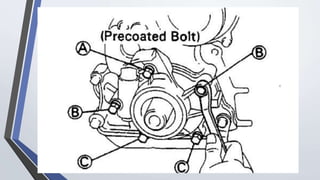

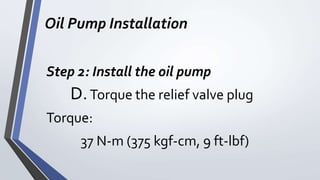

This document provides instructions for checking and testing an oil pump assembly. It begins with an introduction explaining the importance of the oil pump and its basic components and operation. The procedures then describe each step for removing, disassembling, inspecting, reassembling, and installing the oil pump. Key steps include removing the oil pan and strainer, inspecting clearances between gears and bodies, checking that the pressure regulator valve falls freely, and properly torquing bolts when reinstalling the pump. Following all outlined steps helps ensure the oil pump is functioning properly to lubricate and cool the engine.