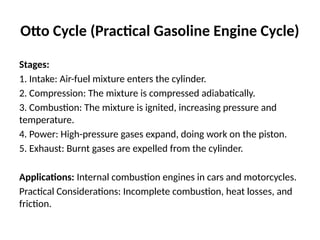

The document provides an overview of practical thermodynamic cycles, highlighting their real-world applications and implications, including the Otto, Diesel, Brayton, Rankine, and refrigeration cycles. It emphasizes the importance of considering practical limitations such as mechanical losses, heat losses, and incomplete combustion in cycle analysis to improve efficiency and design. Understanding these cycles aids in optimizing systems for performance, cost-effectiveness, and environmental sustainability.