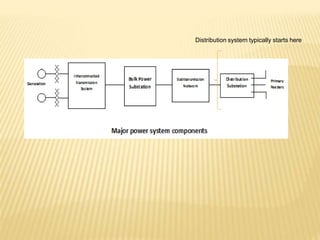

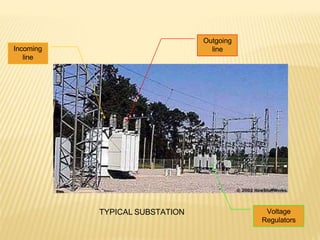

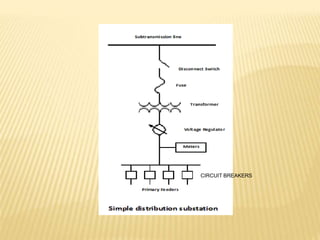

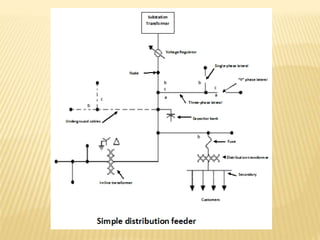

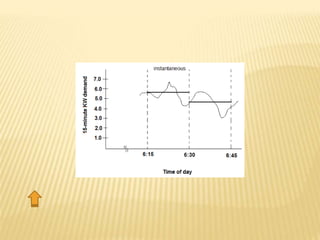

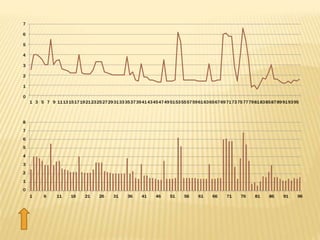

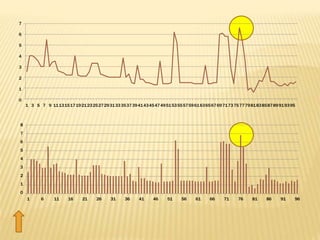

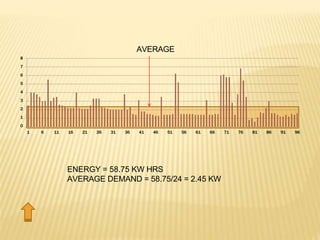

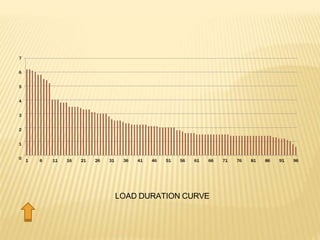

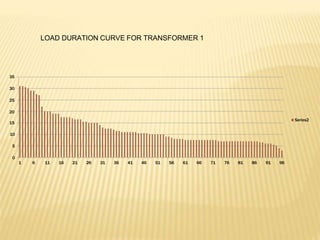

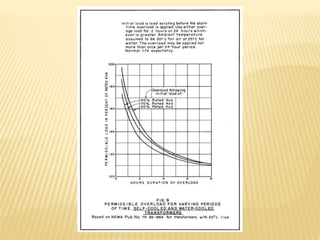

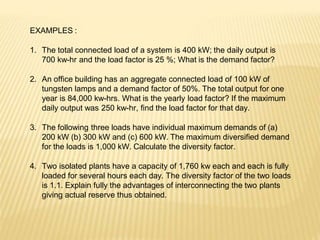

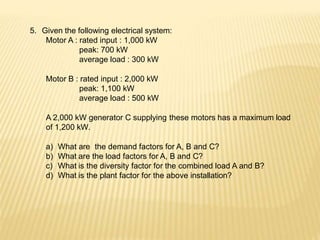

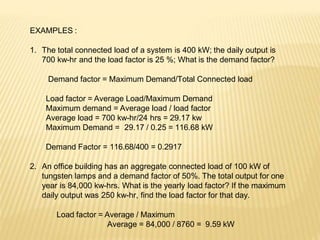

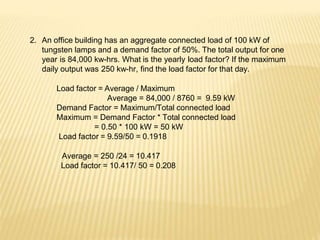

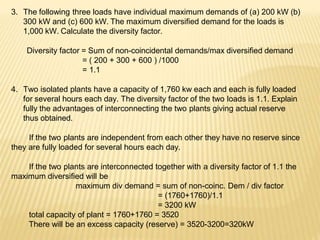

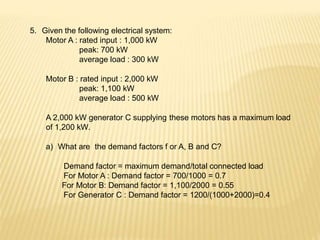

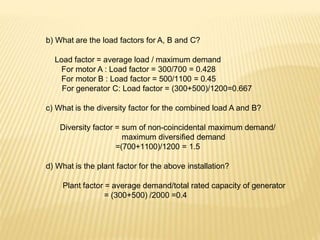

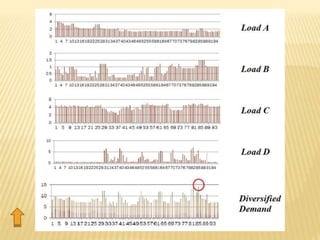

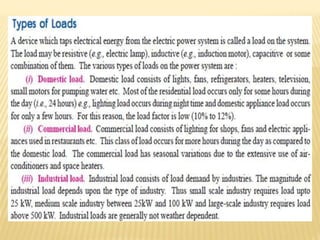

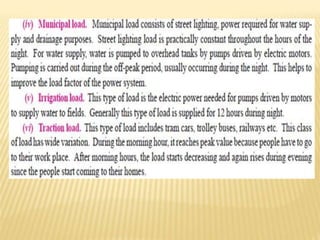

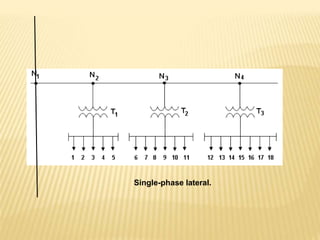

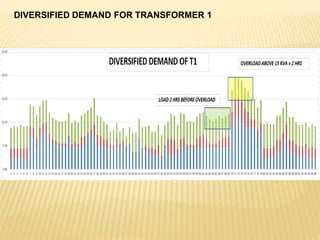

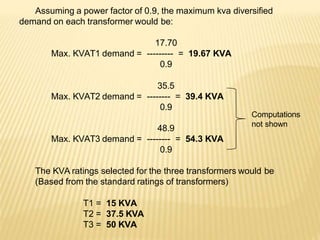

This document discusses key concepts related to electrical distribution systems and load analysis. It describes the typical components of a distribution substation including high and low side switching, transformers, voltage regulators, and protection devices. It also discusses distribution feeder maps, the characteristics of distribution lines and components, and how to model different types of loads including load graphs, demand factors, diversity factors, and other metrics. Examples are provided to demonstrate calculating various load factors and diversity factors.