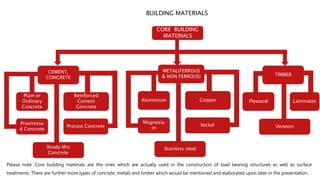

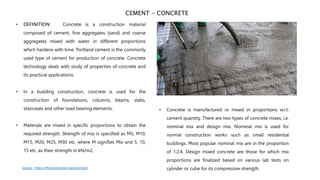

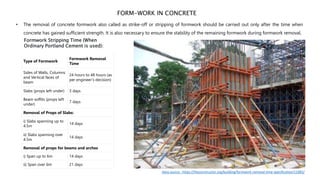

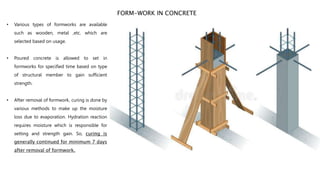

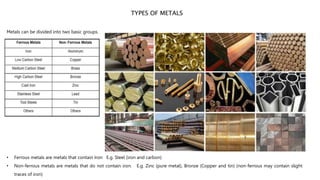

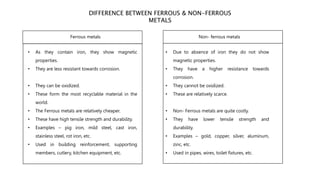

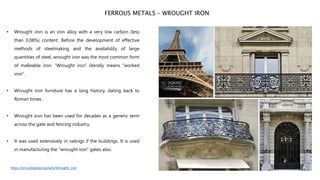

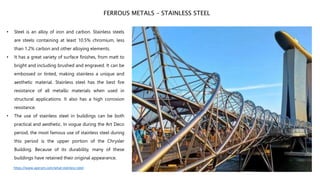

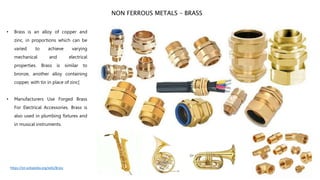

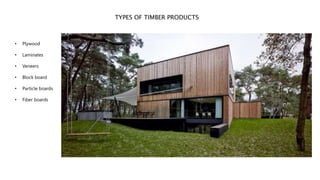

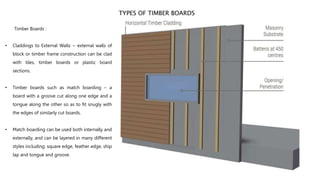

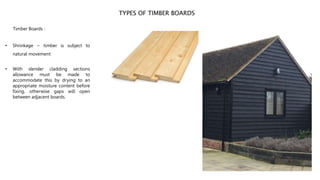

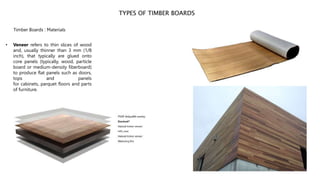

The document outlines various building materials, focusing on types of concrete and metals used in construction. It details the properties and applications of core materials like cement, concrete, and different metals (ferrous and non-ferrous), emphasizing their significance in load-bearing structures and other components. Additionally, it describes mixing methods for concrete, formwork removal times, and the categories of timber products relevant to building applications.